Self-heating phase-change storage unit and self-heating phase-change storage structure

A phase-change storage and self-heating technology, applied in electrical components and other directions, can solve the problems of high power consumption of phase-change memory, easy thermal interference of phase-change memory cells, etc., to avoid thermal interference, low power consumption, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

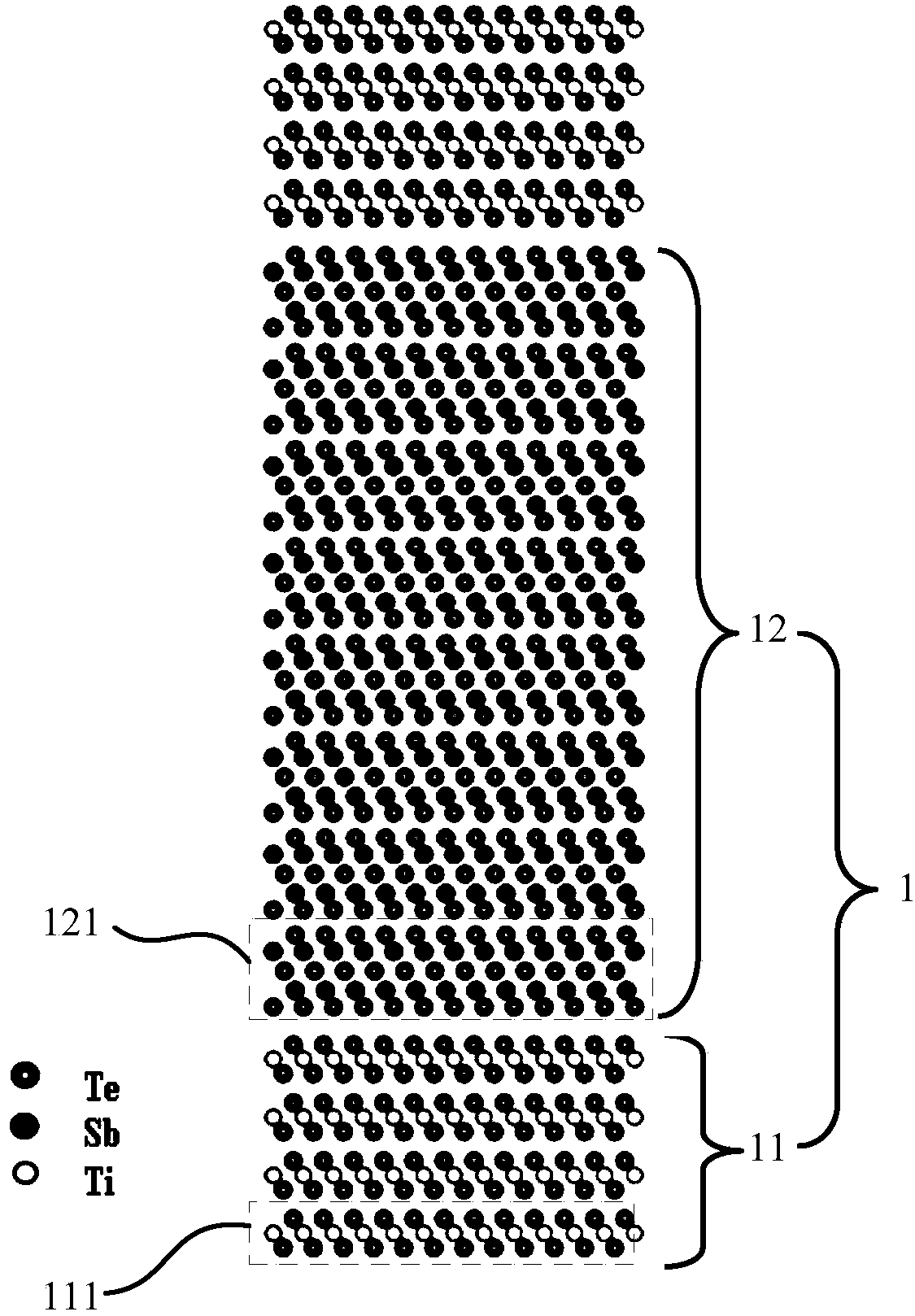

[0044] like Figure 7 As shown, the present invention also provides a self-heating phase-change memory structure, the self-heating phase-change memory structure includes at least one stacked structure, and the stacked structure includes at least one self-heating phase as described in Embodiment 1 Change storage unit 1. In order to expand the storage capacity of the self-heating phase-change memory structure, the stacked structure usually includes a plurality of self-heating phase-change memory cells 1 stacked in sequence, wherein one of the self-heating phase-change memory cells 1 The phase-change storage medium 12 is in contact with the self-heating electrode 11 in another self-heating phase-change storage unit 1 adjacent thereto. In this embodiment, the self-heating phase-change memory structure includes two stacked structures, and the two stacked structures are arranged side by side and are provided with an isolation material, such as an insulating material, between them. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com