Preparation method of zno/ag nano hybrid electron transport film obtained by electrospinning

An electrospinning method and electron transmission technology, applied in nanotechnology, nanotechnology, semiconductor/solid-state device manufacturing, etc., can solve the problems of complex equipment, low production efficiency, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation of the ZnO-Ag nano electron transport thin film includes step 1 and step 2.

[0039] Step 1, the preparation of Ag nanowires, including the following sub-steps:

[0040] Step 1.1, take 0.25g of PVP and add it to 6ml of ethylene glycol and stir until dissolved to obtain a PVP solution;

[0041] Step 1.2, take 0.1g of AgNO 3 Add to the same amount of ethylene glycol solution as above and stir until dissolved to obtain AgNO 3 solution;

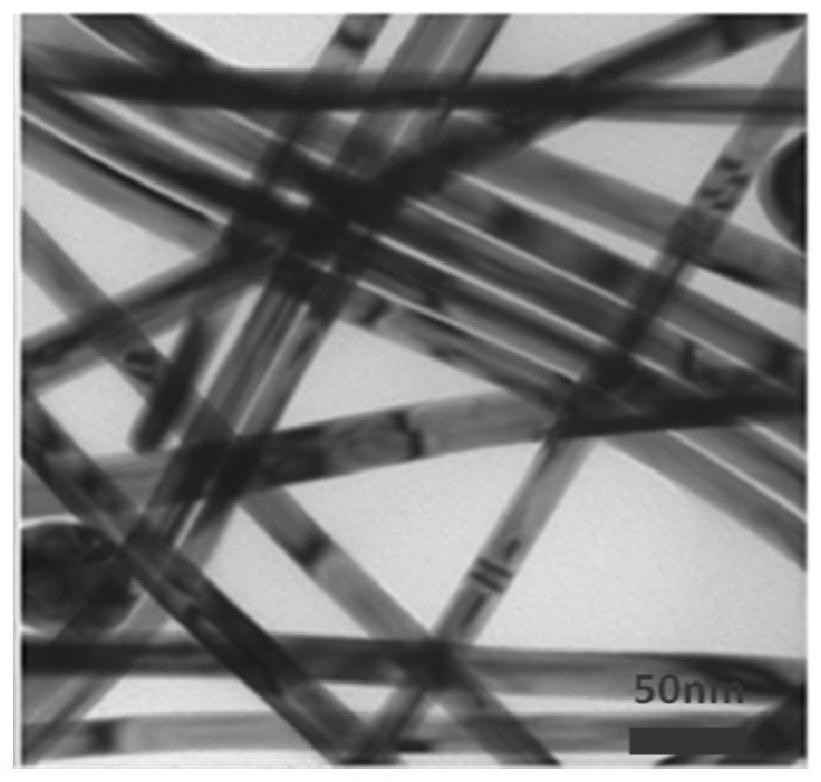

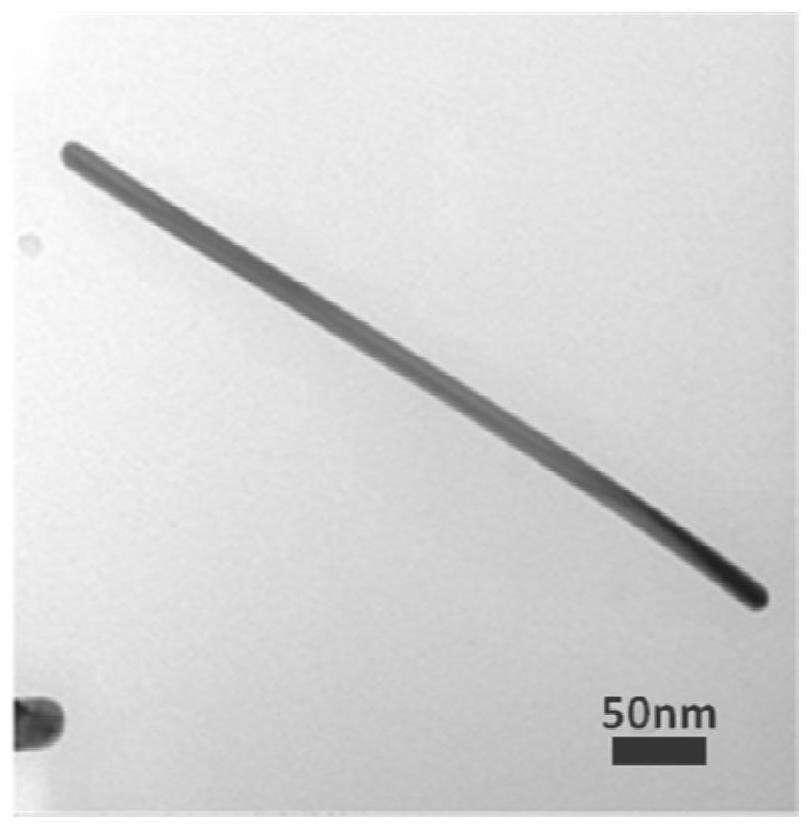

[0042] Step 1.3, Preheat the PVP solution at 170°C for 1 hour, then take the above AgNO 3 The solution was added into the PVP solution at a rate of 6 mL / min, and the reaction was continued for 10 min; the Ag nanowire sol was obtained after the reaction was completed. The obtained Ag nanostructures are as diagram 2-1 with Figure 2-2 As shown, it can be seen that the width of the silver nanowires is about 20 nanometers.

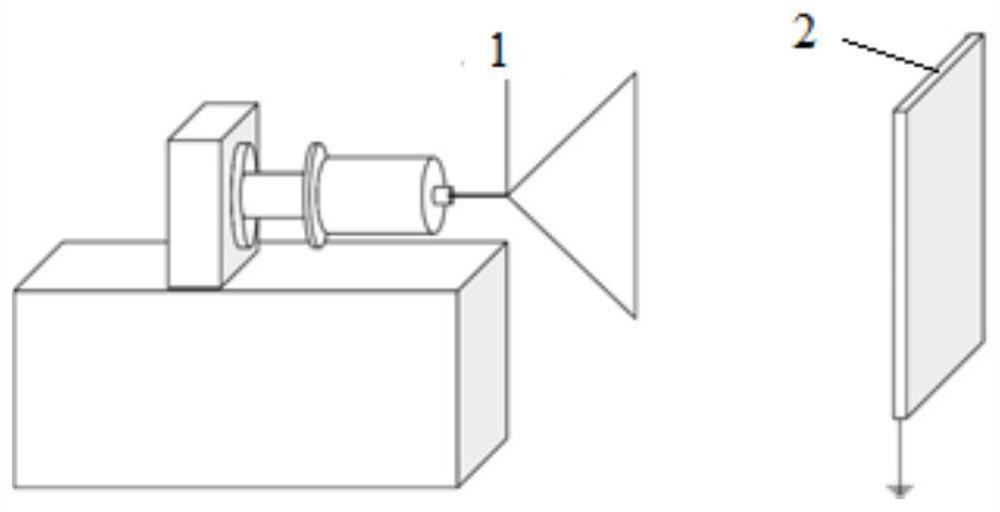

[0043] Step 2, using the electrospinning method to prepare ZnO / Ag nano-hybrid electron transport...

Embodiment 2

[0049] In addition to the AgNO in step 1.2 3 Except that the addition amount of ZnO-Ag nano-hybrid electron transport film was prepared by the same method as in Example 1 except that the addition amount was changed to 0.2 parts by weight.

Embodiment 3

[0051] In addition to the AgNO in step 1.2 3 Except that the addition amount of ZnO-Ag nano-hybrid electron transport film was prepared by the same method as in Example 1 except that the addition amount was changed to 0.14 parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com