Contact type coating lip structure and extrusion coating head thereof

A contact-type, lip-closing technology, which is applied to the device and coating of the surface coating liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described below in conjunction with specific cases.

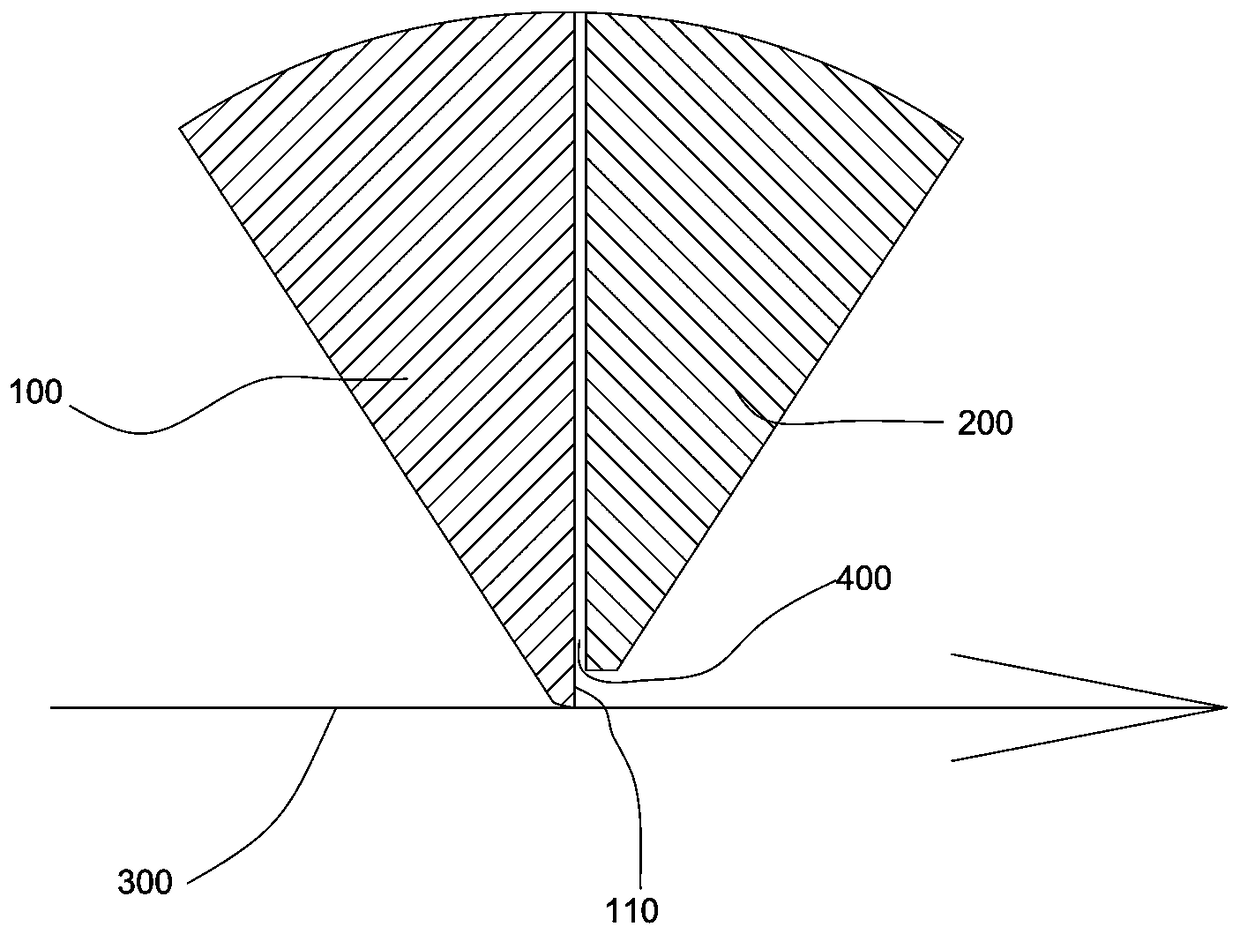

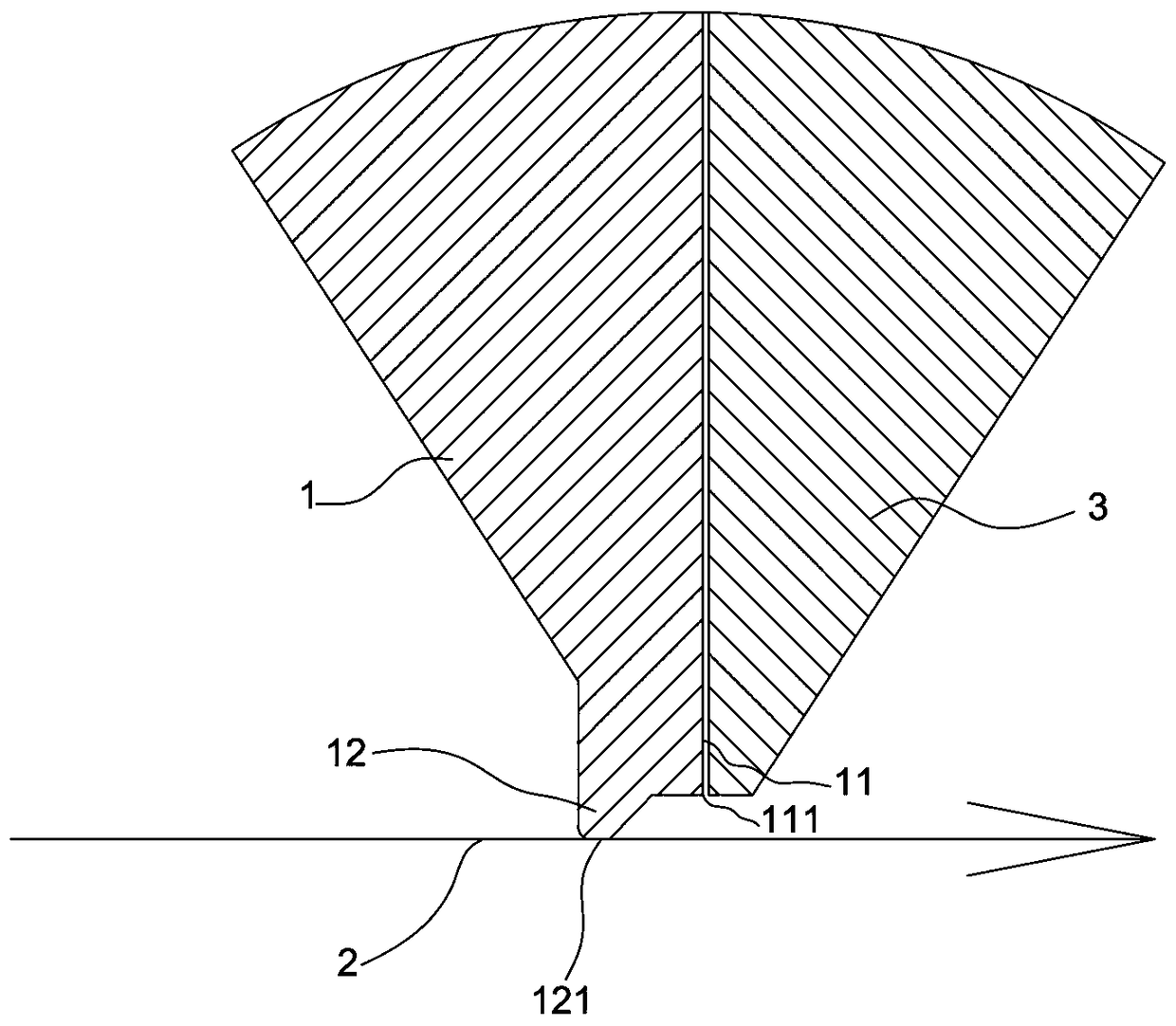

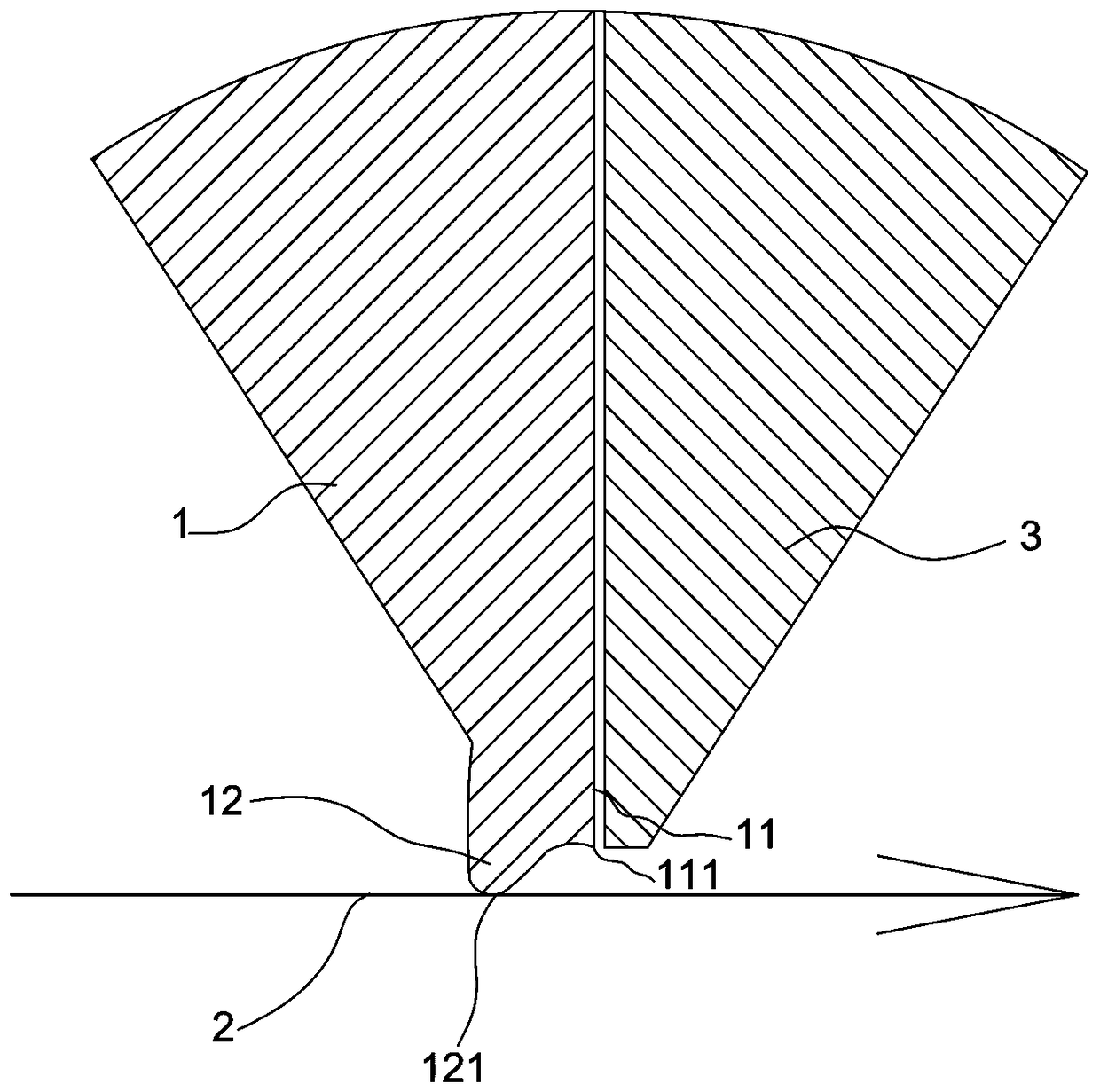

[0022] See figure 2 , figure 2 Disclosed is the first embodiment of the contact coating lip structure of the present invention; a contact coating lip structure provided in this embodiment includes a contact coating lip main body 1, and the contact coating lip main body One side of 1 is a slurry flow surface 11, and a contact portion 12 is provided on the side of the contact coating lip body 1 away from the flow surface 11, and the contact portion 12 is set as the contact portion 12 After the bottom surface 121 of the slurry is in contact with the substrate 2, the lower bottom 111 of the slurry flow surface 11 hangs above the substrate 2, so that the slurry flows out in a free state when flowing out. In this embodiment, the contact portion 12 is a bump away from the lower bottom 111 and the contact coating lip main body 1; the bottom surface 121 of the bump is a plane. The main body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com