Mordenite zeolite catalyst with special morphology and preparation method thereof

A mordenite and catalyst technology, applied in the field of special morphology mordenite catalyst and its preparation, can solve problems such as poor diffusion performance of molecular sieve catalyst, and achieve the effects of excellent reaction performance, improved performance, and smooth diffusion channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

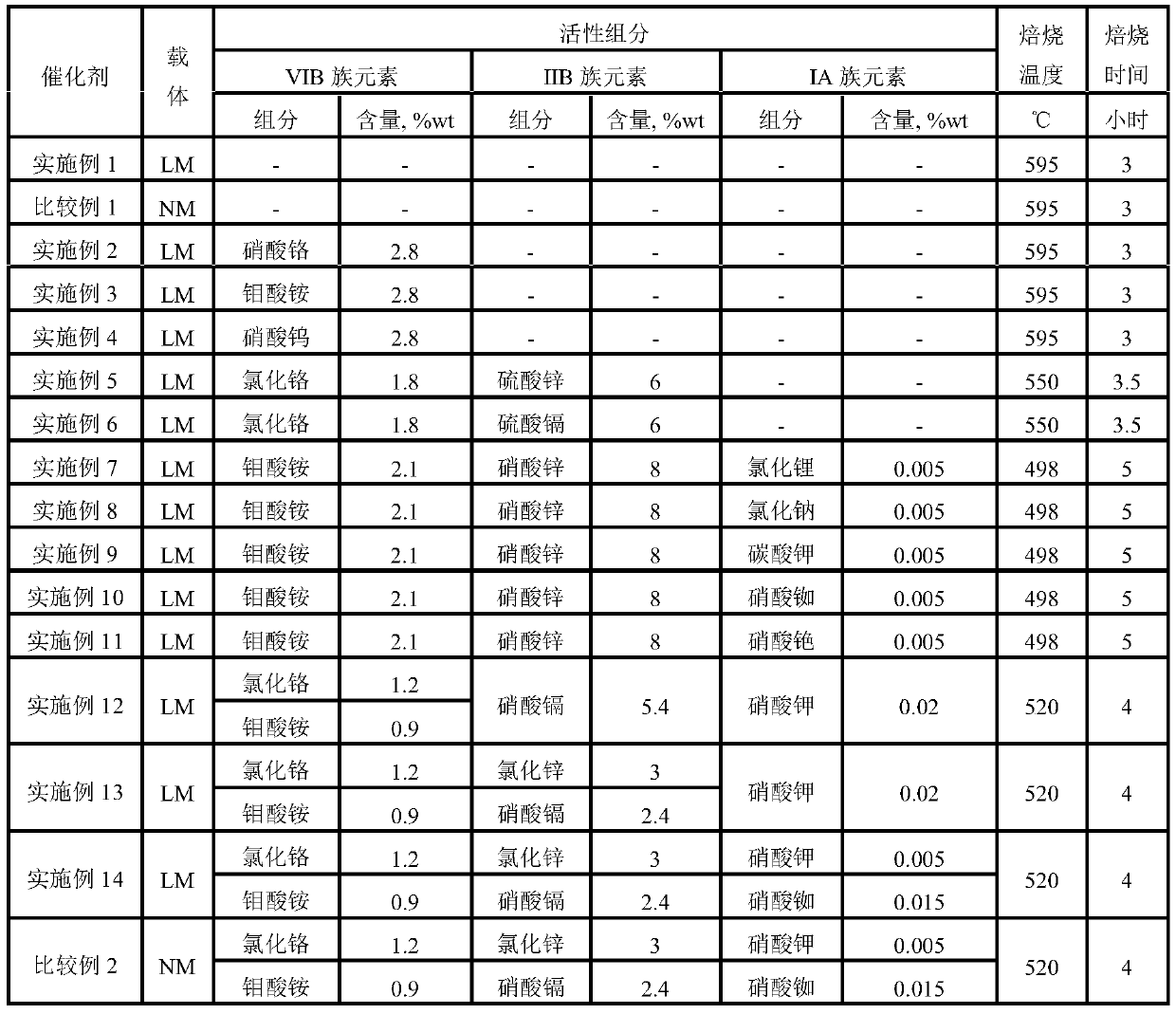

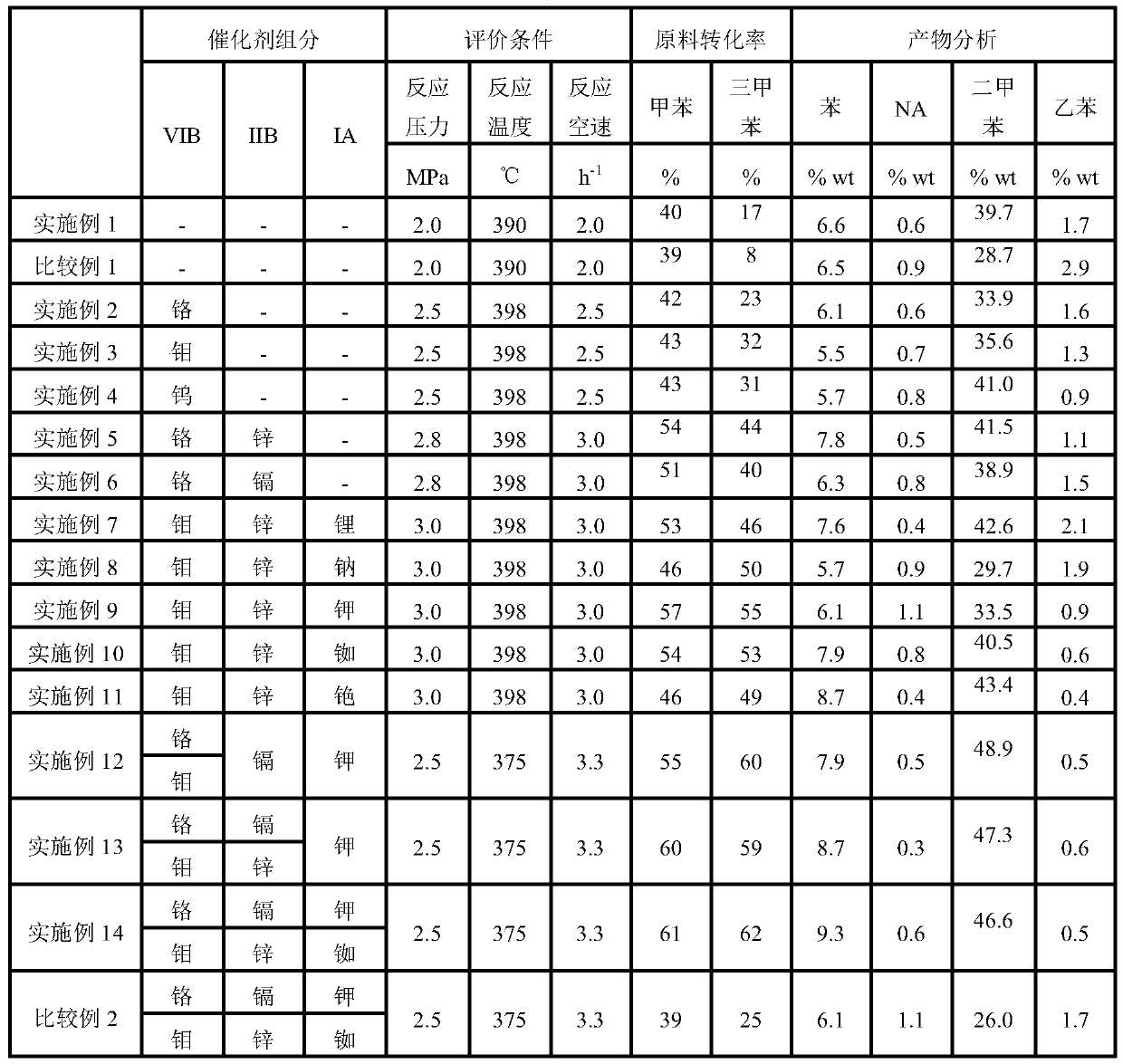

Embodiment 1

[0033] Weigh 60 grams of chain-shaped mordenite (referred to as LM, with a silicon-aluminum ratio of 25), add deionized water and knead evenly, extrude into a rod, and dry to obtain a catalyst precursor. The precursor is calcined at 595 ° C for 3 hours in an air atmosphere , pelletized to obtain the catalyst.

[0034] With the above-mentioned catalyst, the catalyst evaluation was carried out on a fixed-bed continuous micro-reactor near hydrogen, and the reactor specification was The loading capacity is 20.0 grams. The aromatic hydrocarbon transalkylation reaction uses toluene and trimethylbenzene with a molar ratio of 45:55 as the model raw material, and the hydrogen hydrocarbon molar ratio H 2 / HC=2.7 (The following examples and comparative examples are all evaluated according to the above conditions). First use hydrogen to exhaust the air in the reaction system and pressurize it to 2.0MPa, and control the feed reaction space velocity of the above raw materials to 2.0h -1,...

Embodiment 2

[0039] Take by weighing 60 grams of LM dry powder, add chromium nitrate (according to the metal content of 2.8%wt), add deionized water and knead evenly, extrude and form, and dry to obtain the catalyst precursor, the precursor is roasted at 595 ° C in air atmosphere for 3 hours, and pelletized to obtain catalyst.

[0040] With the catalyzer that above-mentioned embodiment makes, under the working conditions of referring to embodiment 1, first discharge the air of reaction system with hydrogen and pressurize to 2.5MPa, the feeding reaction space velocity of control above-mentioned raw material is 2.5h -1 , control the reaction temperature to 398°C.

Embodiment 3

[0042] Take by weighing 60 grams of LM dry powder, add ammonium molybdate (by 2.8%wt metal content), add deionized water and knead evenly, extrude and form, and dry to obtain the catalyst precursor. Get a catalyst.

[0043] With the catalyzer that above-mentioned embodiment makes, under the working conditions of referring to embodiment 1, first discharge the air of reaction system with hydrogen and pressurize to 2.5MPa, the feeding reaction space velocity of control above-mentioned raw material is 2.5h -1 , control the reaction temperature to 398°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com