Concrete mixing method based on full-automatic concrete mixing equipment

A technology of mixing equipment and mixing method, which is applied to clay preparation devices, cement mixing devices, chemical instruments and methods, etc., can solve the problems of uneven quality of manual mixing, low space requirements, and low production efficiency, and achieves good results. The effect of computer interaction performance, labor intensity reduction, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

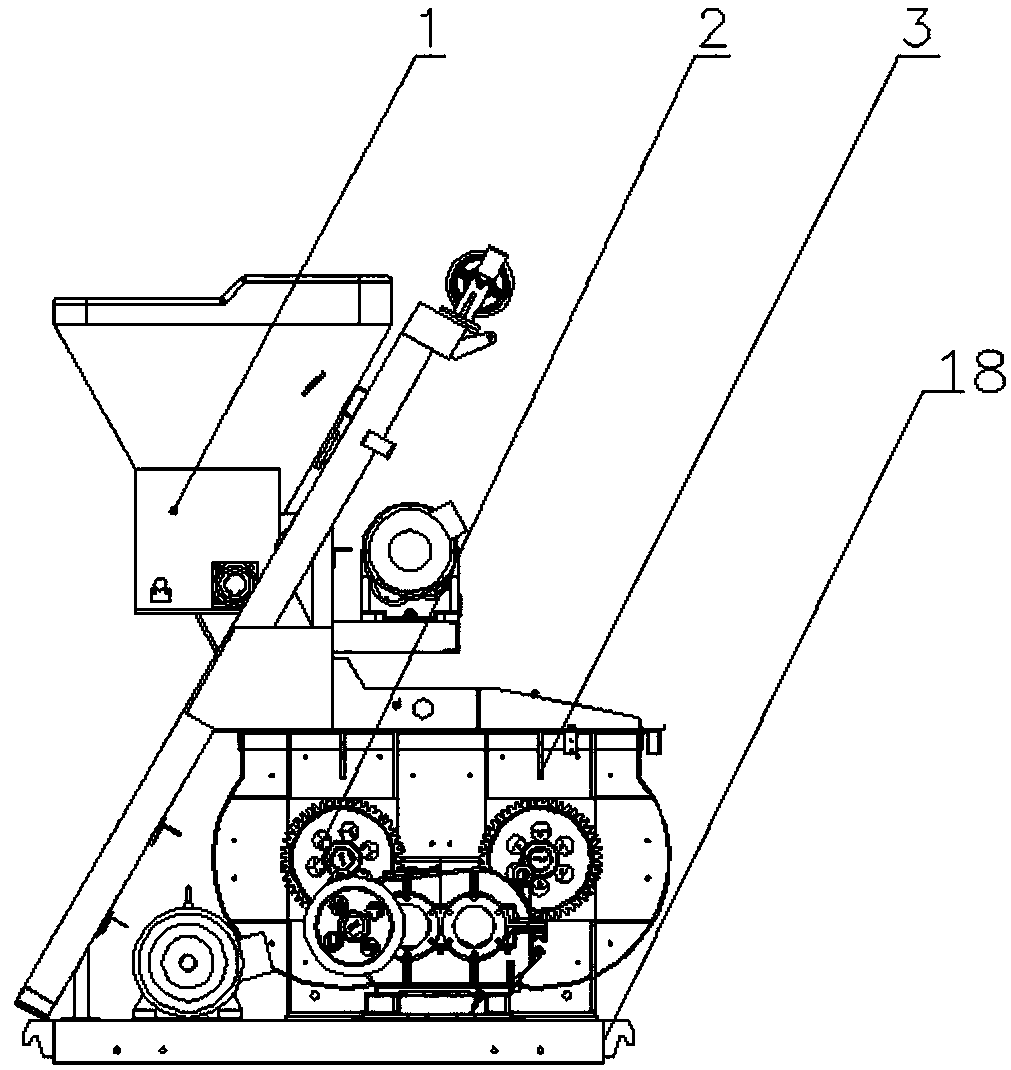

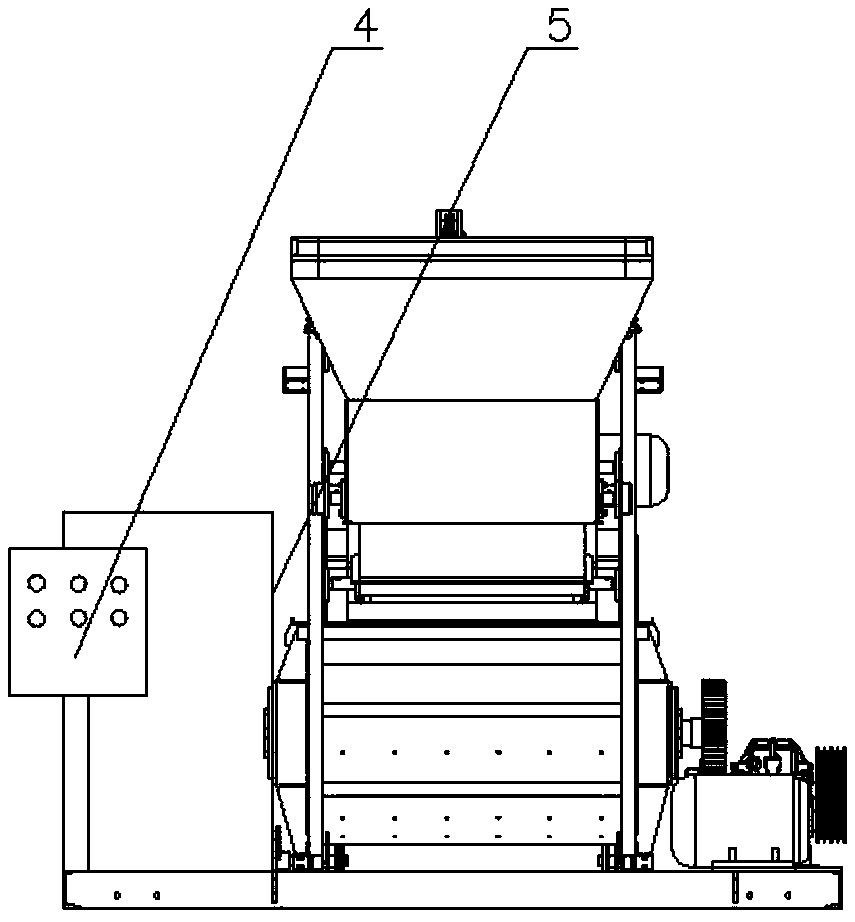

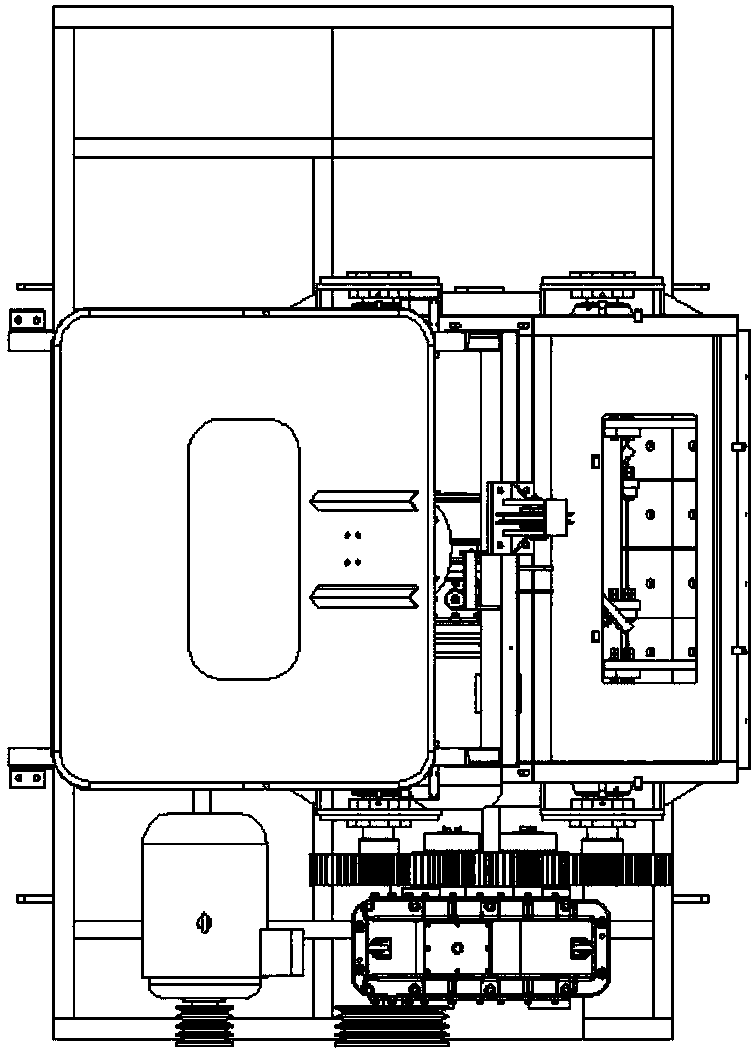

[0090] Such as Figure 1-3 As shown, the fully automatic concrete mixing equipment includes a base 18, a feeding mechanism 1, a transmission mechanism 2, a stirring mechanism 3, an operation panel 4 and an electrical cabinet 5; the operation panel 4 includes various buttons and display devices, so The above buttons include a start button and an emergency stop button; the operator can input various data according to the display device, and operate according to the prompts of the display device; press the start button when starting, and press the stop button when stopping, after the operator completes input data , press the start button, the machine operates; various electrical components are installed in the electrical cabinet 5, the equipment is controlled by PLC, and the control panel buttons are manually operated.

[0091] Such as Figure 4-11 As shown, the feeding mechanism 1 includes a track support 11 and a hopper 6, and the two sides of the hopper 6 are respectively fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com