Granule casing and automatic stacking unit

A kind of material boxing and automatic technology, which is applied in packaging, solid materials, transportation and packaging, etc., can solve the problems of material backlog in the buffer tank, prone to negative pressure, unfavorable economic benefits, etc., and achieve the effect of easy adjustment of material cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

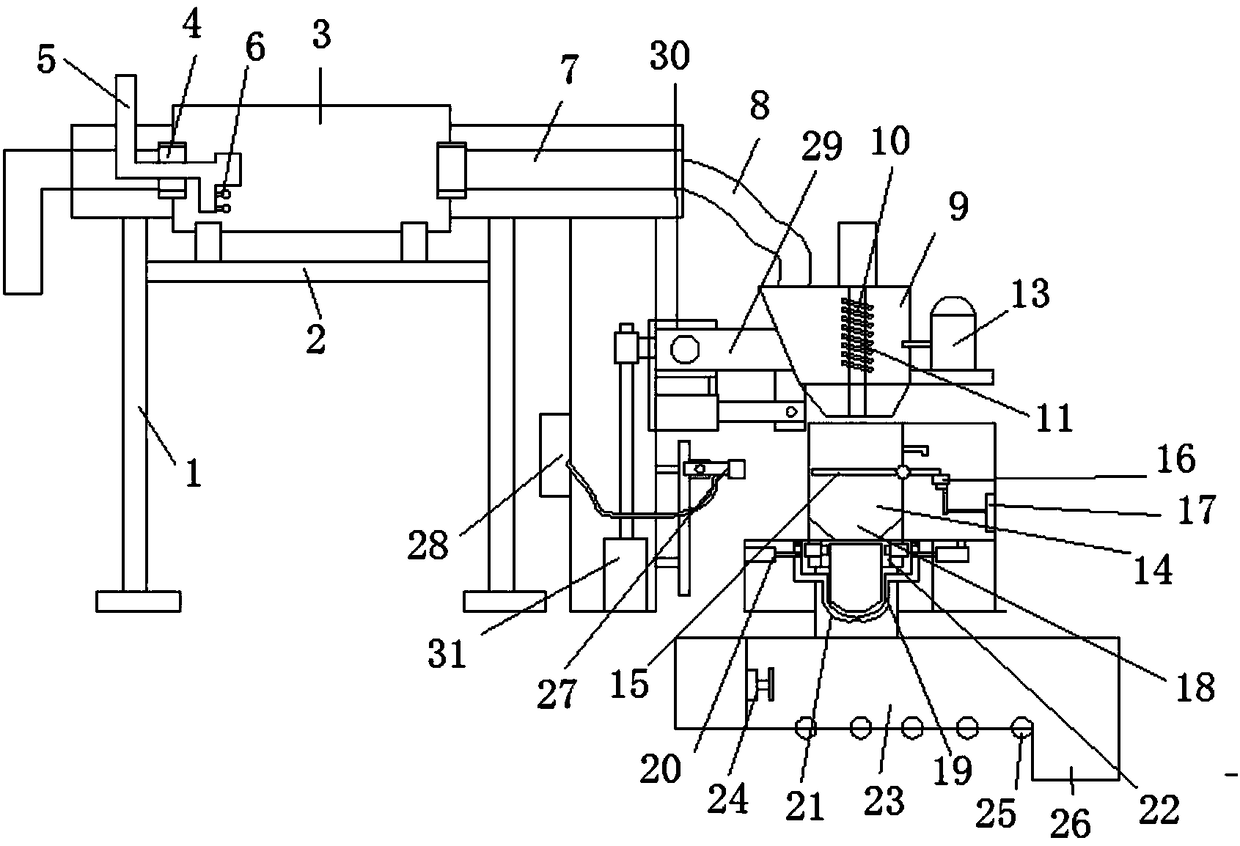

[0010] Referring to the accompanying drawings, a granular material boxing and automatic palletizing unit includes a bracket, a rotating seat 2 is fixedly installed on the bracket 1, a rotating drum 3 is installed on the rotating seat 2, and the rotating drum 3 The left end is provided with feed inlet 4, and described feed inlet 4 is provided with cooling and drying gas injection pipe 5, and the side wall of described cooling and drying gas injection pipe 5 is provided with temperature sensor 6, and the right end of described rotary cylinder 3 is provided with There is a conveying pipeline 7, and the lower end of the conveying pipeline 7 is connected to the unloading buffer cylinder 9 through a hose 8, and a rotating shaft 10 is arranged inside the unloading buffer cylinder 9, and a screw stopper is provided on the side wall of the rotating shaft 10 plate 11, a booster pump 13 is communicated with the side wall of the blanking buffer cylinder, a weighing cylinder 14 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com