Bolt splicing axis bendable all-prefabricated splicing open excavated cable tunnel

A prefabricated assembly and cable tunnel technology, which is used in cable installation, cable installation in tunnels, water conservancy projects, etc. Insufficient wall flatness and other problems to achieve the effect of improving connection quality, reducing on-site workload and short operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Best practice:

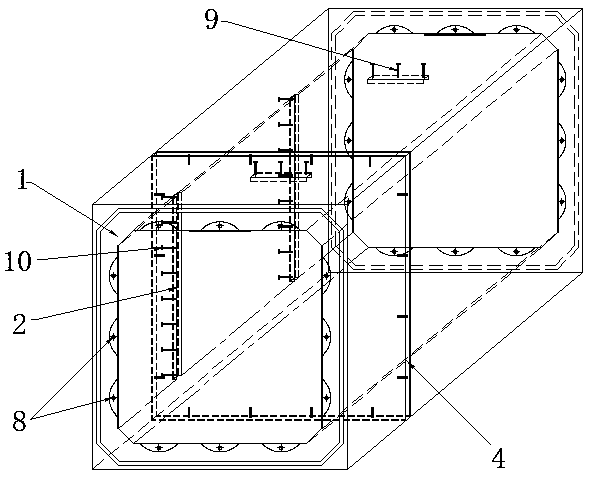

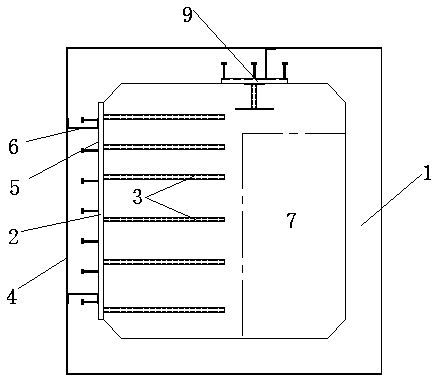

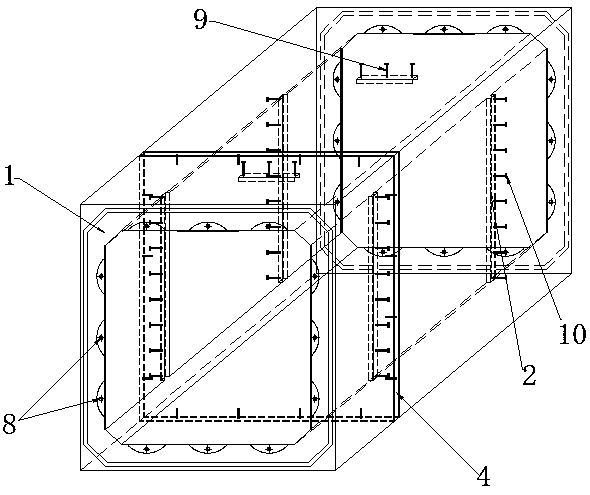

[0027] The fully prefabricated assembled open-cut cable tunnel with bolt splicing axis is bendable, which is composed of multiple sections of cable prefabricated tunnels, including standard section tunnels and curved section tunnels, and each section of cable prefabricated tunnel includes a return type tunnel body 1. Grounding system and a support system; the back-shaped tunnel body 1 includes a bottom plate, a top plate and two side walls, and the cross section is a back-shaped structure; the back-shaped tunnel body includes a cable erection space and a pedestrian maintenance passage formed by a cantilever cross bracket; the following Further elaboration according to the spatial arrangement in the tunnel body:

[0028] Refer to attached figure 1 , 2 , 5. Fully prefabricated assembled open-cut cable tunnel arranged on one side. The support system includes a trough member 2 and a cantilever cross support 3. The trough member 2 is pre-embedded in one si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com