Orthopedic surgery steel wire twisting device

An orthopedic surgery and wire technology, applied in the field of medical devices, can solve the problems of labor and inconvenience in operation, and achieve the effects of simple structure, convenient operation and easy mastery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

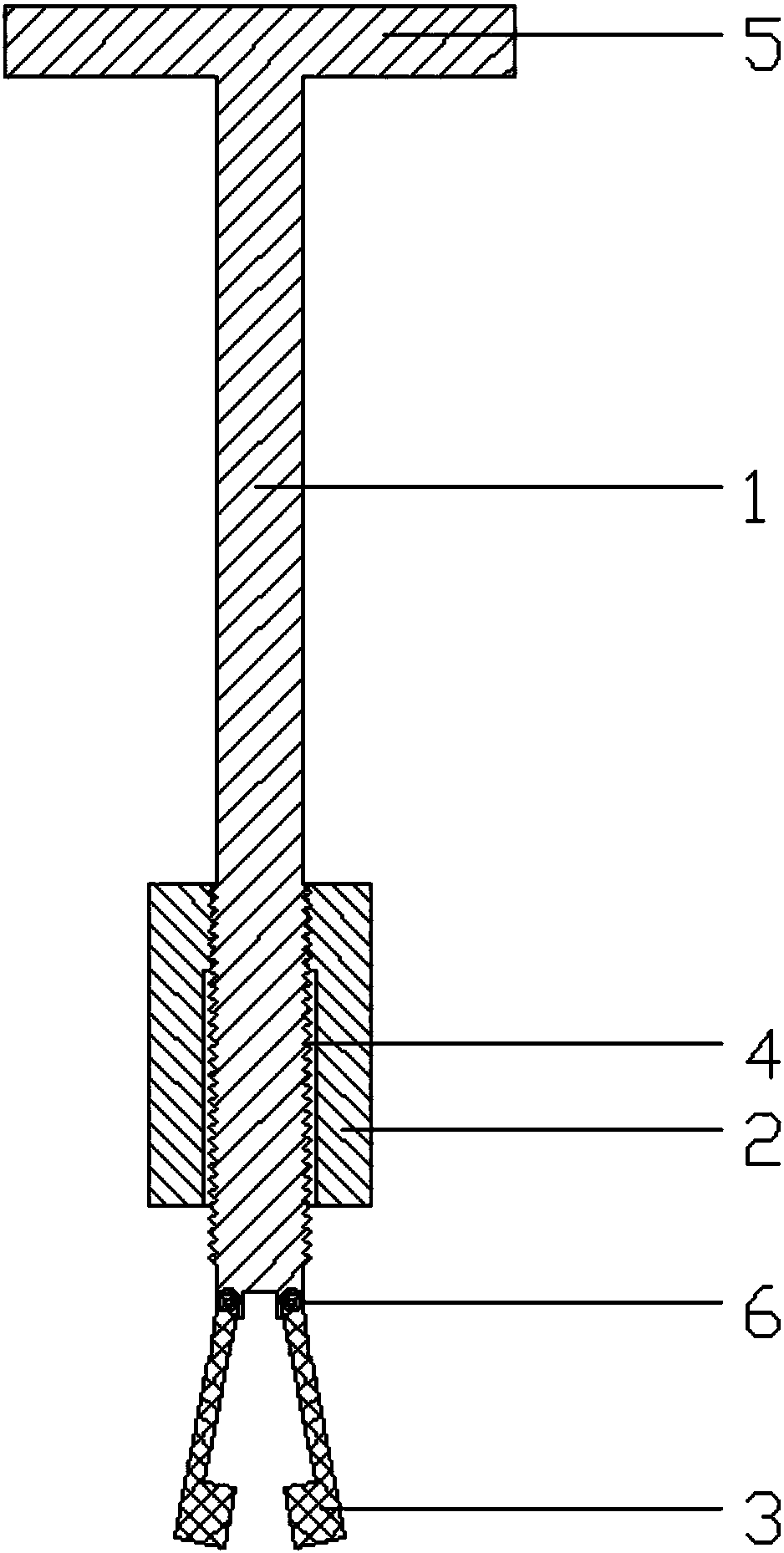

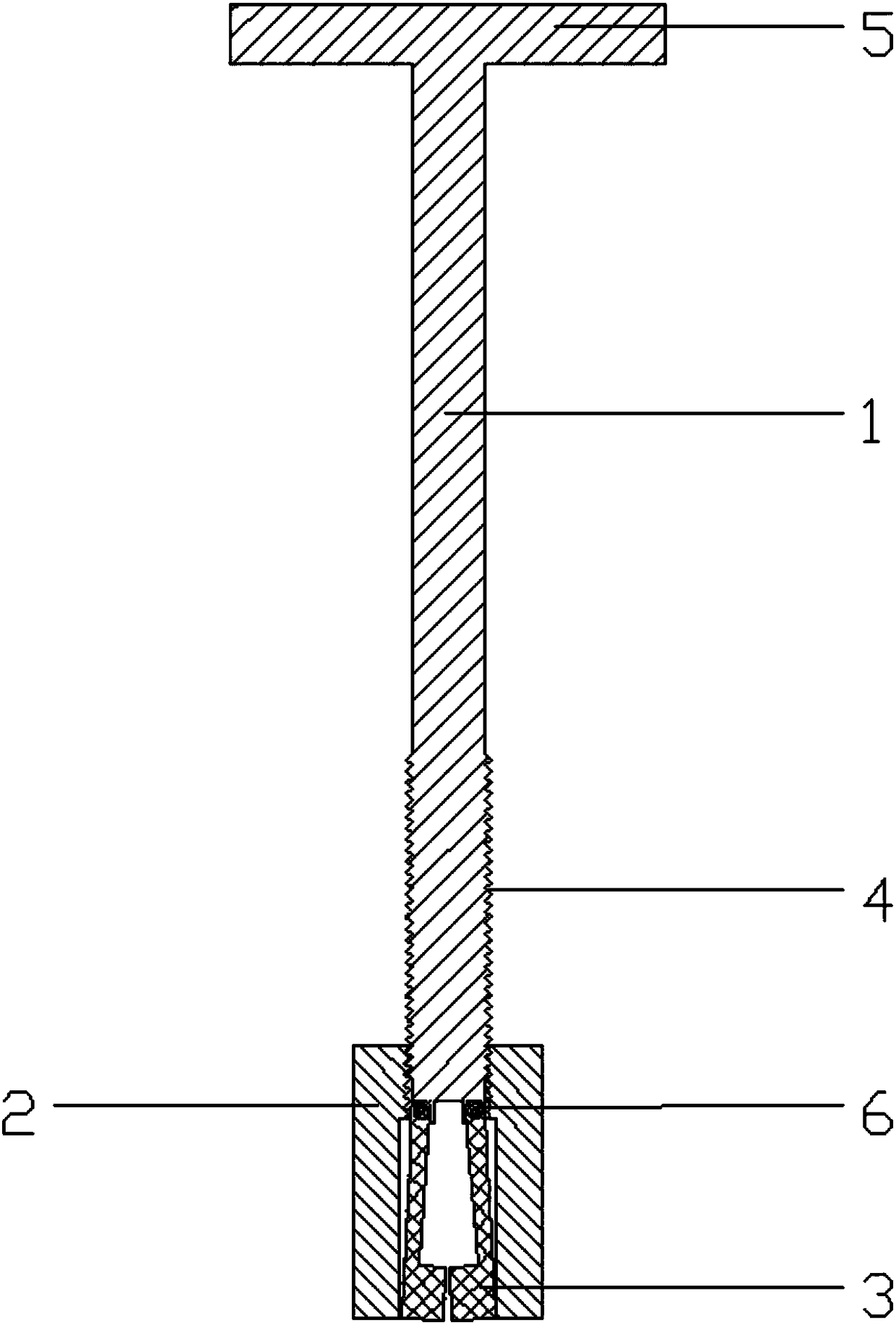

[0028] like figure 1 As shown, the orthopedic surgery steel wire twister disclosed in this embodiment, the transmission arm 1, the sleeve 2 and the clamping device, the rear end of the transmission arm 1 is provided with a handle 5, the front end of the transmission arm 1 is provided with a clamping device, and the clamping device A three-lobe occluder in the prior art can be selected. In this embodiment, the clamping device includes three clamping arms 3, and the three clamping arms 3 are opened under the action of elastic force; the sleeve 2 is set on the transmission arm 1, and the transmission arm 1 is provided with an external thread 4, and the external thread 4 extends To the front end of the transmission arm 1, the rear part of the sleeve 2 has an internal thread adapted to the external thread 4. The sleeve 2 is threadedly matched with the transmission arm 1 .

[0029] The front part of the sleeve 2 is in clearance fit with the transmission arm 1, and the three clampi...

Embodiment 2

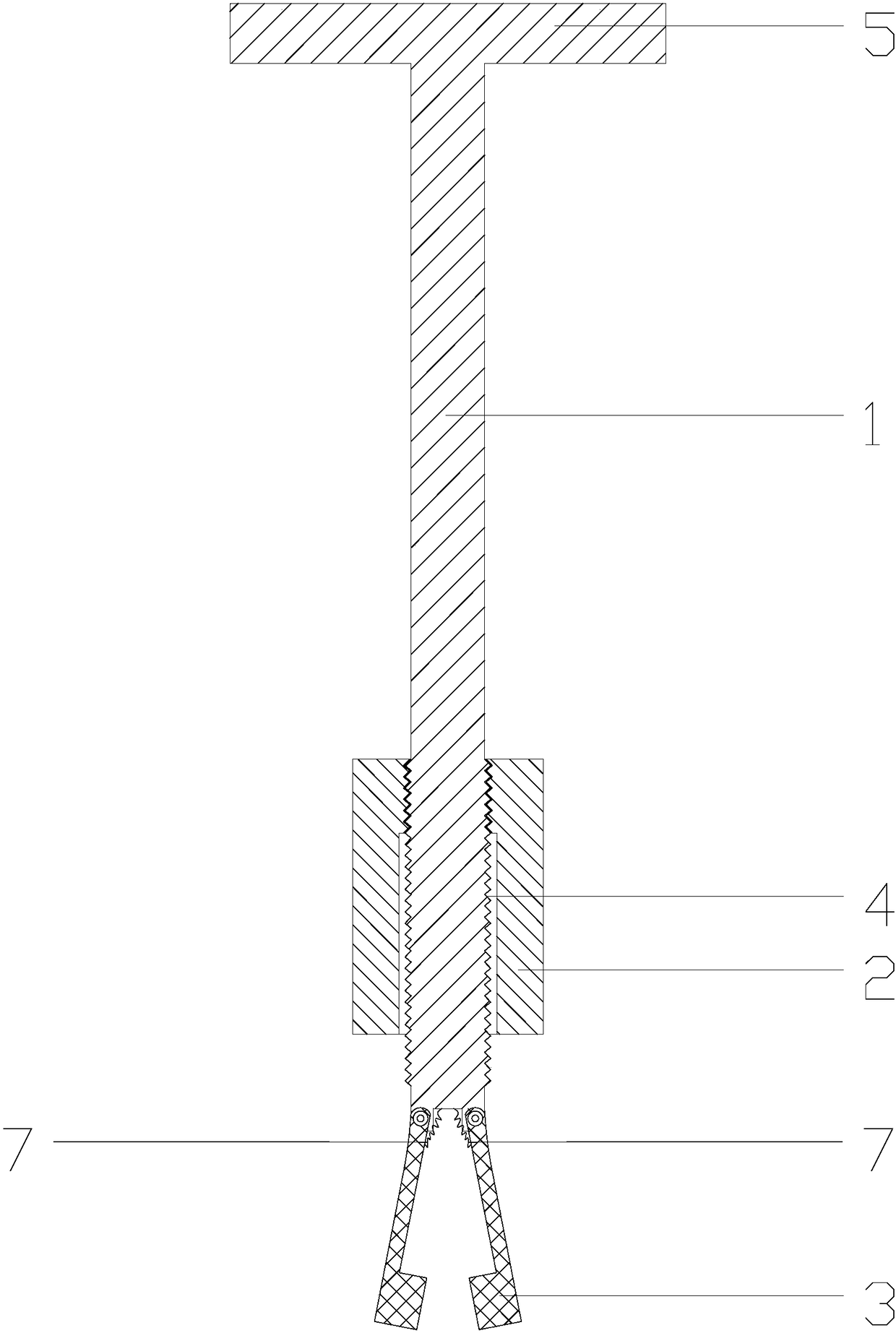

[0033] The difference between this embodiment and embodiment 1 is: as image 3 As shown, the elastic force to open the clip arm 3 is provided by the coil spring 7 . One end of clamp arm 3 is hinged with transmission arm 1 , one end of coil spring 7 is connected with clamp arm 3 , the other end of coil spring 7 is connected with transmission arm 1 , and coil spring 7 is located inside clamp arm 3 .

Embodiment 3

[0035] The difference between this embodiment and embodiment 1 is: as Figure 4 As shown, the elastic force to open the clamp arm 3 is provided by the clamp arm 3 itself. The clamping arm 3 is an elastic piece, and one end of the clamping arm 3 is fixedly connected to the transmission arm 1, and can be fixed by screws or welding. Three clamp arms 3 can be manufactured in one piece.

[0036] like Figure 5 As shown, the sleeve 2 is rotated to move forward along the transmission arm 1, and the sleeve 2 gradually presses the clamping arm 3 inward until the clamping device is clamped. Because the sleeve 2 is threadedly matched with the transmission arm 1, the clamping device can be kept in a clamped state, and the tail end of the steel wire can be firmly clamped. Subsequently, the handle 5 of the rotation T can twist the steel wire or remove the steel wire. Finally, reversely rotate the sleeve 2 so that it moves backward along the transmission arm 1. Breaking away from the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com