Manufacturing equipment and manufacturing method of back-sided crossed dovetail grooves of tiles

A dovetail groove and ceramic tile technology, which is applied in the direction of manufacturing tools, ceramic molding machines, molding indenters, etc., can solve the problems of tile panel falling off, slow production speed, and large space occupation, and achieve good social and economic benefits, simple and stable structure, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

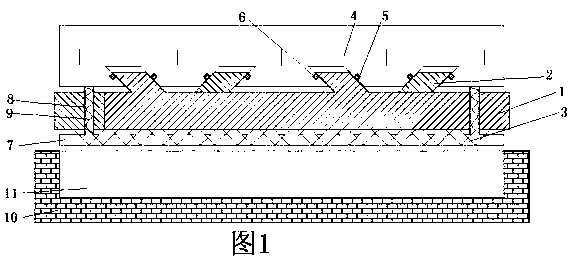

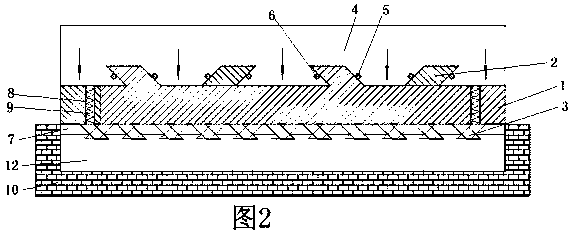

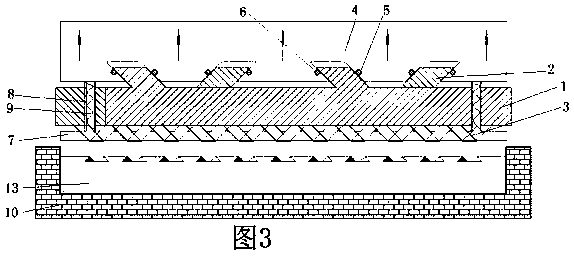

[0015] see figure 1 , a kind of manufacturing equipment and manufacturing method of the cross dovetail groove on the back of ceramic tile, it comprises hypotenuse forming sheet 1, pressing sheet driving tooth 2, embryo body forming tooth 3, back pressure bearing platen 4, the bevel edge forming sheet Driving bearing 5, retracting bearing 6 to the hypotenuse forming sheet, back pressure plate 7 of ceramic tile stamping pattern, prestressed compression fixed column 8, preloaded spring 9 in the fixed column, ceramic tile surface pressing table 10.

[0016] The specific production process: please refer to figure 1 Before the tile embryo body is loaded and pressed, the tile surface pressing table 10 is assembled with the powder material 11 before the tile embryo body is pressed, and the tile embryo body back pressing table is in the waiting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com