Valve operating manipulator

A technology of valve operation and manipulator, applied in the direction of valve operation/release device, mechanical equipment, valve details, etc., can solve the problems of inability to operate multiple types of valves, low efficiency, high cost, etc., to shorten valve operation time and save energy Consumption, high adaptability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

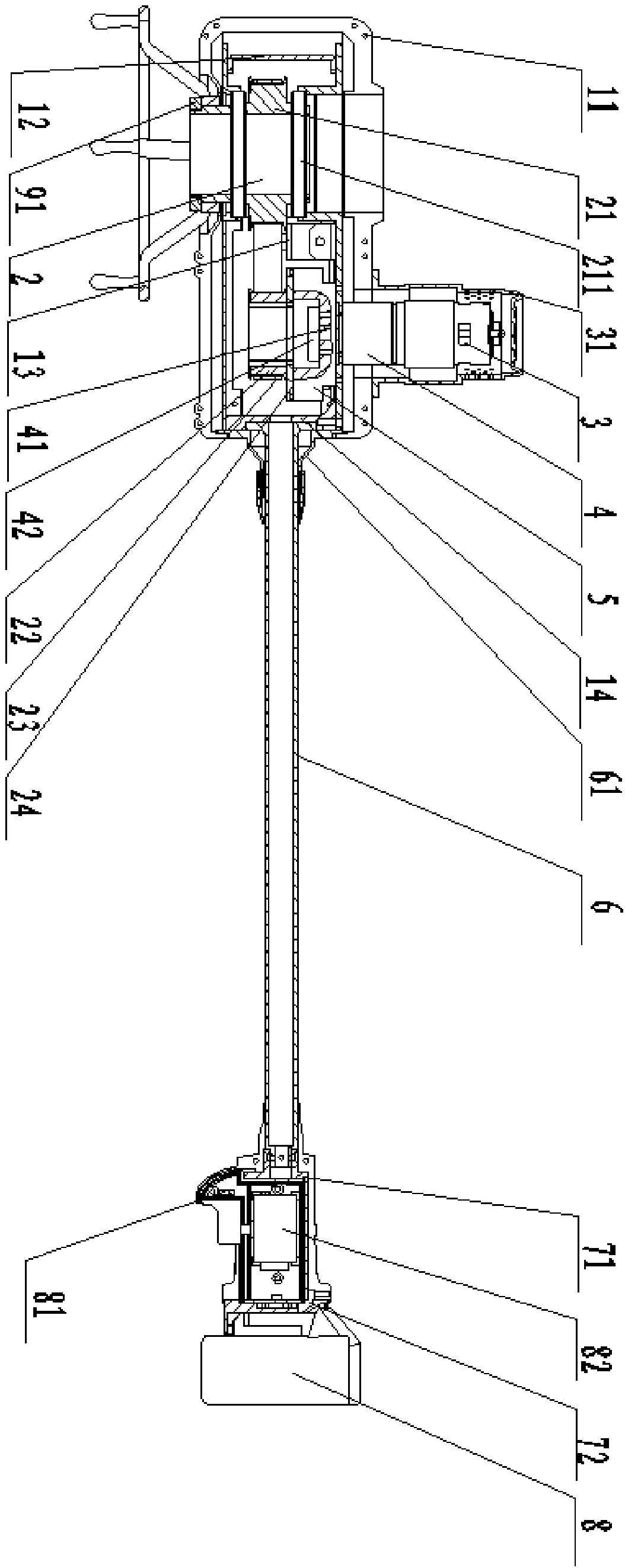

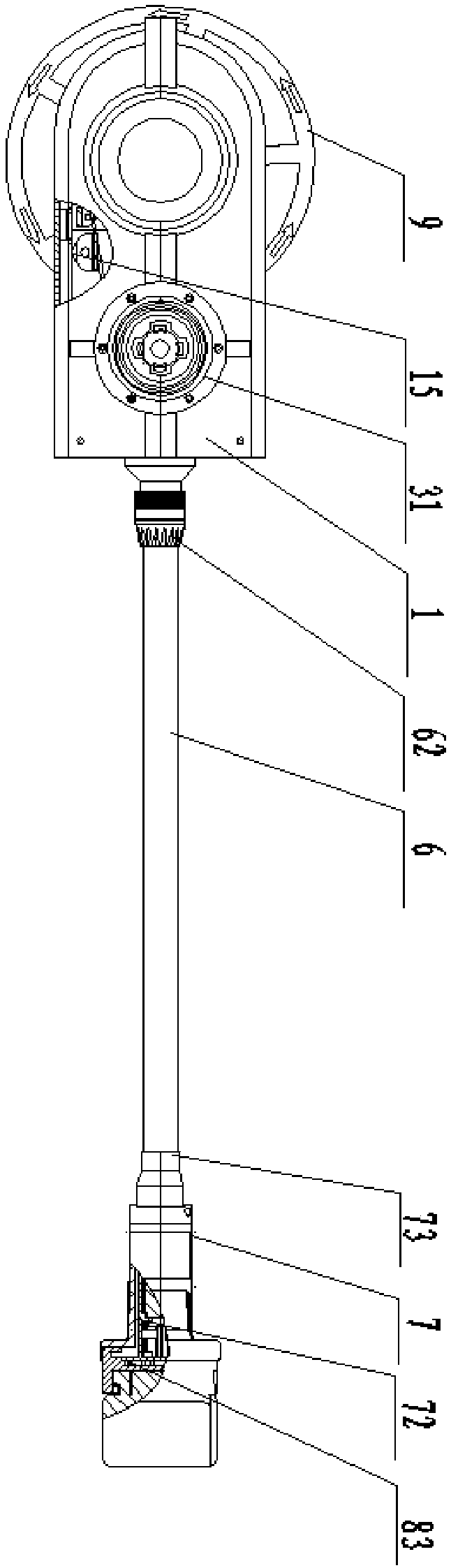

[0025] refer to Figure 1 to Figure 2 A valve operating manipulator of the present invention includes a valve driving front end 1, a transmission mechanism 2, a motor 3, a planetary gear reducer 4, a harmonic reducer 5, a hand lever 6, a power control tail 7, a battery 8 and a valve adapter 9, The two ends of the handle bar 6 are respectively provided with a valve driving front end 1 and a power control tail 7, and a motor 3 is installed on the valve driving front end 1, and the motor 3 passes through a planetary gear reducer 4 and a harmonic reducer 5 Connected with the transmission mechanism 2, the transmission mechanism 2 controls the rotation of the valve adapter 9, one end of the power control tail 7 is connected with the handle bar 6, and the other end of the power control tail 7 is equipped with a battery 8. The transmission mechanism 2 includes a driven wheel 21, a driving wheel 22, a synchronous belt 23 and a driving wheel connector 24, and the harmonic speed reducer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com