Intelligent logistics cart

An intelligent logistics and trolley technology, applied in vehicle position/route/height control, non-electric variable control, instruments, etc., can solve the problems of inability to consolidate autonomous time, low handling efficiency, and few mechanical products, so as to improve an intelligent , strong marketability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

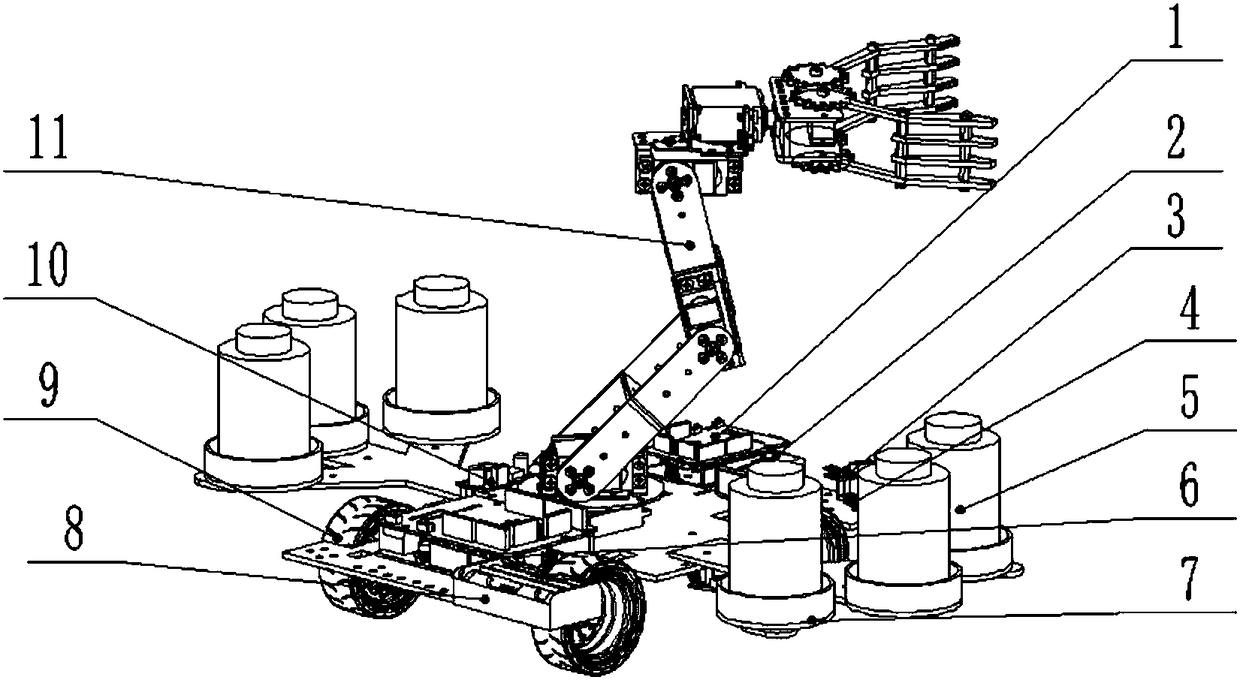

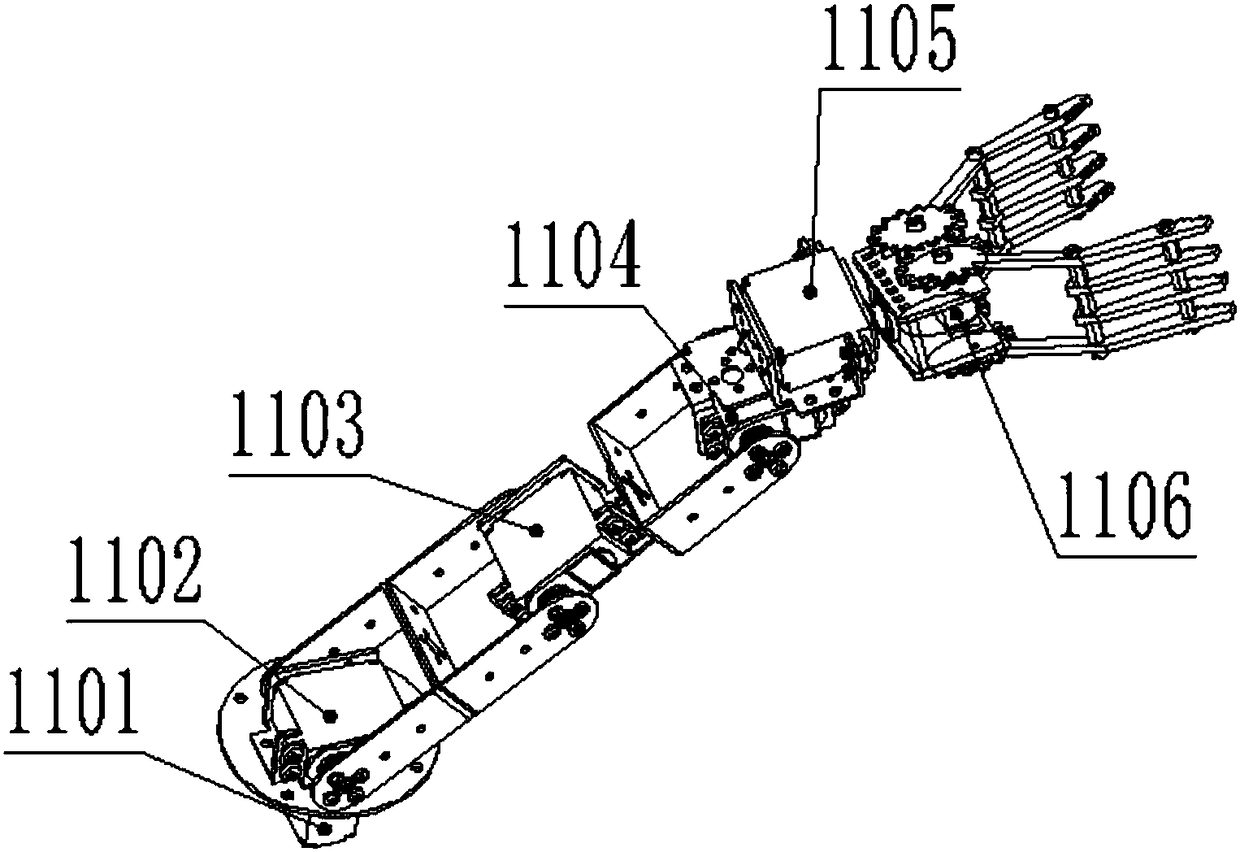

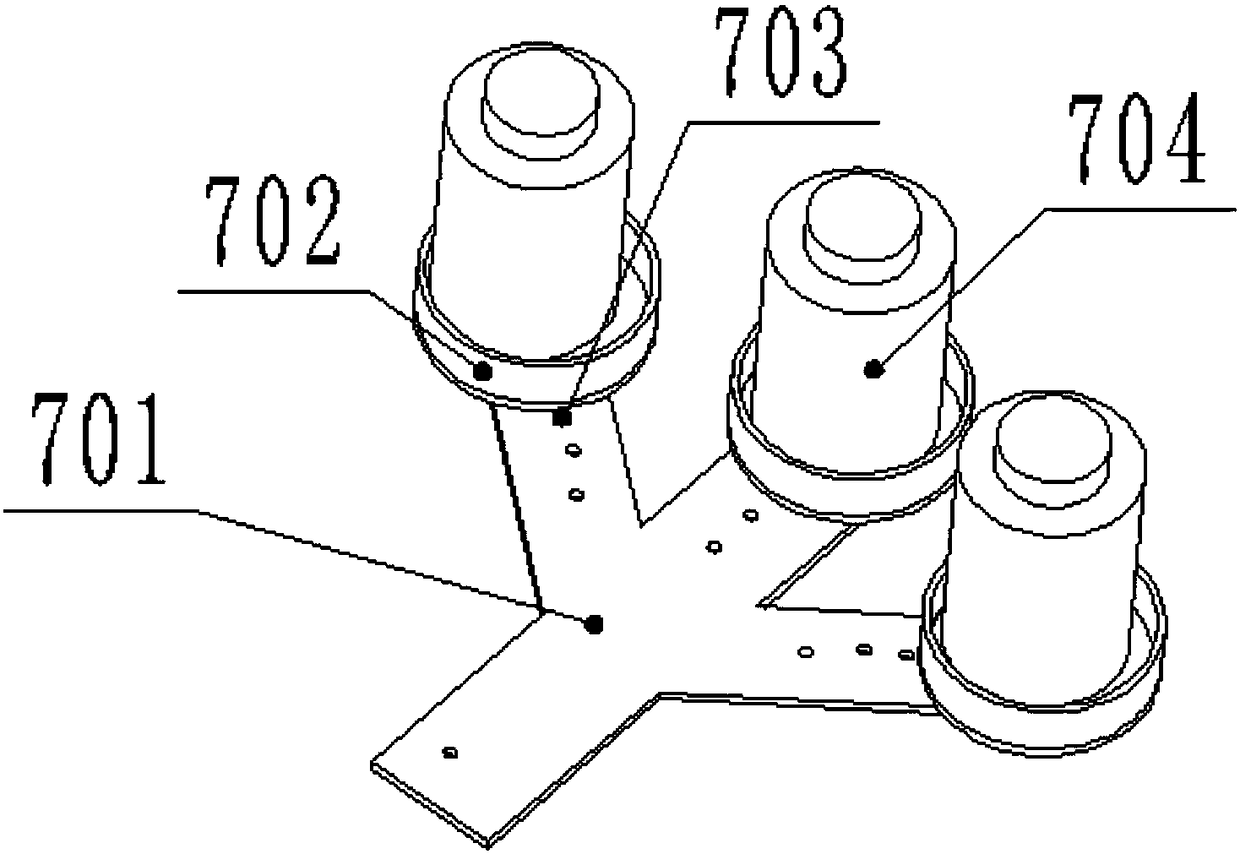

[0022] The intelligent logistics trolley of the present invention comprises a car body and wheels 6 arranged under the car body. The trolley is provided with a motor for driving the wheels 6, a wheel steering gear for changing the direction of the wheels, a steering gear power supply battery 2, a central controller 1, a central The controller feeds the steering signal to the wheel steering gear, which is characterized in that: the front end of the car body is provided with an obstacle avoidance module 3 and a tracking module 4, and the infrared detection device on the obstacle avoidance module 3 measures the distance of the obstacle ahead and transmits the measurement data To the central controller 1, the tracking module 4 detects the navigation black line on the floor and inputs the distance data between the current vehicle body and the naviga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com