Plate for building and application thereof

A technology for construction and board materials, which is applied in the direction of buildings, building components, building structures, etc. It can solve problems such as cracking and affecting sound insulation, and achieve the effects of simple and convenient operation, increased production, and reduced processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

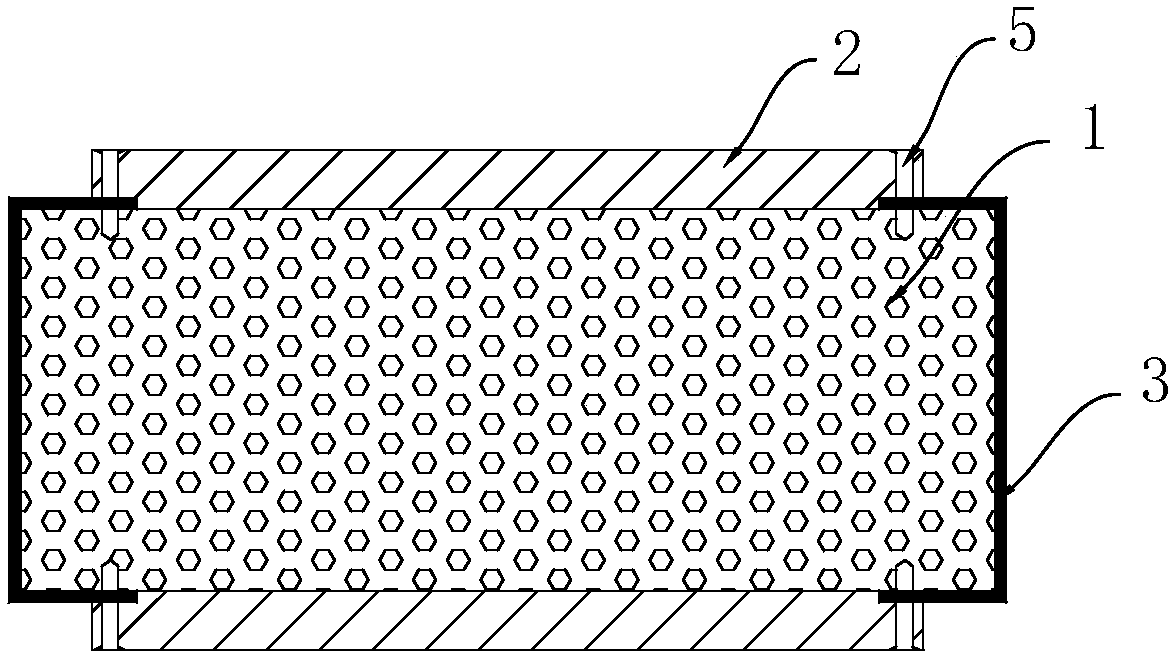

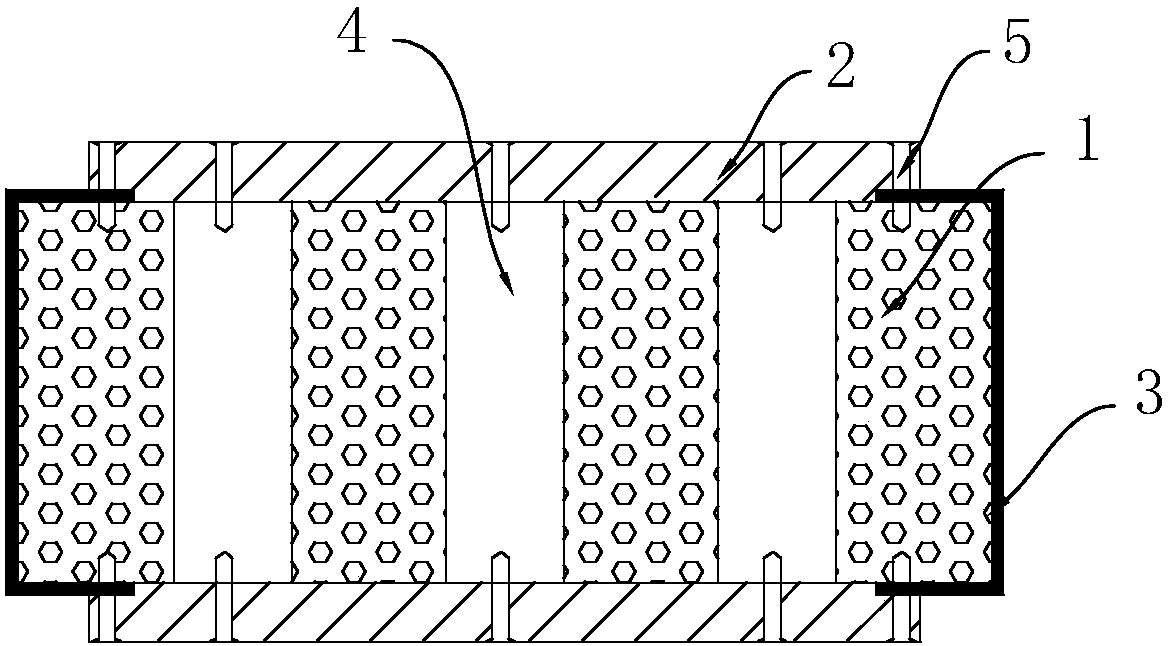

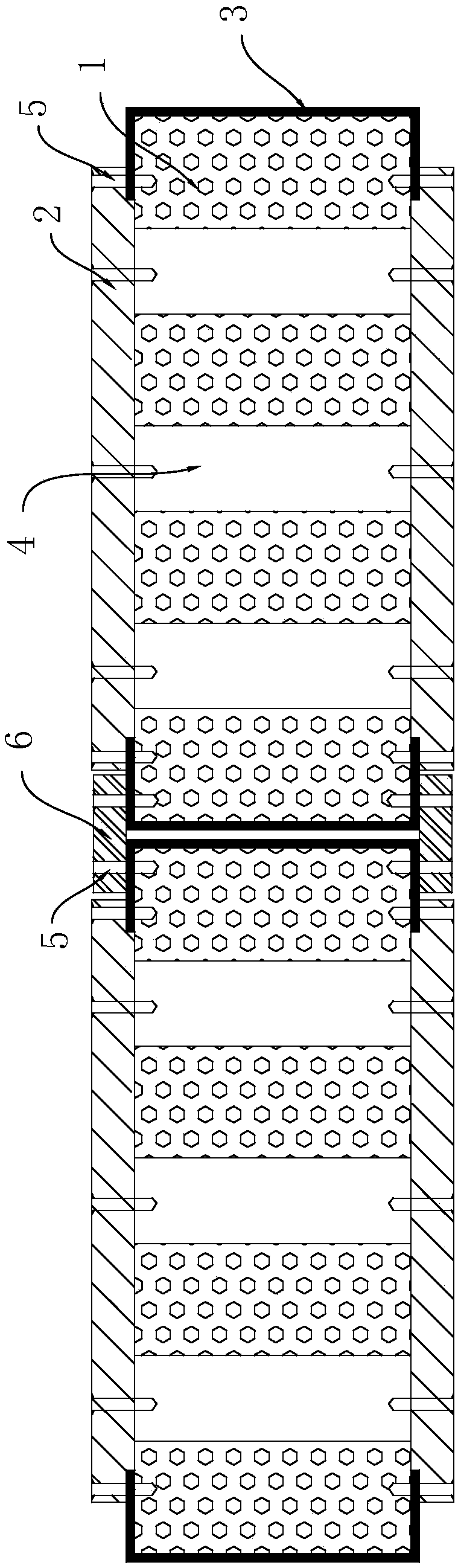

[0030] Example: as figure 1 As shown, the building board is characterized in that it comprises a core layer 1, a surface layer 2 respectively covering both sides of the core layer, the two sides of the surface layer are respectively provided with side-wrapped light steel keels 3, and the core layer The two ends of the side wrapping light steel keel are respectively placed in the groove of the side wrapping light steel keel. The folded edges on the edge light steel keel form a stepped structure, the surface of the surface layer forms an upper stepped surface, and the surface of the folded edge forms a lower stepped surface. When in use, multiple sheets are spliced to form grooves on the surface of the spliced part (that is, the surface in the same direction as the surface layer).

[0031] During processing, a core layer cavity is formed between the side-wrapped light steel keel and the surface layer, and both ends of the core layer cavity in the length direction are closed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com