Control method of battery case in electric vehicle

An electric vehicle and control method technology, applied in battery temperature control, secondary battery, battery pack components and other directions, can solve the problems of cooling fan consuming battery capacity, poor cooling effect, reducing battery effective utilization efficiency, etc. Safety performance and service life, the effect of enhancing the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

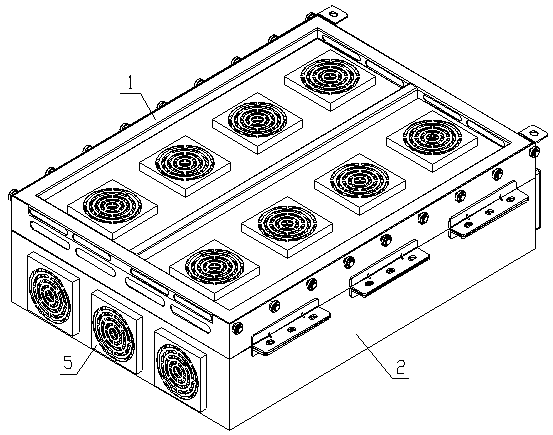

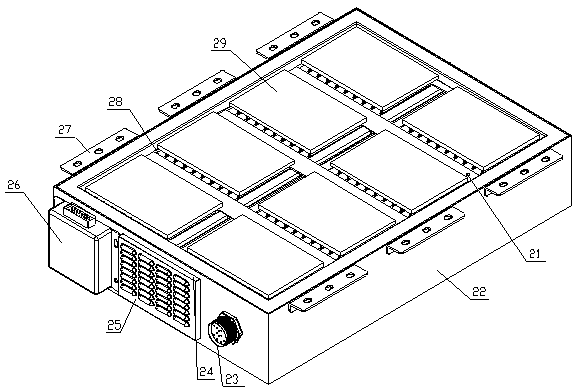

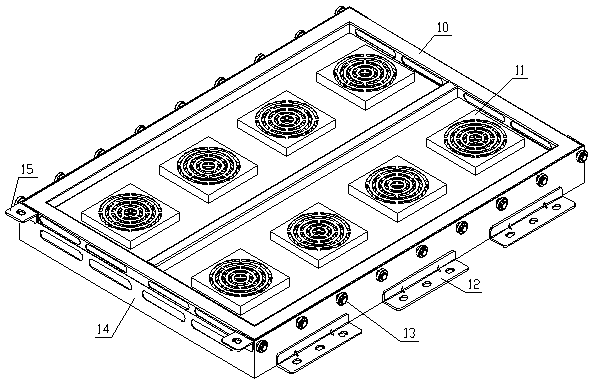

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an electric vehicle battery box according to the present invention includes a battery pack 28, a water cooling assembly 29, a high thermal conductivity aluminum plate 3, a heat pipe radiator 4, a battery box (including a battery box main body 2, a cooling box 1), Control box 26, electrical connection port 23, cooling fan (side cooling fan 5, top cooling fan 11), thermocouple 21, etc.

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the battery box is composed of a cooling box 1 and a battery box main body 2, which are connected by locking bolts through the first connecting angle plate 12 and the second connecting angle plate 27; the high thermal conductivity aluminum plate 3 is placed in the cooling box 1 Between the main body of the batter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com