A continuous production device and production method for synthesizing 2,2'-bipyridine

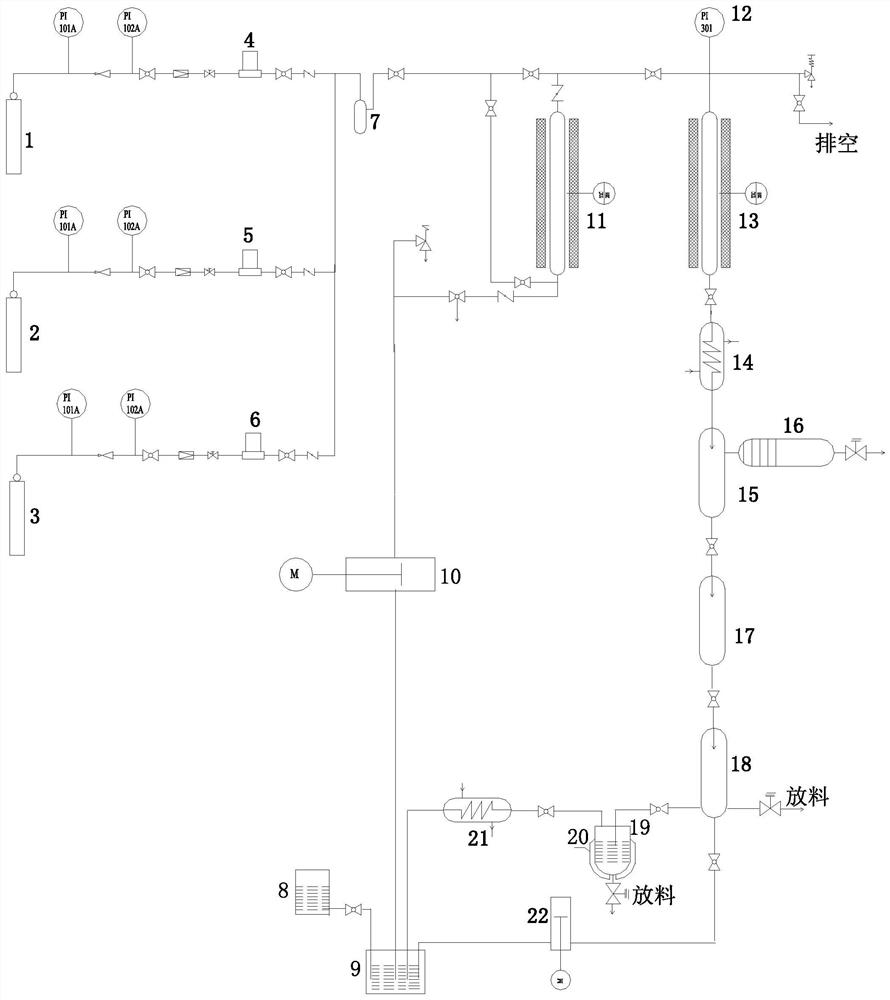

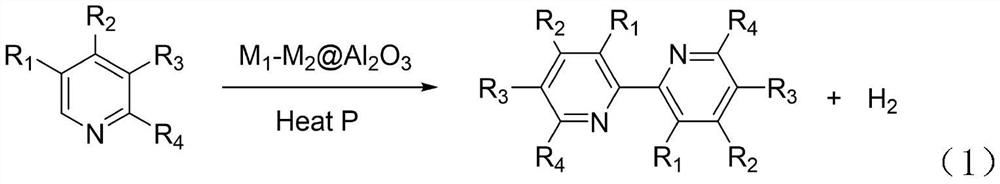

A production device and a technology for bipyridine, applied in 2 fields, can solve the problems of low single-pass conversion rate of pyridine, no practical application value, low reaction production efficiency, etc., to facilitate control of reaction conditions, realize high-efficiency production process, and improve stability. and operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Example 1: Loading method Pd@γ-Al 2 o 3 Metal nanocatalysts catalyze reactions

[0081] (1) Catalyst

[0082] The Pd content in the catalyst is 23%.

[0083] (2) Catalytic synthesis of 2,2'-bipyridine

[0084] Carry out according to aforementioned device and operation process (a), catalyst consumption is 20g. with O 2 The pressure of the reaction system was adjusted to 15Mpa; the temperature of the preheater was 300°C, the reaction temperature was 800°C, and the delivery rate of pyridine was 40ml / min, so that the yield of 2,2'-bipyridine was 5%.

Embodiment 2

[0085] Example 2: Loading method Pd-Cu@γ-Al 2 o 3 Metal nanocatalysts catalyze reactions

[0086] (1) Catalyst

[0087] The Pd content in the catalyst is 23%, Pd:Cu=3:1 (molar ratio).

[0088] (2) Catalytic synthesis of 2,2'-bipyridine

[0089] Carry out according to aforementioned device and operation process (a), catalyst consumption is 20g. with O 2 The pressure of the reaction system was adjusted to 15Mpa; the temperature of the preheater was 300°C, the reaction temperature was 800°C, and the delivery speed of pyridine was 40ml / min, so that the yield of 2,2'-bipyridine was 8%.

Embodiment 3

[0090] Example 3: Loading method Pd-Ni@γ-Al 2 o 3 Metal nanocatalysts catalyze reactions

[0091] (1) Catalyst

[0092] The Pd content in the catalyst is 23%, Pd:Ni=2:1 (molar ratio).

[0093] (2) Catalytic synthesis of 2,2'-bipyridine

[0094] Carry out according to aforementioned device and operation process (a), catalyst consumption is 20g. with O 2 The pressure of the reaction system was adjusted to 15Mpa; the temperature of the preheater was 300°C, the reaction temperature was 800°C, and the delivery speed of pyridine was 40ml / min, so that the yield of 2,2'-bipyridine was 28%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com