Local strength-varying design method for automobile parts

A technology of auto parts and design methods, applied in the field of heat treatment, to achieve the effect of improving the level of energy absorption, stabilizing the plastic deformation of axial crushing, and improving the versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A kind of technology of auto parts local variable strength design method comprises the following steps:

[0028] Step 1: Determine the impact direction of the component, and calculate the equivalent width of the cross section of the component perpendicular to the impact direction, material thickness, and yield strength of the base metal;

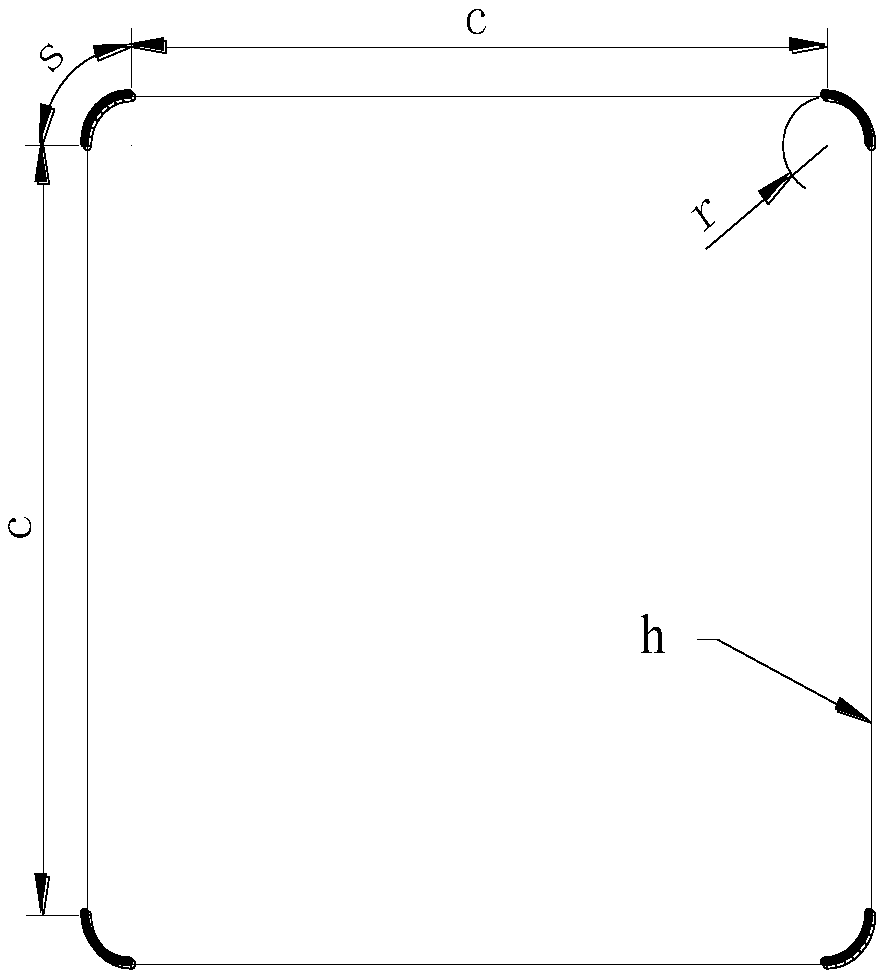

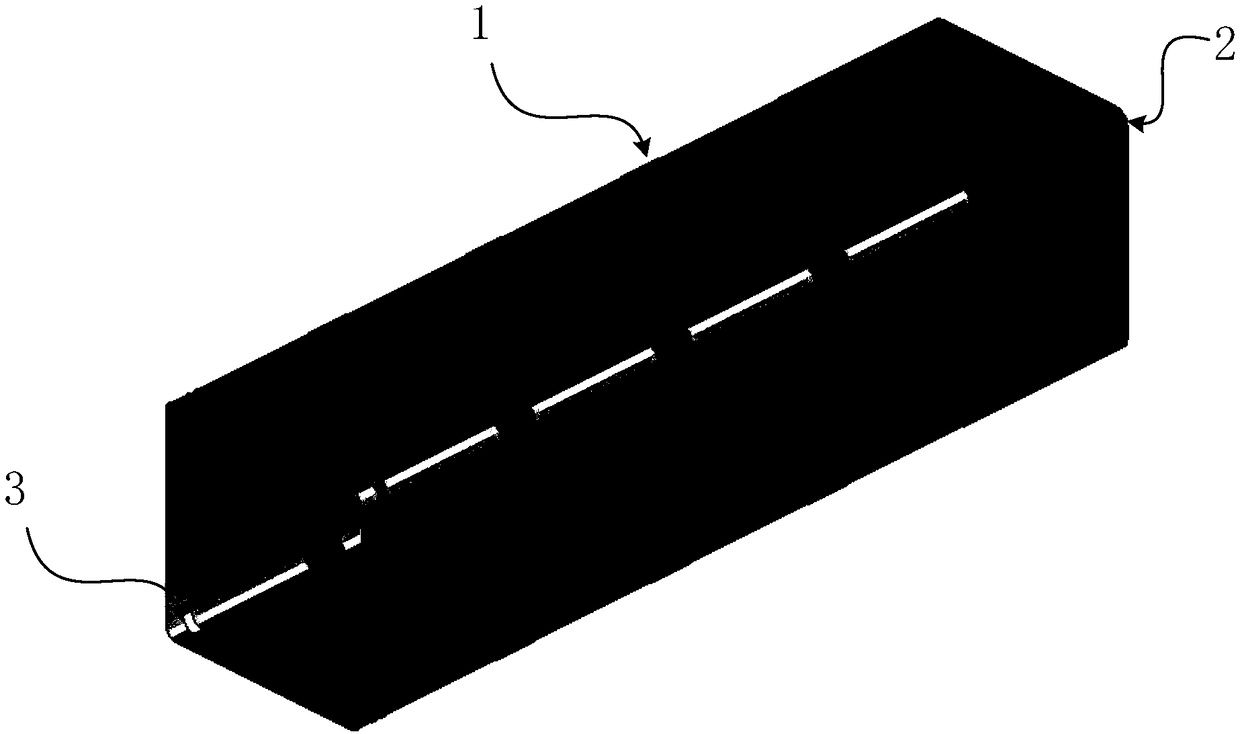

[0029] Step 2: Determine whether there is an edge perpendicular to the impacted direction on the component, and if so, perform laser quenching on the edge; if figure 1 The shown arc width for quenching the edge satisfies the formula: That is, according to this formula, the arc width during edge quenching can take into account the equivalent width c of the cross section of the part and the thickness h of the steel plate. This is to realize that strip-shaped parts can improve their strength when receiving lateral impacts. For example, if they are applied in the ABC column of a car body, they can effectively improve the impact protecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com