Air bubble film full-automatic winding device

A technology of winding device and air bubble film, which is applied in the directions of winding strips, transportation and packaging, and thin material processing, etc., which can solve problems such as troublesome operation, long time to remove the air bubble film, and increased labor intensity of workers, so as to speed up the production process. The effect of production speed, reduction of production cost and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the drawings:

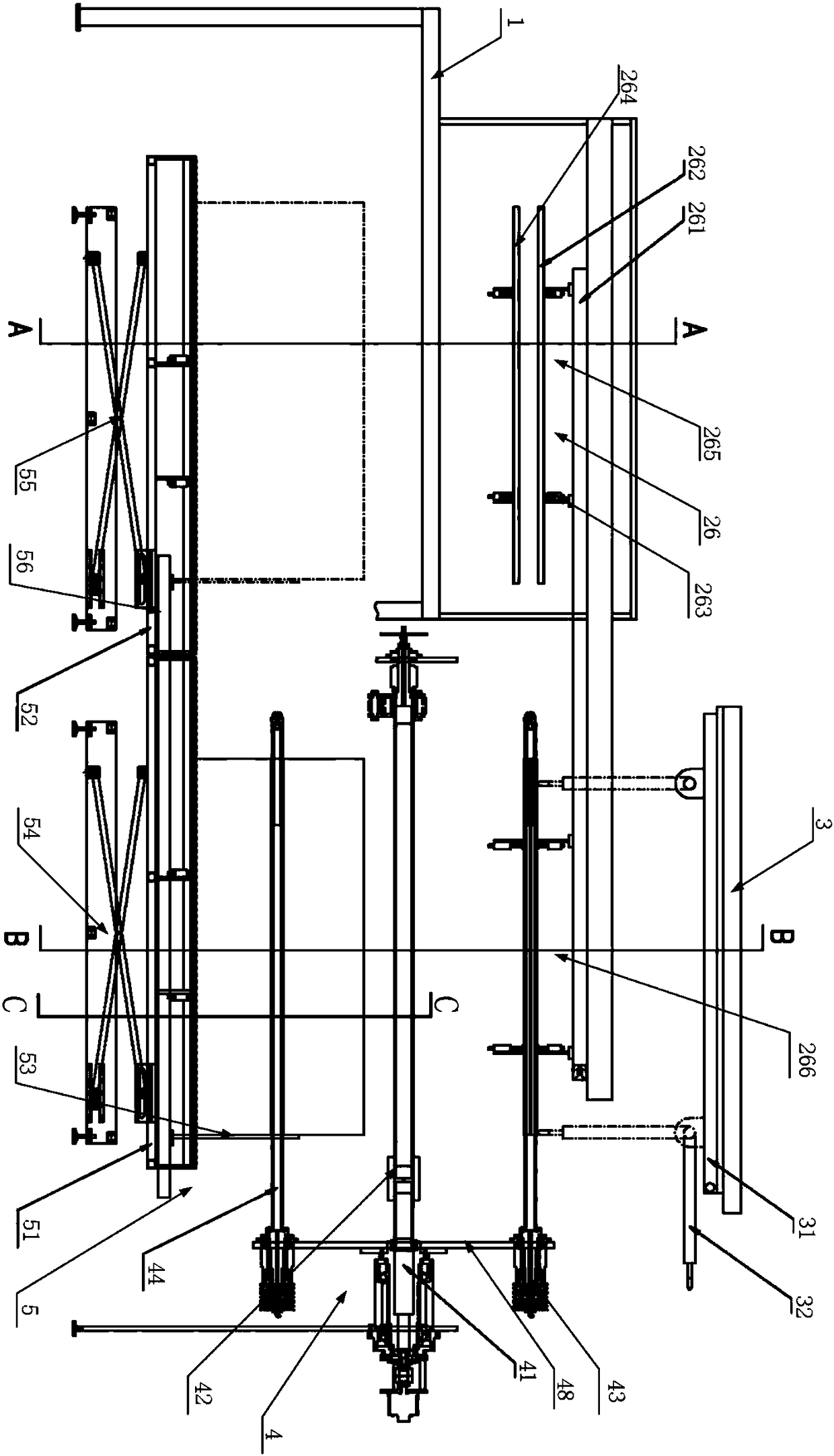

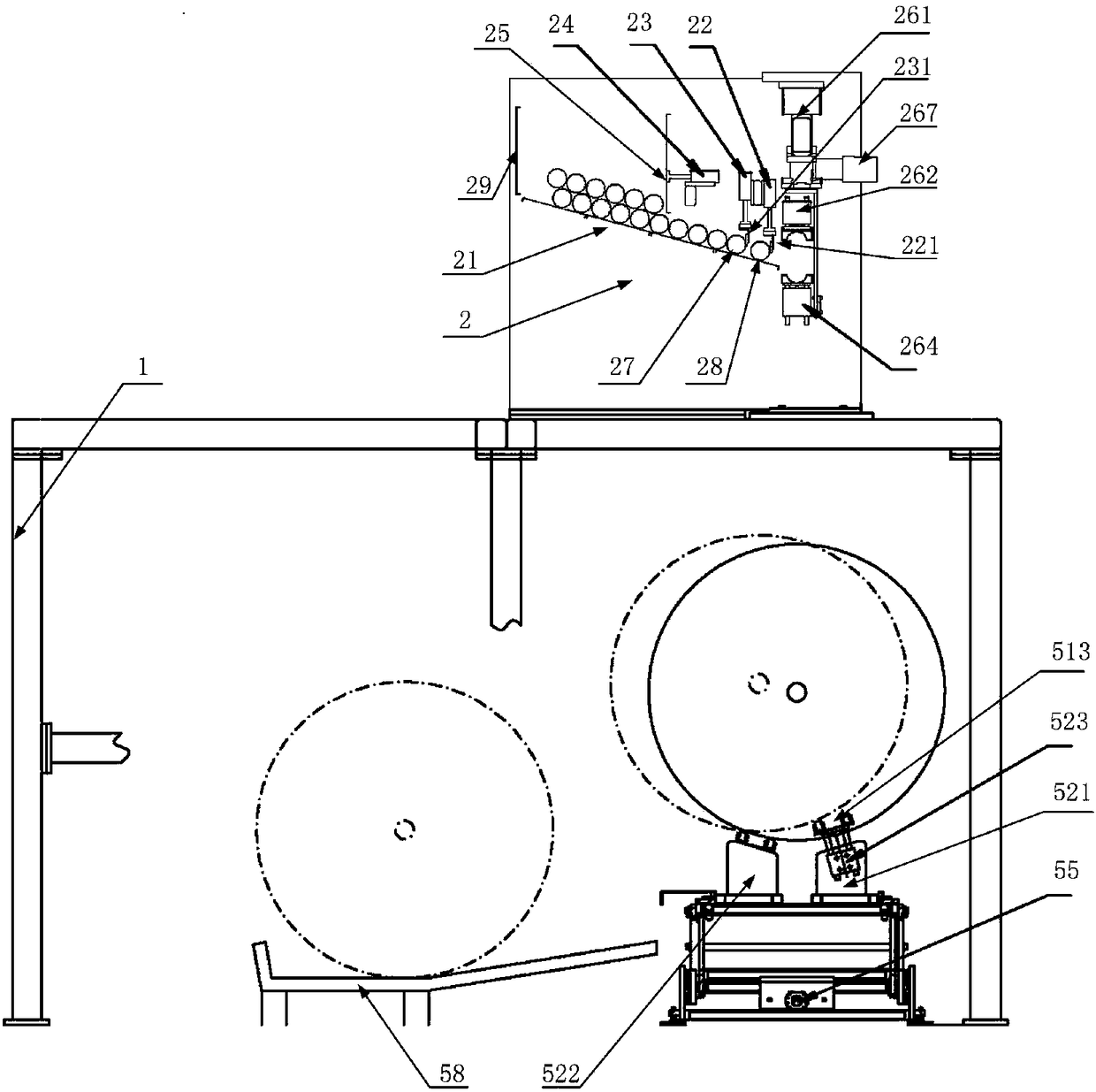

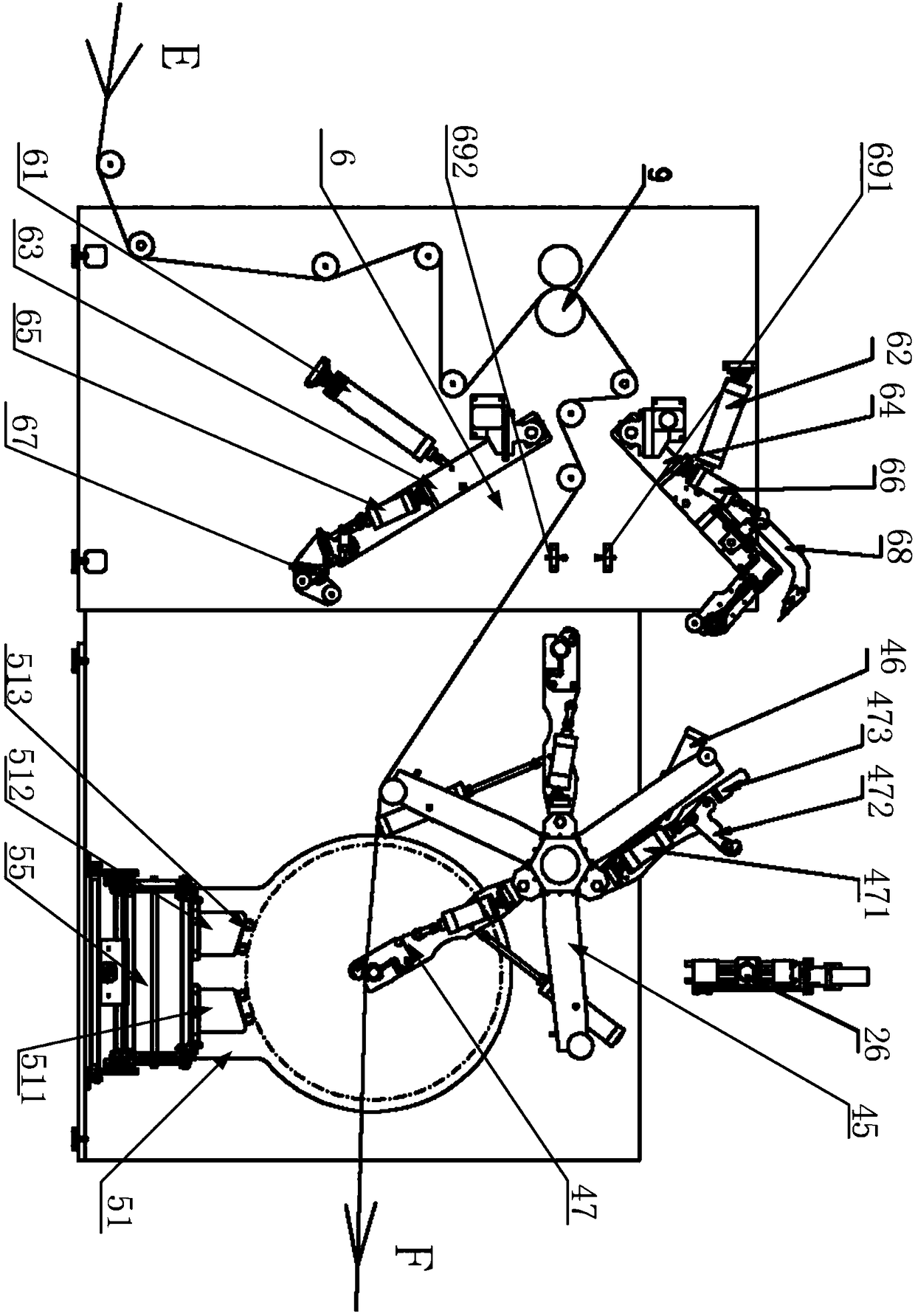

[0026] Please attach Figure 1-5 As shown, a fully automatic air bubble film winding device includes a roll storage device 2, a gluing device 3, a roll-up clamping device 4, a cutting device 6, a discharging device 5, and a multiple Roller group 9 for transporting bubble film consisting of two rollers.

[0027] Please continue to refer to the attached figure 1 with 2 As shown, the reel storage device 2 includes a loading inclined plate 21, an eighth cylinder 24, and a collet mechanism 26. The upper end of the loading inclined plate 21 is provided with a fixed baffle 29, and the output end of the eighth cylinder 24 is provided with a flexible The baffle 25 drives the flexible baffle 25 to move. The flexible baffle 25 and the fixed baffle 29 form a space for storing the roll. The flexible baffle 25 can move the roll to keep the roll tidy. The lower end of the feeding swash plate 21 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com