Ultrasonic phased array detection method for polyethylene electric melting joint

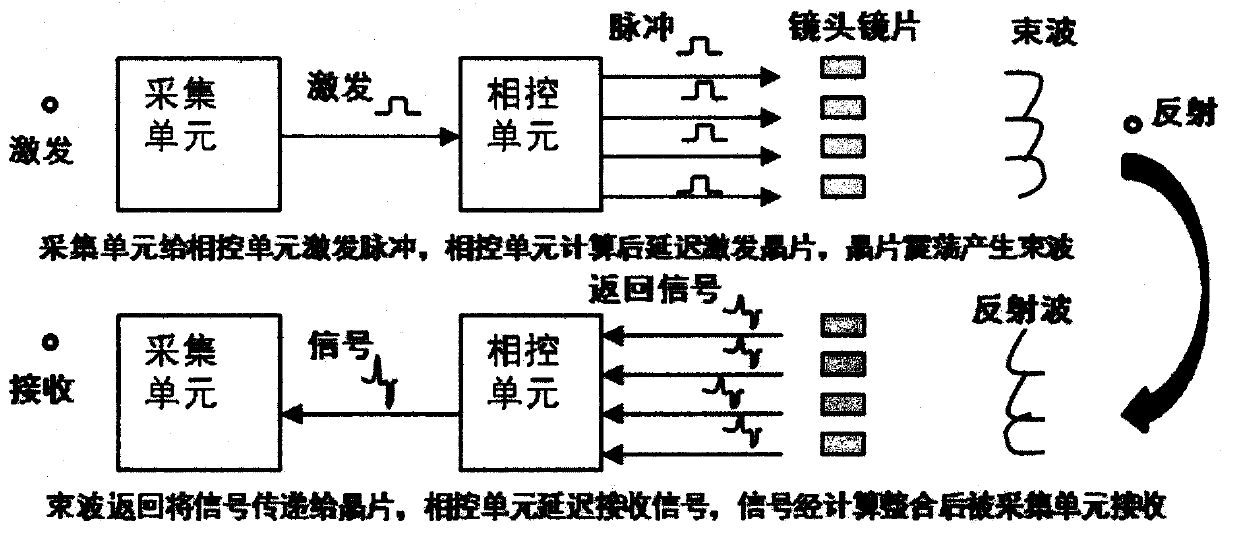

A technology of electrofusion joint and detection method, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and measuring devices, etc. , difficulties in retrospecting and checking, etc., to achieve the effect of reducing human interference factors, improving equipment work efficiency, and improving detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Step 1: Clean the surface of the welding area of the polyethylene electrofusion joint to be tested 360° to ensure that there is no interference from impurities.

[0018] Step 2: Select the corresponding number of long or short connecting rods according to the outer diameter of the polyethylene electrofusion joint to be detected, and assemble the chain scanner.

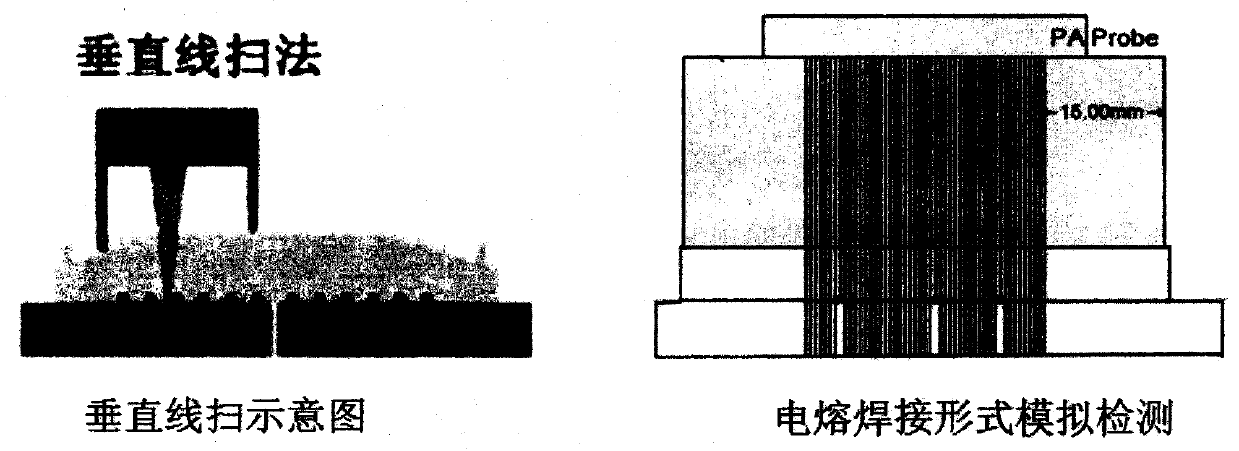

[0019] Step 3: Select a phased array probe with a frequency of 2.25-2.50 MHz according to the detection process of polyethylene electrofusion joint workpieces, and install a phased array pulse probe on a specially developed zero-degree water immersion wedge.

[0020] Step 3: Lock the checker and introduce coupling agent from the wedge interface. If conditions permit, hydroxymethyl cellulose aqueous solution is preferred as the coupling agent to ensure good acoustic coupling between the workpiece and the probe.

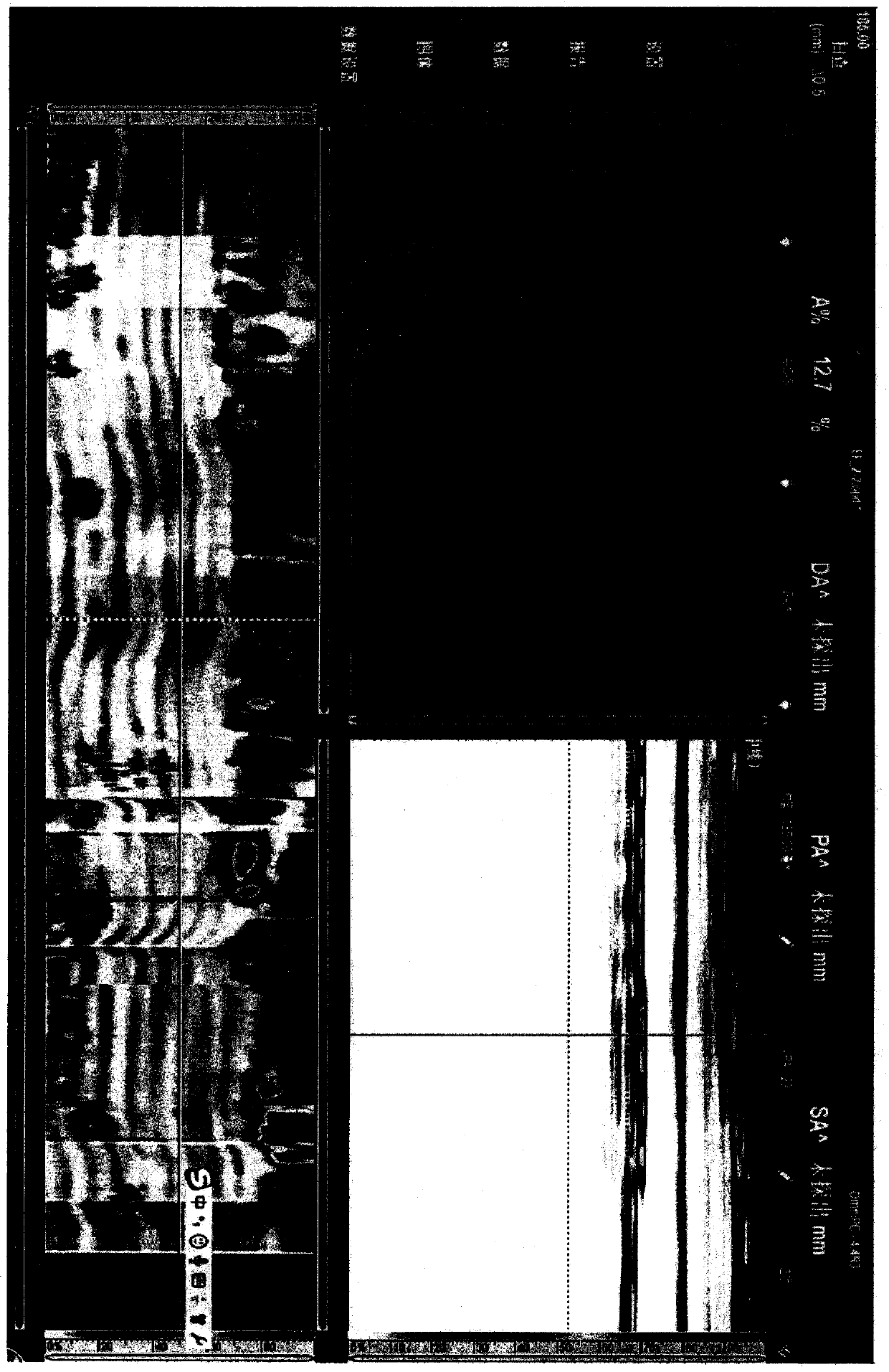

[0021] Step 4: Use the zero-degree vertical linear focus rule to set the focus depth to 20mm, scan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com