Heater

A heater and controller technology, used in heating elements, ohmic resistance heating parts, electric heating devices, etc., can solve the problems of long reaction time and inability to cut off the power supply in time, and achieve the effect of reducing the space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

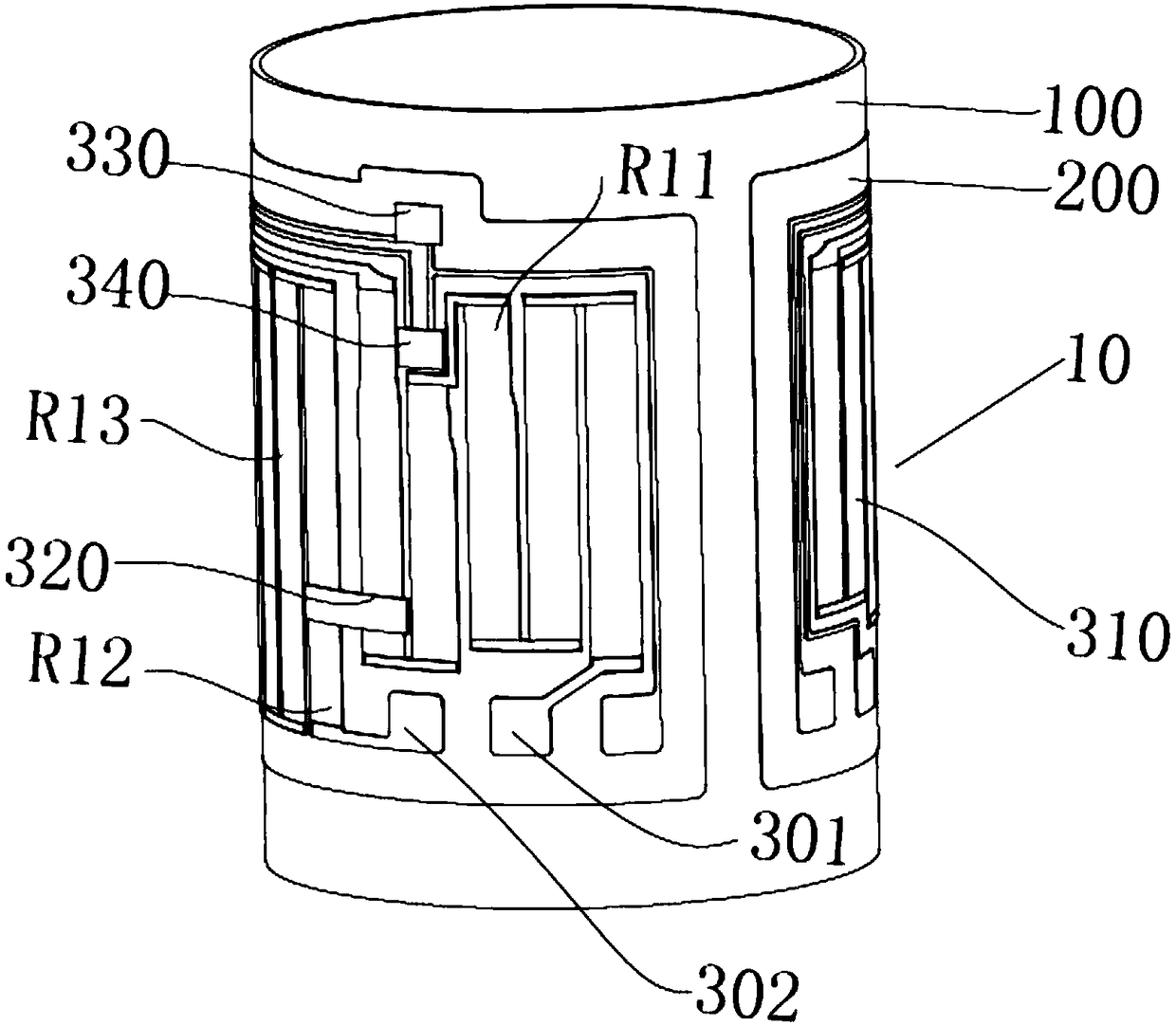

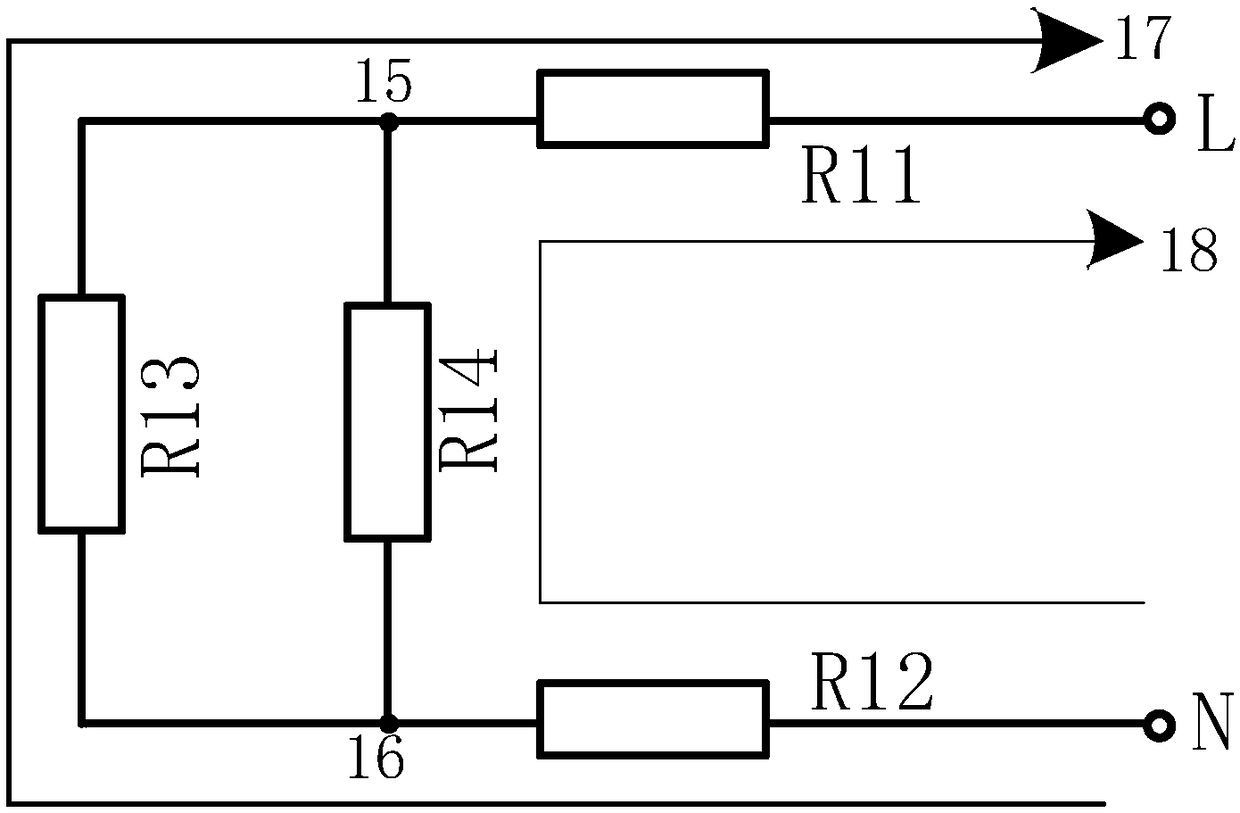

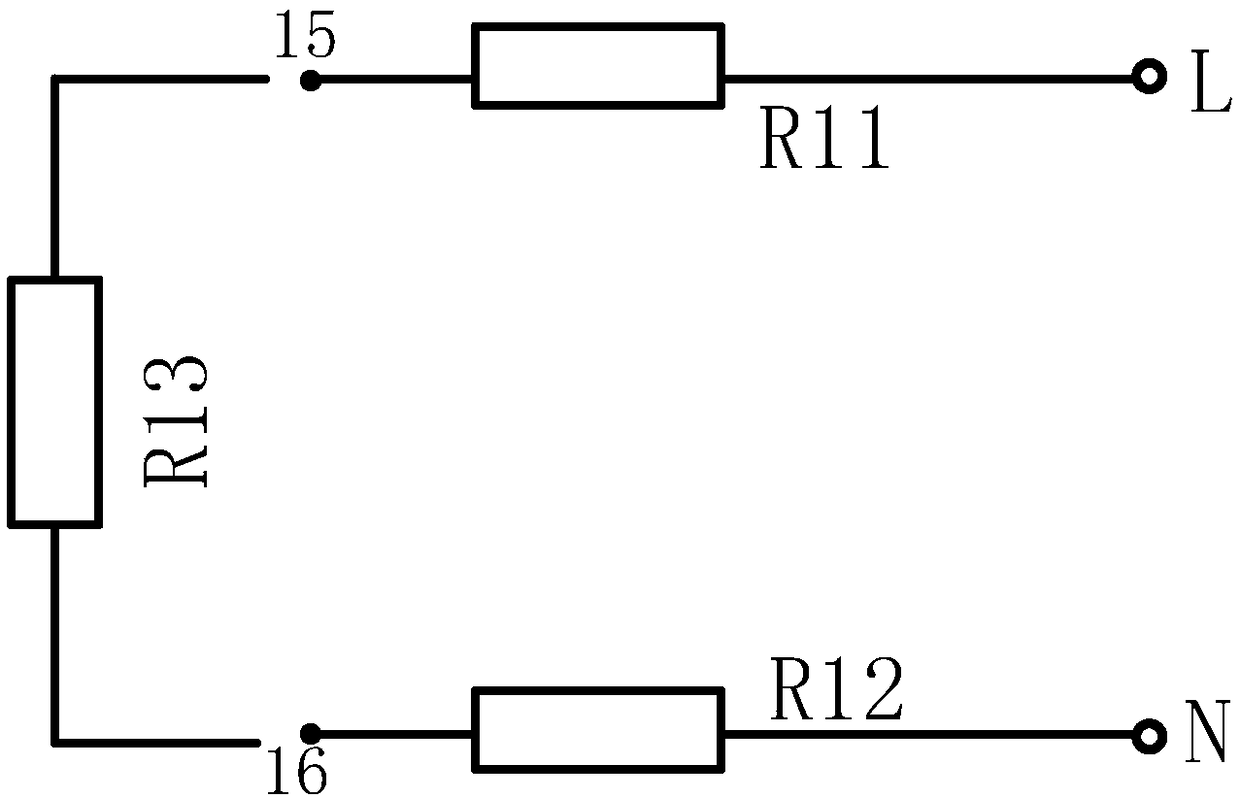

[0023] like figure 1 As shown, the embodiment of the present invention provides a heater 10, including a metal base layer 100, an insulating dielectric layer 200 printed on the metal base layer 100, a first electrode 301 printed and burned on the insulating dielectric layer 200, and a second The second electrode 302 is a heating resistor printed on the insulating medium layer 200. The heating resistor 310 includes a first connection terminal R11 and a second connection terminal R12 and R13, wherein the first connection terminal R11 is connected to the first electrode 301, and the second connection terminal R12 Connect the second electrode 302, and also include a thermal fuse 320 printed and burned on the insulating medium layer 200, one end of the thermal fuse 320 spans the heating resistor R11 at the first connection end, and the other end of the thermal fuse 320 spans the heating resistor at the second connection end R12.

[0024] In the heater provided by the embodiment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com