Diamond fret saw cutting equipment

A technology of diamond wire saw and cutting equipment, which is applied to stone processing equipment, work accessories, fine working devices, etc., can solve the problems of complex operation of diamond wire saw, affecting cutting accuracy, reducing cutting efficiency, etc., and achieves a simple working method. The effect of fast, reduced labor intensity and fast cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

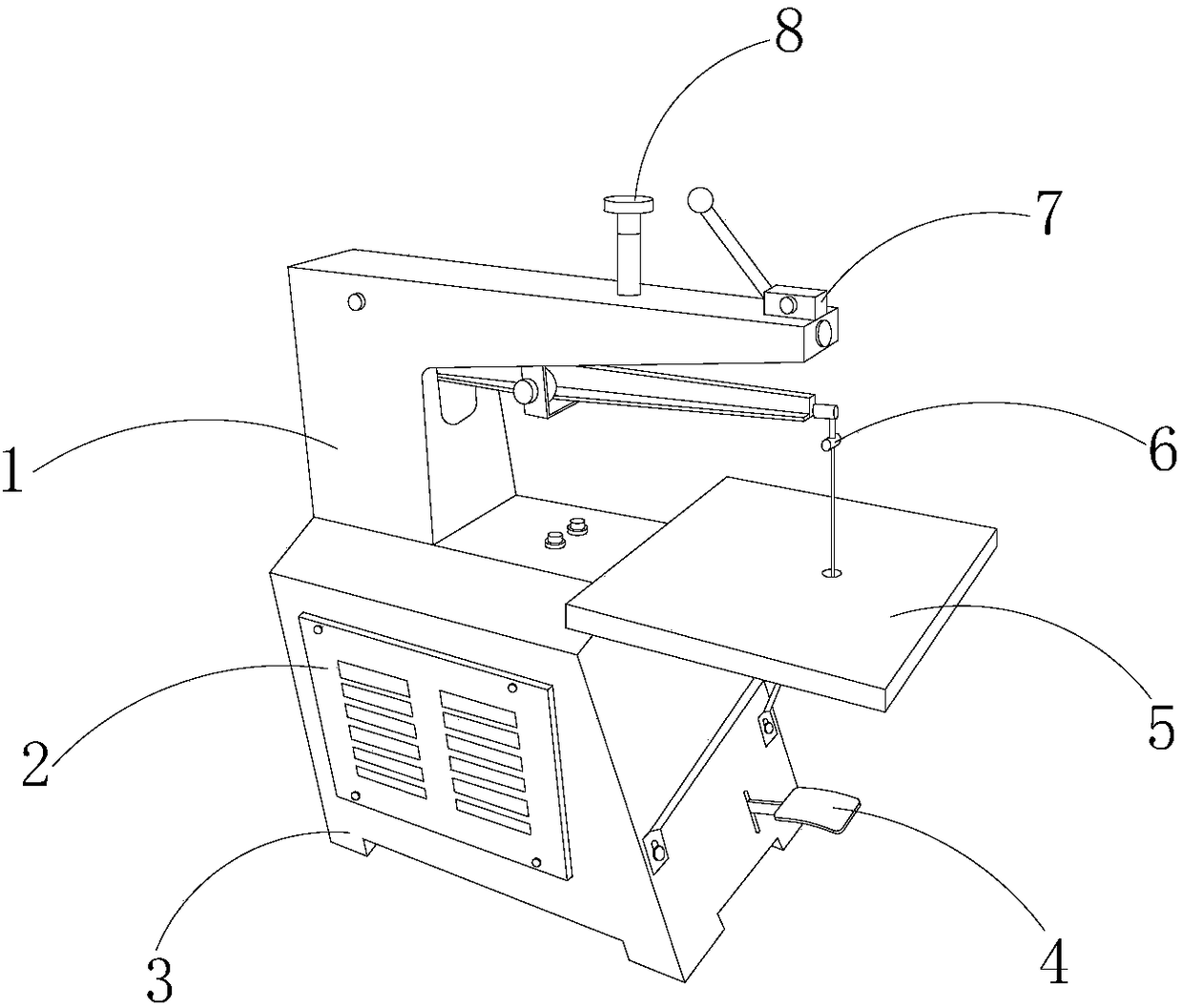

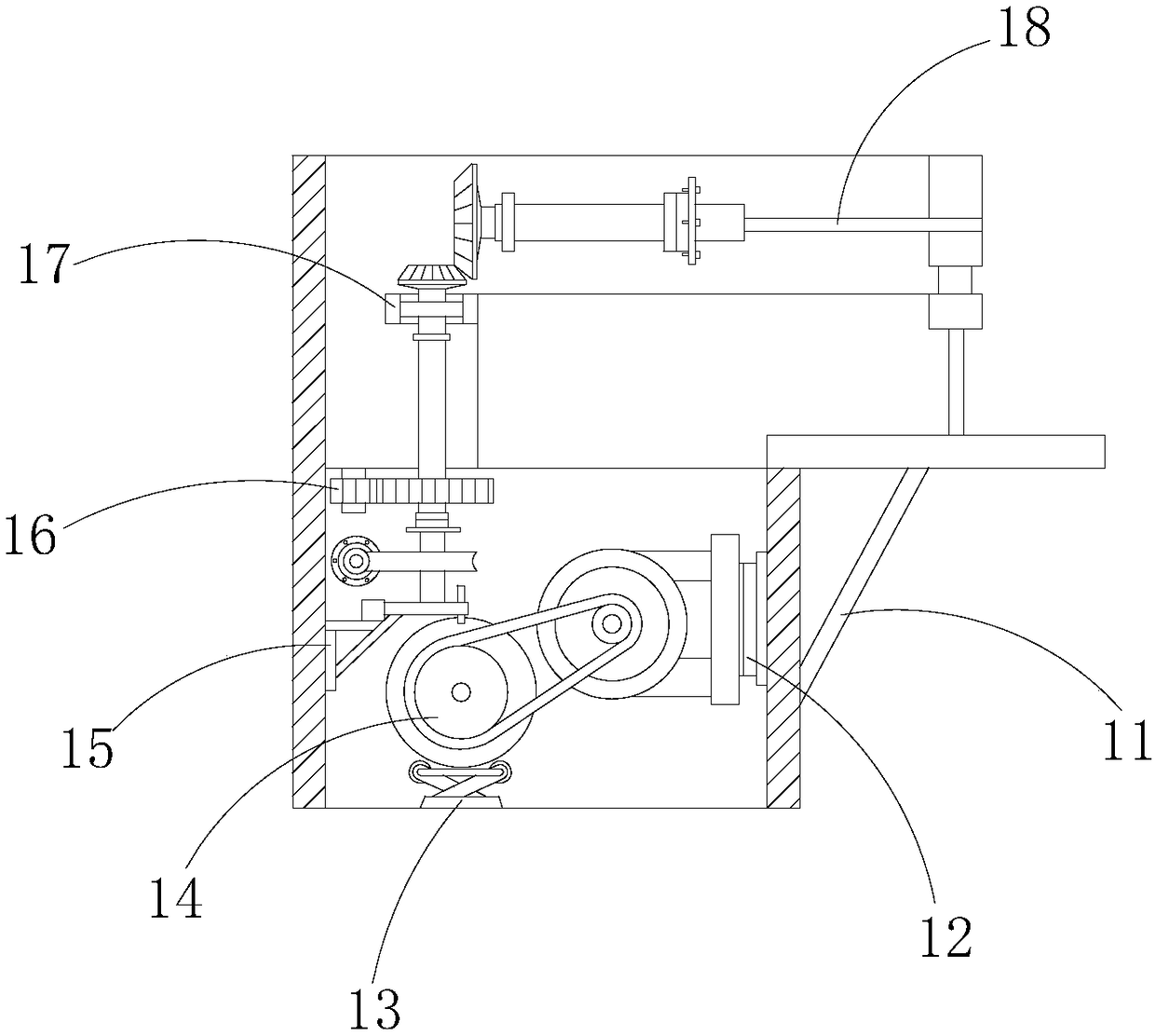

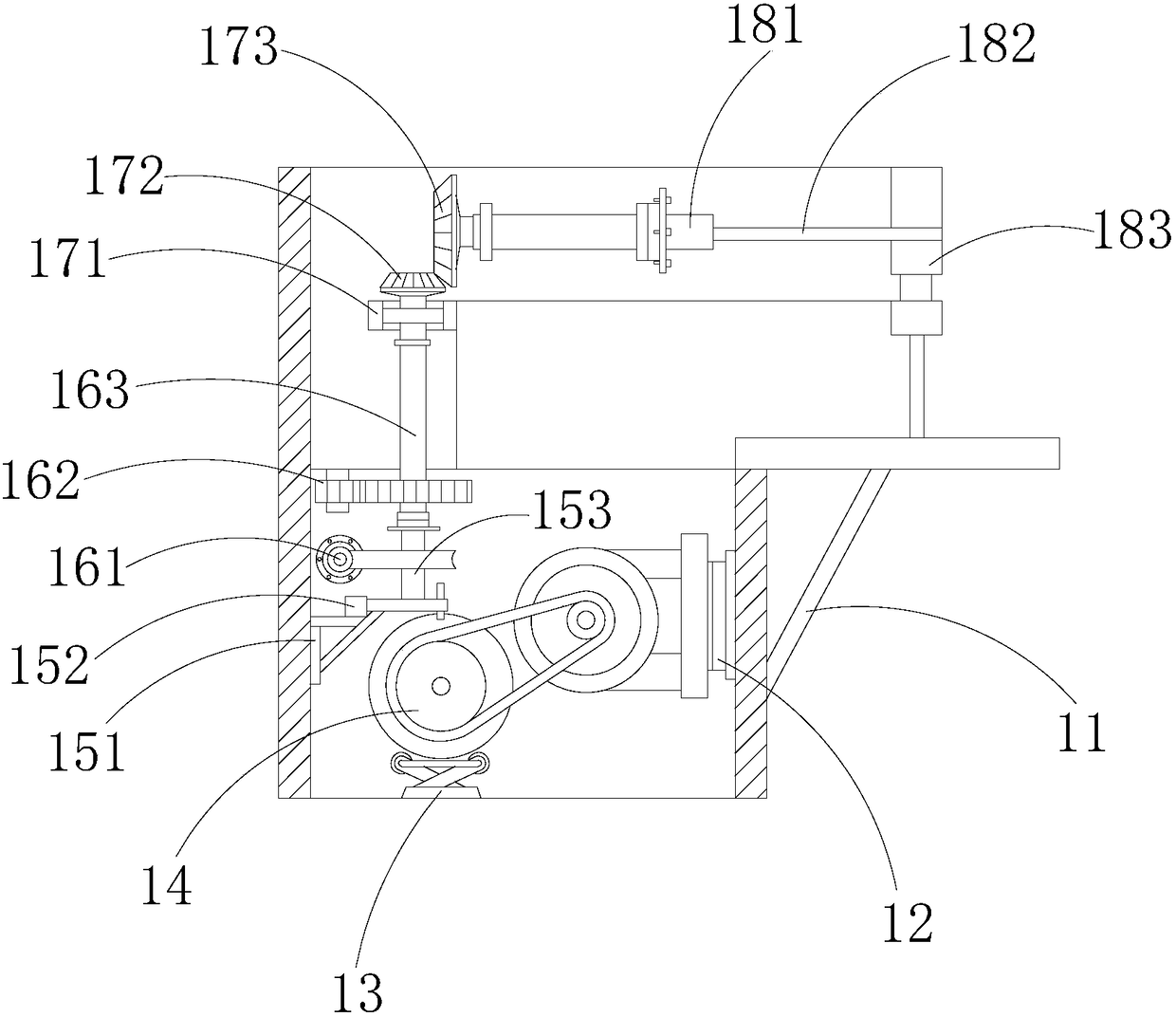

[0021] Such as Figure 1-Figure 5As shown, the present invention provides a diamond wire saw cutting device whose structure includes: a cutting device 1, a heat dissipation mechanism 2, a supporting foot 3, a pedal 4, a workbench 5, a diamond wire saw 6, a loading and unloading wire saw wrench 7, Wire saw tension adjustment knob 8, the cutting device 1 is vertically installed on the upper end of the supporting foot 3 and adopts a clearance fit, and the heat dissipation mechanism 2 is provided with two, which are evenly attached to the left and right ends of the cutting device 1 and integrated The support feet 3 are provided with a total of four and are evenly fixed on the bottom end of the cutting device 1 and welded together. The pedal 4 is horizontally installed on the side end of the cutting device 1 and is mechanically connected. The working The table 5 has a rectangular cross-section and is vertically installed on the upper end of the pedal 4 and adopts an interference fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com