Diesel oil, ethanol and tetrahydrofuran mixed fuel applicable to diesel engine

A tetrahydrofuran and mixed fuel technology, applied in fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve the problems of good ignitability, poor volatility of diesel oil, and insufficient mixing of fuel and air, so as to reduce emissions, reduce emissions, The effect of promoting the oil-gas mixing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

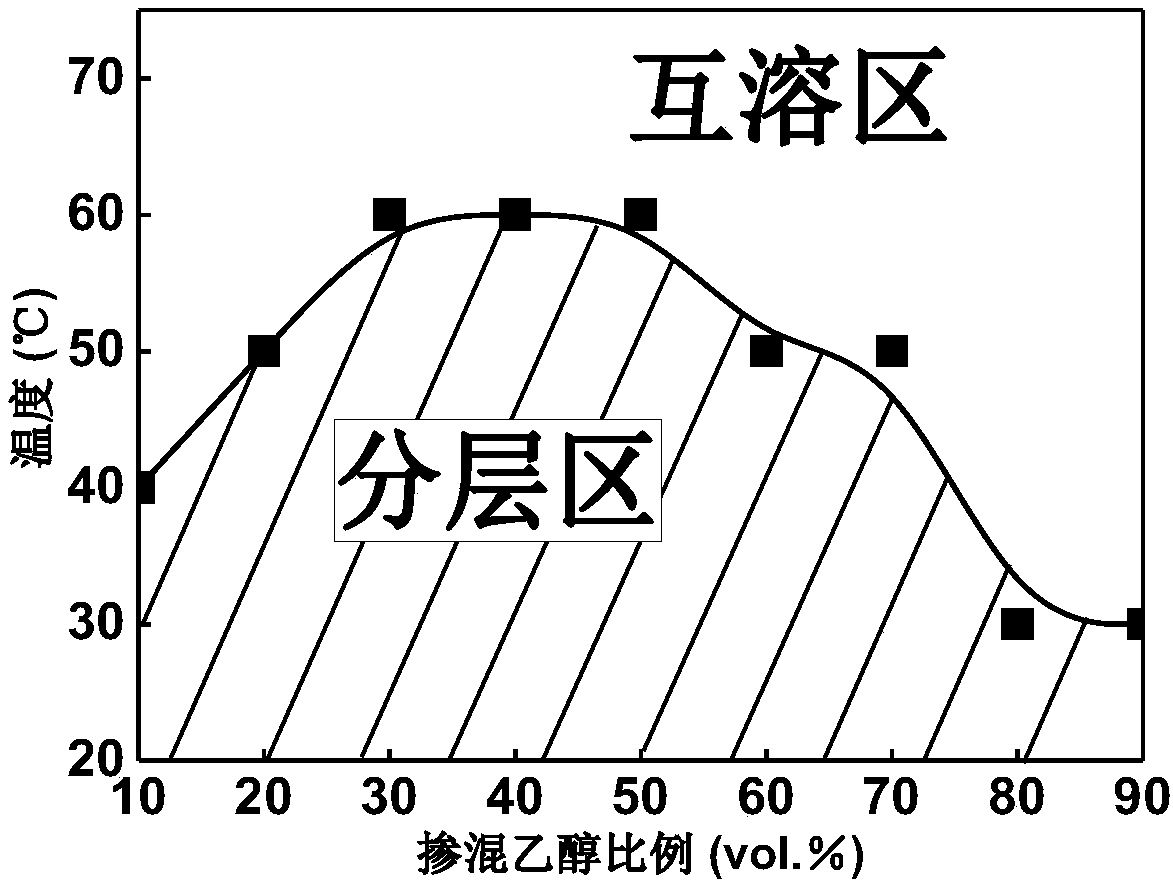

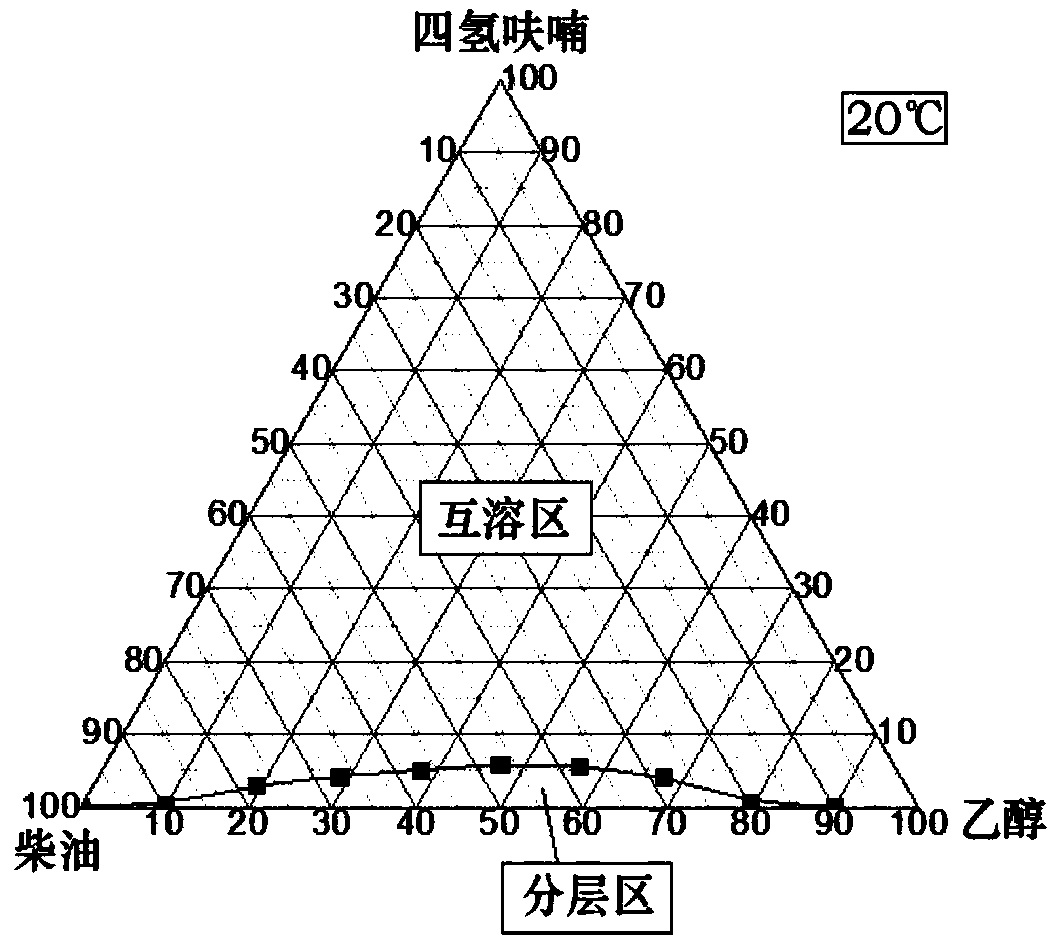

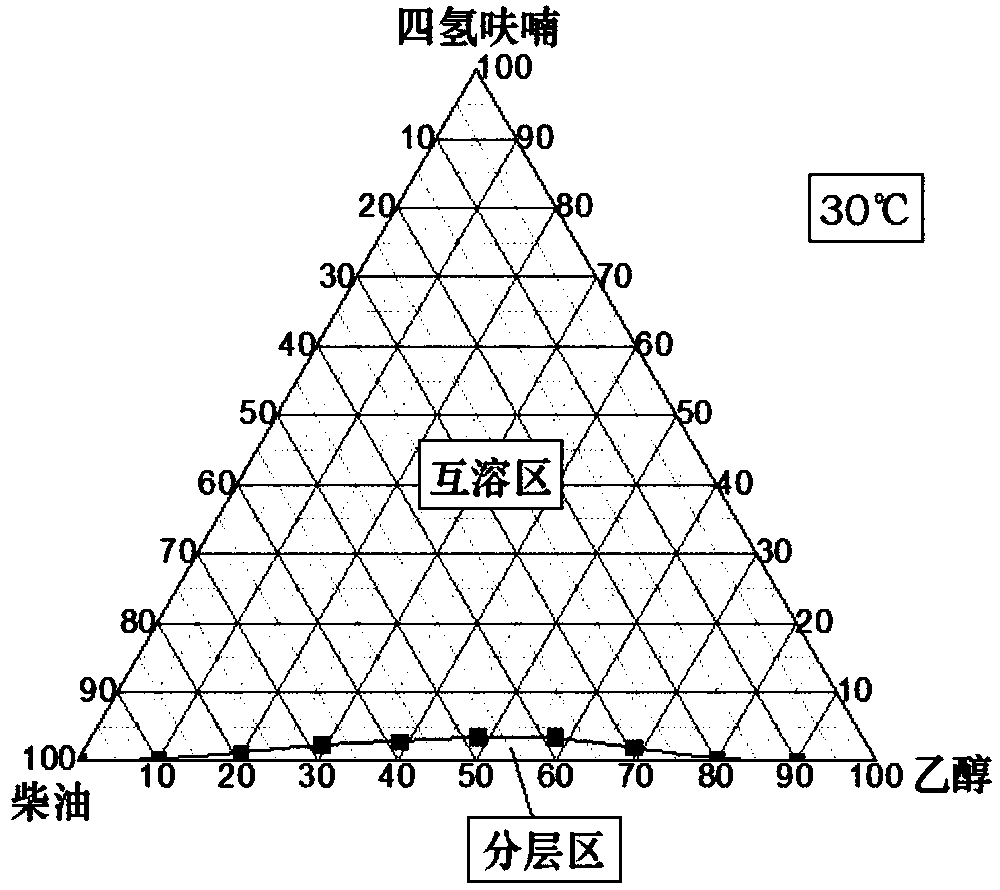

Method used

Image

Examples

Embodiment 1

[0027] Commercially available diesel oil 44L, ethanol 44L, tetrahydrofuran 12L.

Embodiment 2

[0029] Commercially available diesel oil 46L, ethanol 46L, tetrahydrofuran 8L.

Embodiment 3

[0031] Commercially available diesel oil 45L, ethanol 45L, tetrahydrofuran 10L.

[0032] Three kinds of different mixed fuels of embodiment 1 to embodiment 3 are tested on a heavy-duty diesel engine with a displacement of 8.42L, and the results show that the exhaust smoke of the novel mixed fuel provided by the present invention is obviously lower than that of pure diesel oil or diesel oil / tetrahydrofuran The two-component mixed fuel can reach more than 50%, and both CO and THC are reduced to varying degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com