Cyclic shear tester and test method for rock mass structural planes

A shear test and structural surface technology, which is applied in the direction of using a stable shear force to test the strength of materials, instruments, scientific instruments, etc. To achieve the effect of automatic monitoring and whole process recording, reducing human disturbance, and adjustable and controllable frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

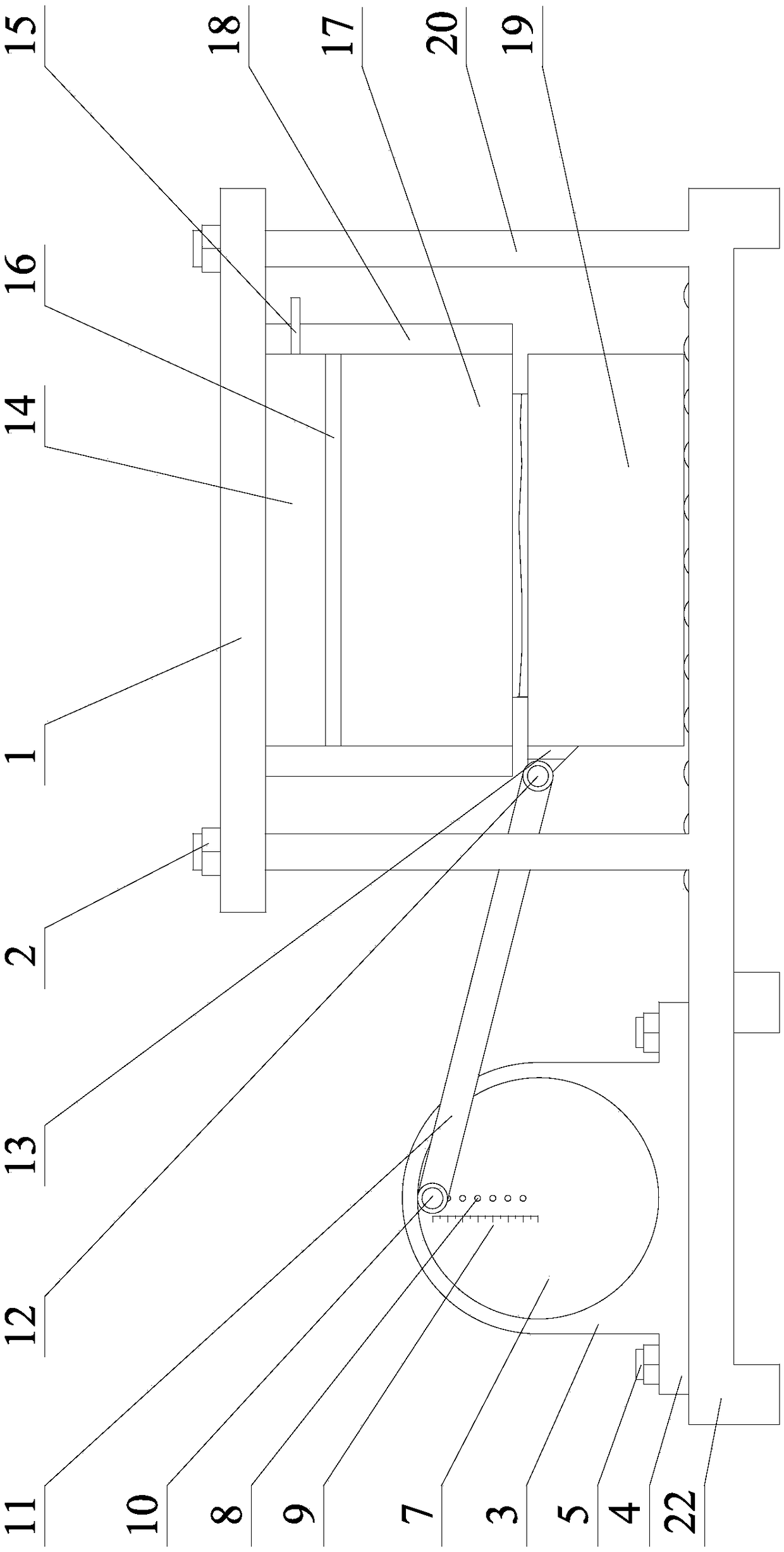

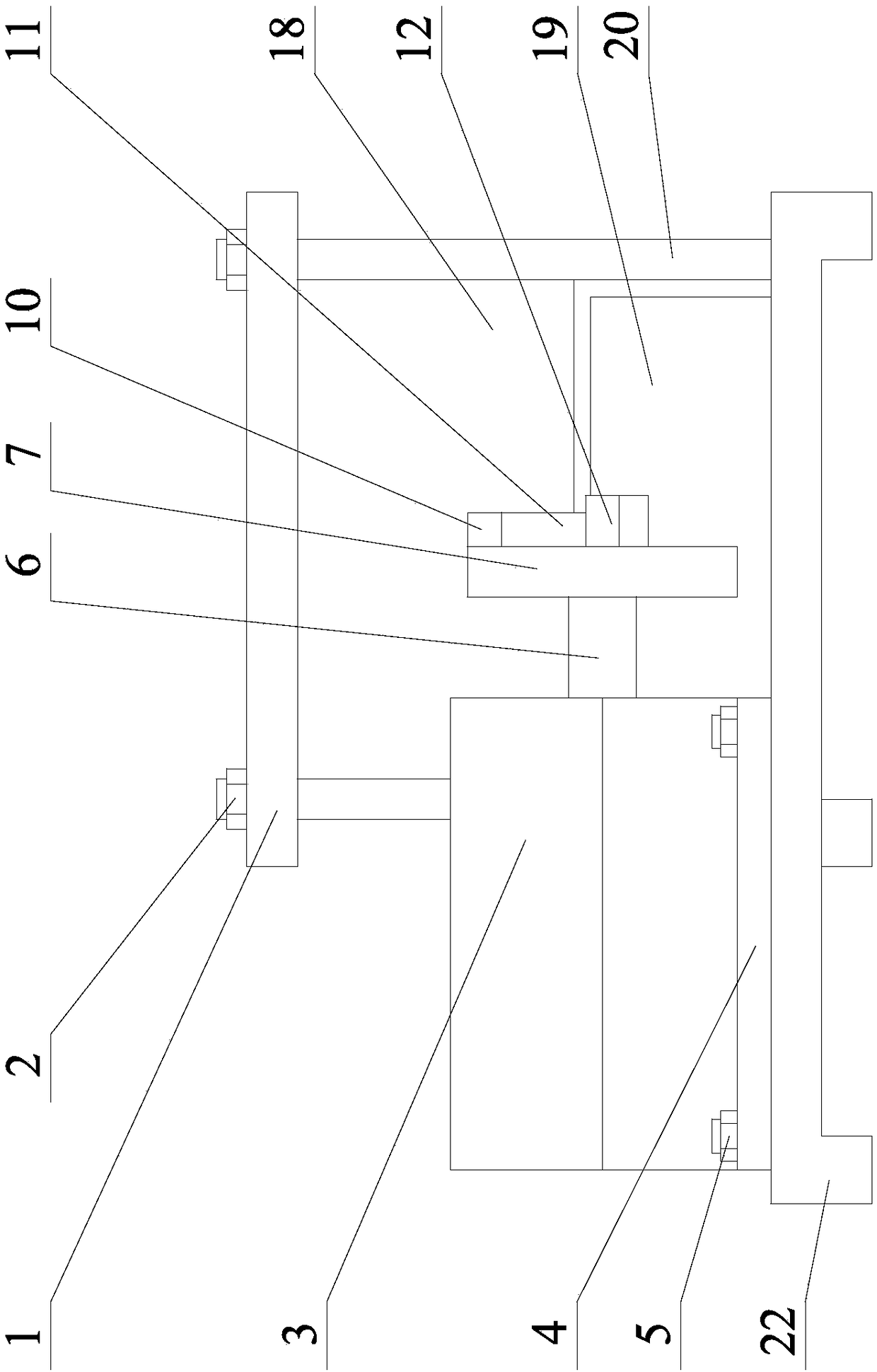

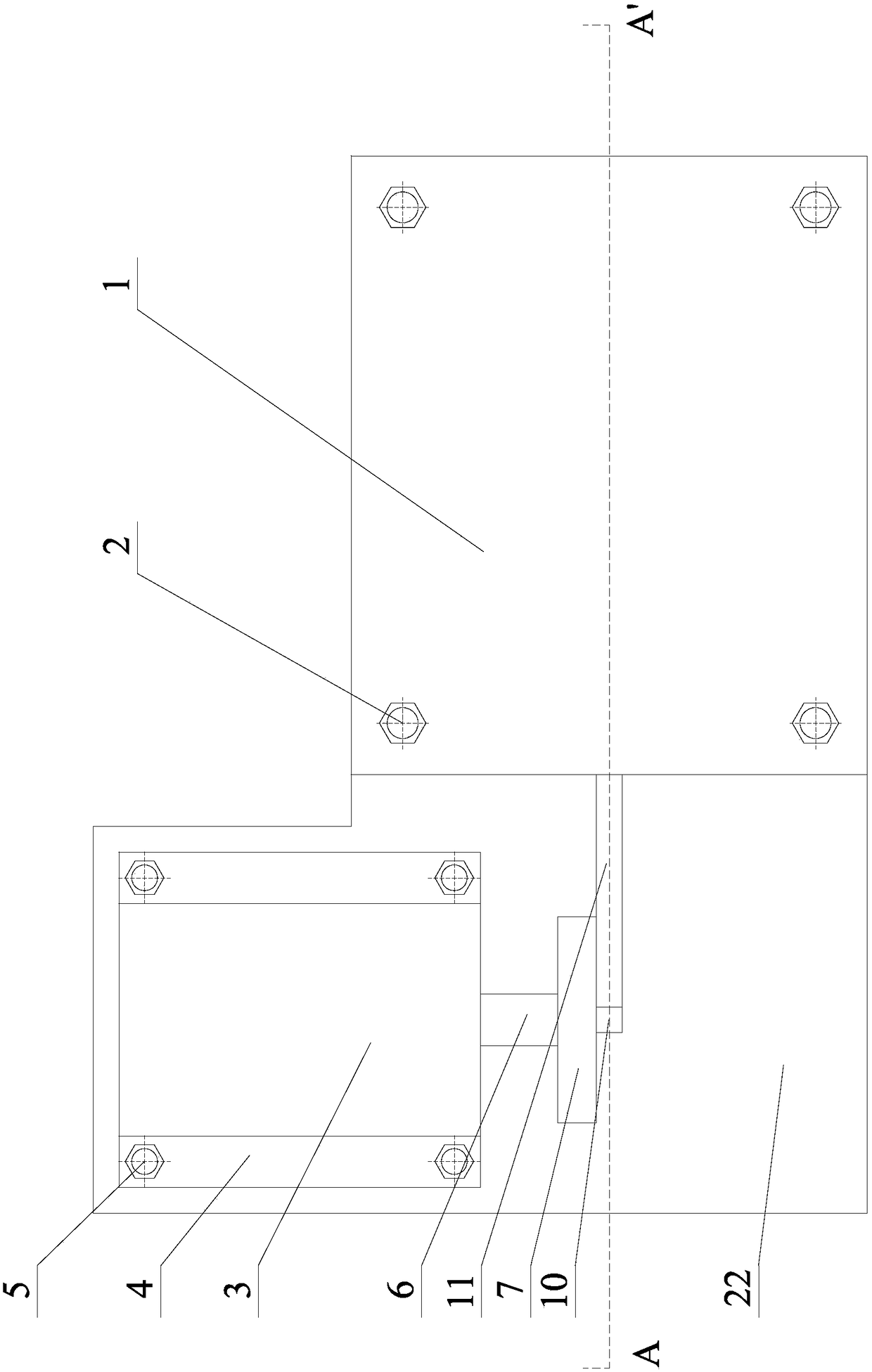

[0041] Refer to attached picture. A cyclic shear tester for a rock mass structural surface provided by the present invention comprises a foundation support system, a cyclic load system, a normal load system and a shear test system, the cyclic load system, the normal load system and the The shear test systems are all installed in the foundation support system, the cyclic load system provides cyclic shear load for the test through the kinetic energy of the AC servo motor 3, and the normal load system provides a stable load for the test through the digitally controlled flat jack 14. Normal load, the shear test system protects the rock mass structural surface sample 100 through the cyclic shear box 19 and the fixed shear box 17 and carries out the cyclic shear test, the fixed shear box 17 is on the upper part, and the cyclic shear box 19 is located below the fixed shear box 17, and the positions of the fixed shear box 17 and the cyclic shear box 19 facing each other are provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com