Palm oil/ethanol/n-butyl alcohol mixed fuel suitable for diesel engine

A technology of mixed fuel and palm oil, which is applied in the direction of fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve the problems that there are no related reports on palm oil/ethanol/n-butanol mixed fuel, and achieve the reduction of emissions and the source of raw materials Broad, emission-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the fuel of the present invention comprises the following steps: measure each component according to the volume ratio, first add ethanol to palm oil to form an incomplete miscible mixed solution, and then add n-butanol to the mixed solution under stirring and mix evenly, namely Have to reconcile the fuel mix. This blended fuel is recommended to be blended at a temperature range of 30°C-60°C.

[0028] The kinematic viscosity of the novel mixed fuel containing ethanol provided by the invention is 2.08-4.20mm 2 / s, meeting the fuel viscosity range of 2.0-4.5mm suitable for traditional diesel engines 2 / s.

[0029] The novel mixed fuel provided by the invention has good mutual solubility of palm oil / ethanol / n-butanol, and the obtained mixed fuel has no stratification during long-term storage.

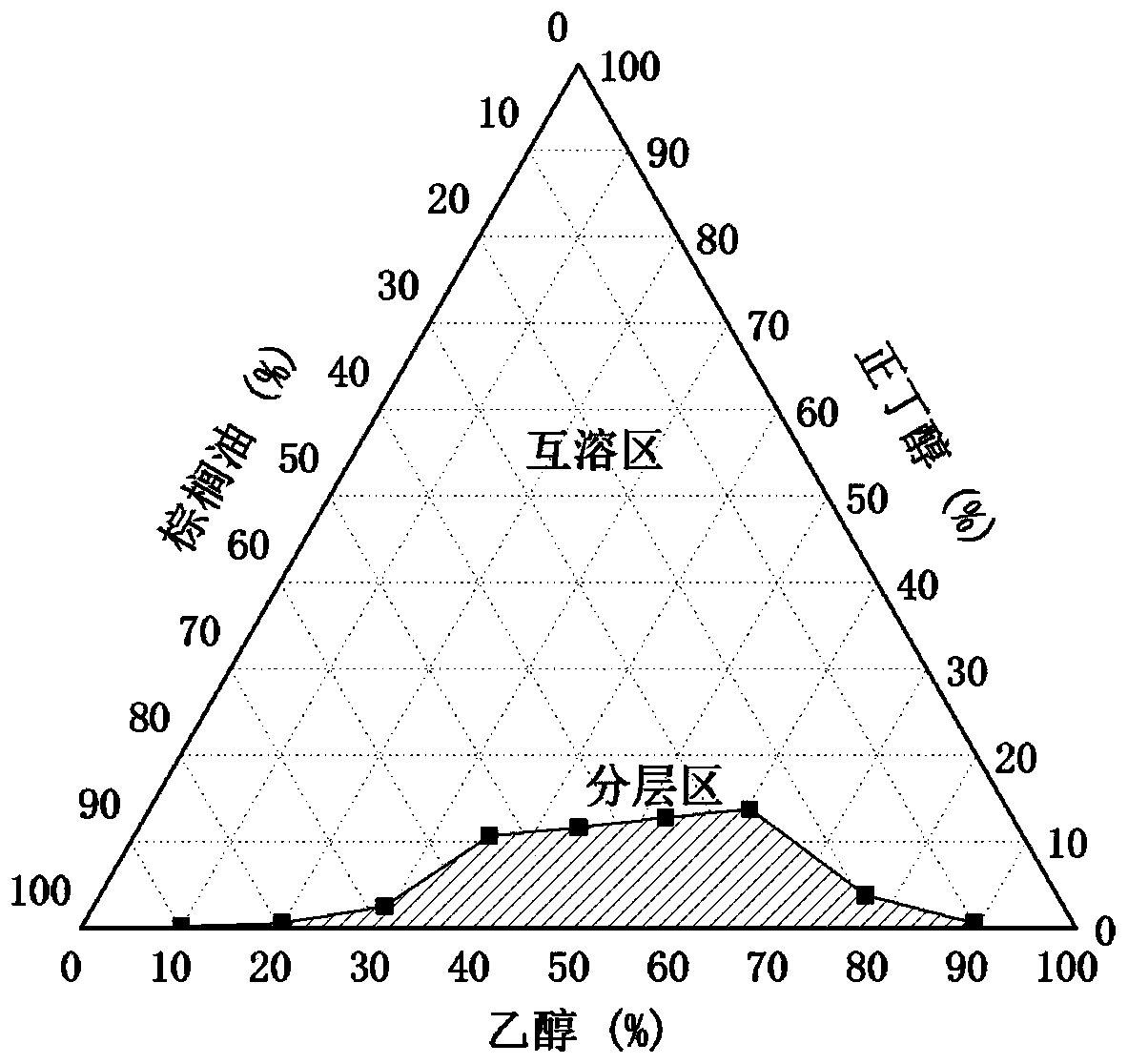

[0030] At 40°C, when the blending ratio of ethanol is between 10% and 90%, the miscibility of palm oil and ethanol cannot be realized. but from figure ...

Embodiment 1

[0033] Ethanol 20.5L, palm oil 20.5L, n-butanol 9L.

[0034] Described palm oil is commercially available grade 24 degree palm oil.

[0035] The ethanol mass percentage concentration is 99.5%.

[0036] The mass percent concentration of n-butanol is equal to 99.5%.

[0037] Configuration method: first add ethanol to palm oil to form an incomplete miscible mixture, then add n-butanol to the mixture under stirring and mix evenly to obtain a blended fuel mixture.

[0038] Tested: kinematic viscosity is 4.2mm 2 / s, to meet the requirements of diesel engines.

Embodiment 2

[0040] Ethanol 30L, palm oil 13L, n-butanol 7L.

[0041] Described palm oil is commercially available grade 24 degree palm oil.

[0042] The mass percent purity of the ethanol is 99.5%.

[0043] The mass percent concentration of n-butanol is 99.6%.

[0044] The configuration method is the same as in embodiment 1

[0045] Tested: kinematic viscosity is 2.08mm 2 / s, to meet the requirements of diesel engines.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com