Stator permanent magnet type double-rotor magnetic field modulation motor and design method thereof

A magnetic field modulation and design method technology, applied in the direction of magnetic circuit rotating parts, electrical components, electromechanical devices, etc., can solve the problems of poor heat dissipation conditions, high temperature and easy demagnetization of rare earth permanent magnets, etc., to reduce the use of copper wires and improve weak Magnetic properties and the effect of reducing copper loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

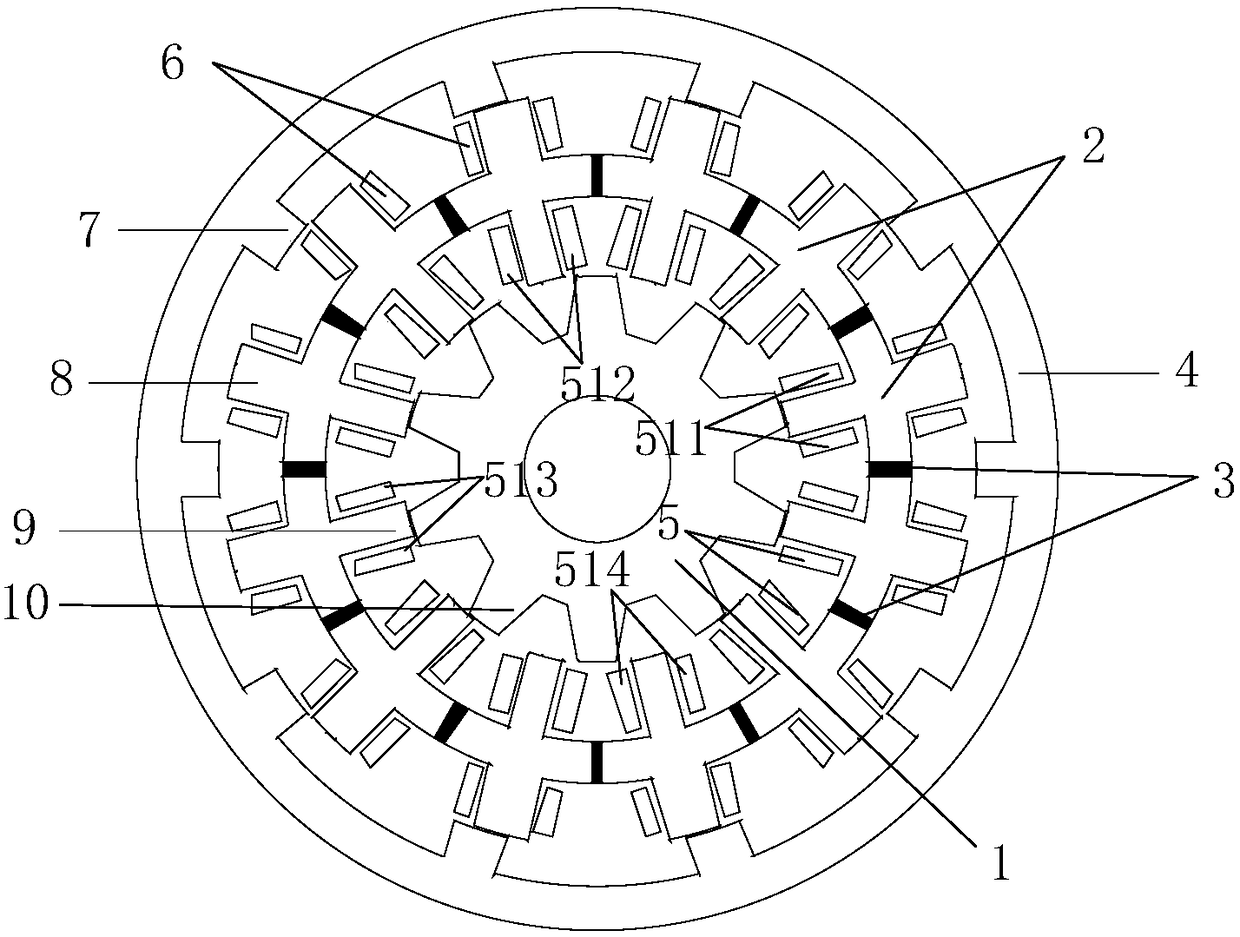

[0048] like figure 1 , a stator permanent magnet type dual-rotor magnetic field modulation motor of the present invention and a design method thereof, the motor comprises an inner rotor (1), a stator (2) and an outer rotor (4) from the inside to the outside, the inner rotor (1) and There are air gaps between the stators (2), the stators (2) and the outer rotor (4). Each yoke of the stator (2) is embedded with radial permanent magnets (3), all of which adopt tangential excitation, and the N poles and S poles of the radial permanent magnets (3) are arranged alternately along the circumference; the outer teeth of the stator (8), the inner teeth of the stator (9) are straight tooth structures, the inner windings (5) and outer windings (6) are arranged in the slots of the stator (2), and the inner rotor (1) and outer rotor (4) are both made of silicon steel An outer rotor tooth (7) and an inner rotor tooth (10) of a salient pole tooth structure formed by lamination of sheets. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com