Pipe gallery supporting structure based on urban underground pipe gallery

A technology of integrated pipe gallery and support structure, applied in underwater structures, infrastructure engineering, pillars/supports, etc., can solve the problems of high quality requirements, tight construction period, long battle lines, etc., to achieve good integrity, reduce quantity, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

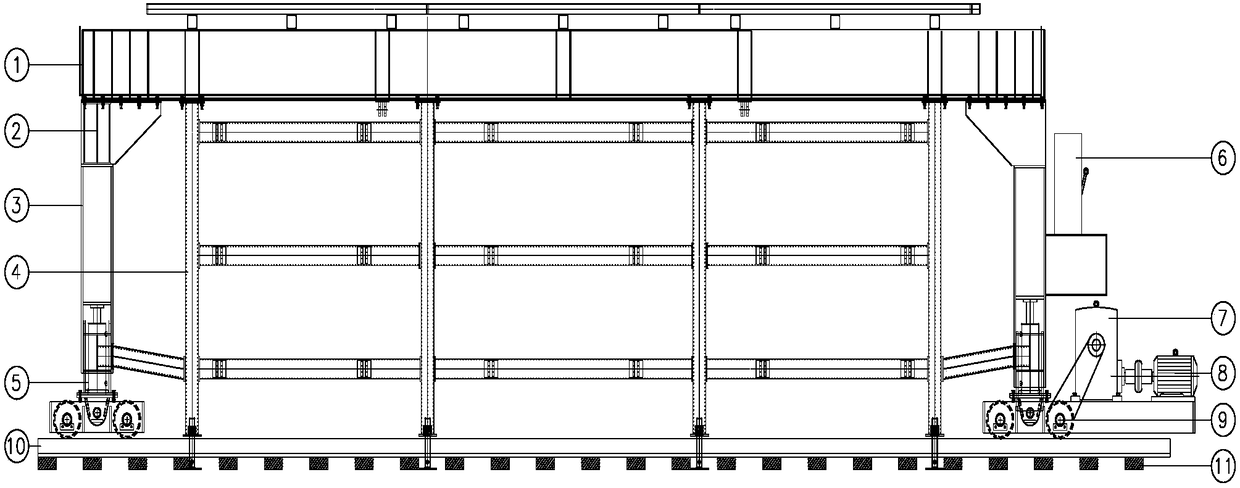

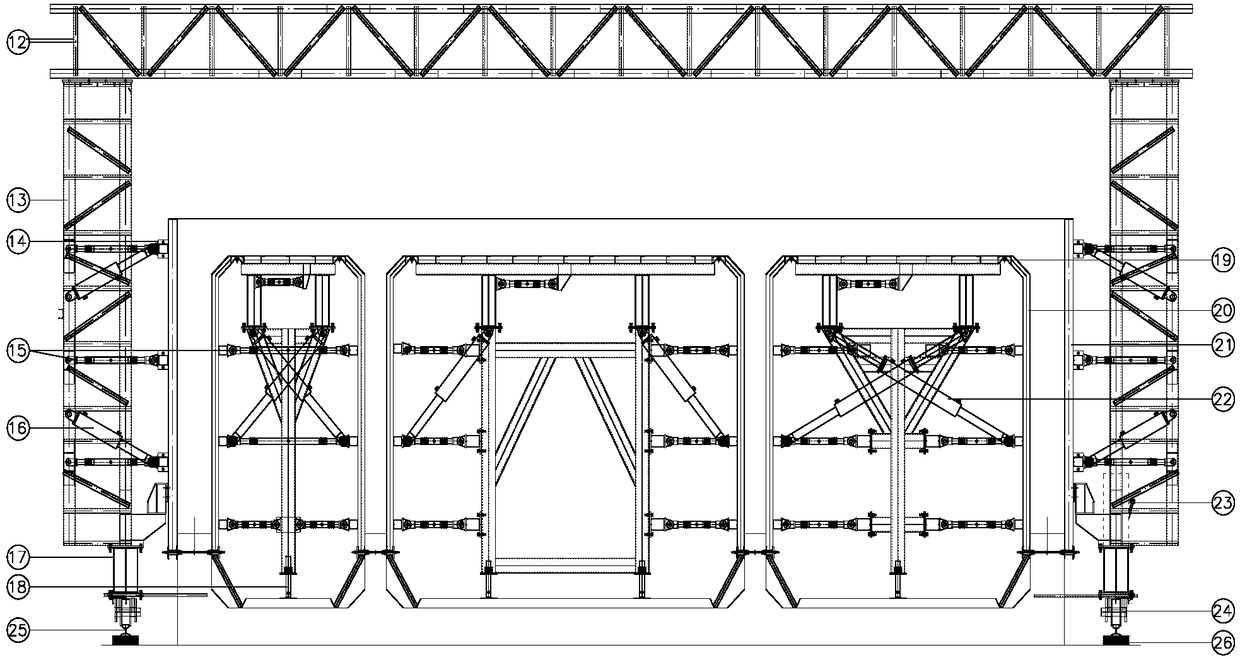

[0017] exist figure 1 , figure 2 As shown, the present invention comprises upper longitudinal beam 1, inner mold gantry crossbeam 2, inner mold gantry pillar 3, inner mold auxiliary gantry pillar 4, four inner mold jacking hydraulic presses 5 (number is calculated by one cabin) , if the number of cabins is large, it will be calculated as 4 times the number of cabins), internal mold hydraulic pump station 6, four reducers 7, four motors 8, walking wheels 9, two internal mold rails 10, internal mold wooden square 11, Outer mold gantry beam 12, outer mold gantry pillar 13, side longitudinal beam 14, several lateral screw screws 15, eight outer mold side top hydraulic presses 16, lower longitudinal beam 17, several vertical screw screws 18, inner Top steel formwork 19, inner wall steel formwork 20, outer wall steel formwork 21, four inner formwo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com