Corn oil/ethanol/tetrahydrofuran mixed fuel suitable for diesel engine

A technology of tetrahydrofuran and mixed fuel, which is applied in the direction of fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve problems such as no reports of corn oil/ethanol/tetrahydrofuran mixed fuel, and achieves the promotion of oil and gas mixing process, wide range of raw material sources, Overcome the effects of over-dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the fuel of the present invention comprises the following steps: measure each component according to the volume ratio, first add ethanol into corn oil to form an incomplete miscible mixed solution, and then add tetrahydrofuran into the mixed solution under stirring and mix evenly to obtain a blend mixed fuel. The mixing temperature is preferably between 40-50°C.

[0026] The kinematic viscosity of the novel mixed fuel containing ethanol provided by the invention is 3.04~4.26mm 2 / s, meeting the fuel viscosity range of 2.0-4.5mm suitable for traditional diesel engines 2 / s.

[0027] The novel mixed fuel provided by the invention has good mutual solubility of corn oil / ethanol / tetrahydrofuran, and the obtained mixed fuel has no stratification during long-term storage.

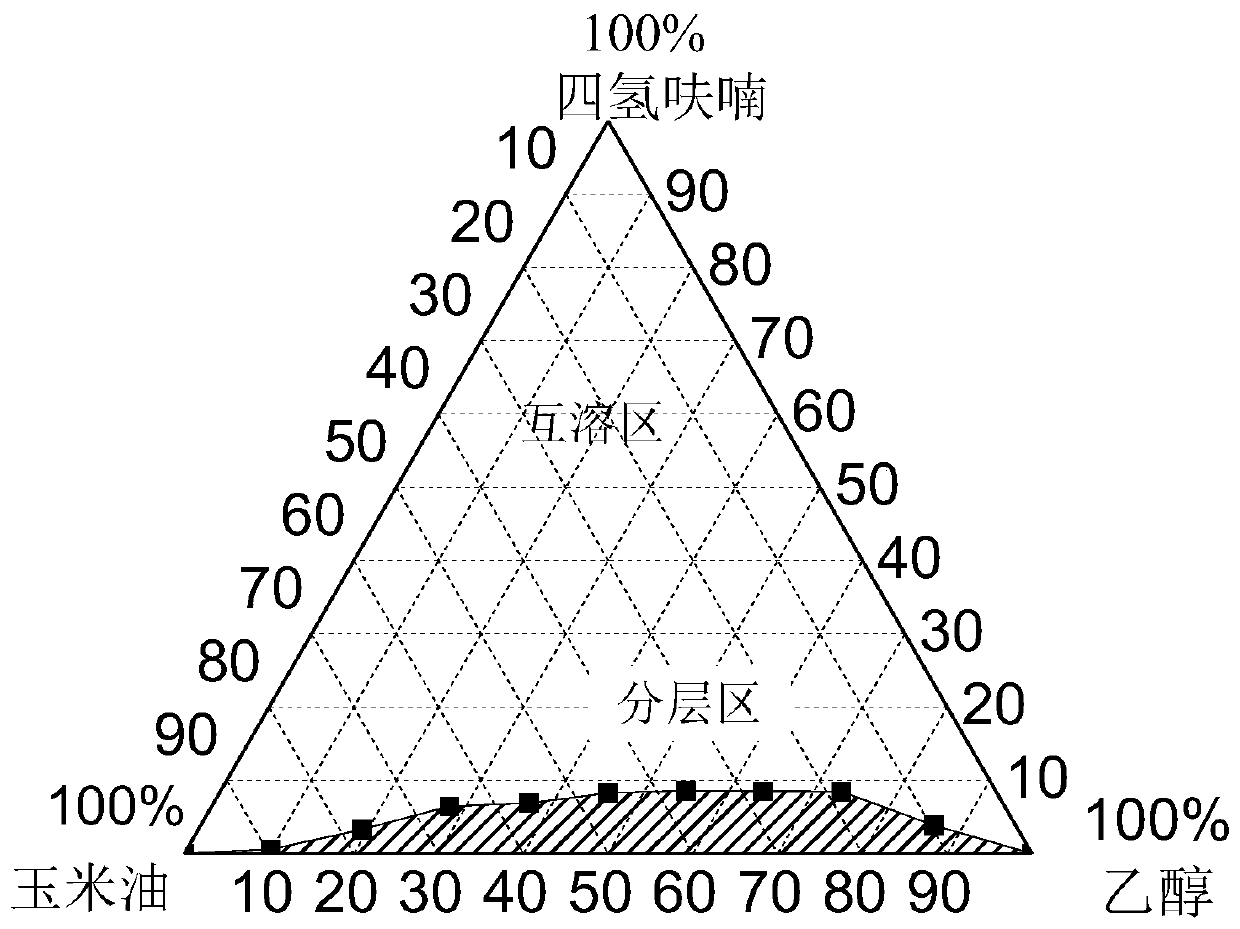

[0028] At 40°C, when the blending ratio of ethanol is between 10% and 90%, the miscibility of corn oil and formazan / ethanol cannot be realized. but from figure 1 It can be see...

Embodiment 1

[0032] Ethanol 11.0L, corn oil 7.4L, tetrahydrofuran 1.6L.

[0033] The corn oil is commercially available grade one corn oil. The ethanol mass percentage concentration is 99.9%. The mass percent concentration of THF is 99.5%.

[0034] Configuration method: first add ethanol to corn oil to form an incomplete miscible mixture, then add tetrahydrofuran to the mixture under stirring and mix evenly to obtain a blended fuel mixture. The mixing temperature is 40°C.

[0035] After testing, the kinematic viscosity of the mixed fuel is 3.09mm 2 / s, meeting the traditional diesel viscosity standard 2.0-4.5mm 2 / s request.

Embodiment 2

[0037] Ethanol 7.1L, corn oil 3.0L, tetrahydrofuran 1.0L.

[0038] The corn oil is commercially available first-grade transgenic corn oil. The ethanol mass percentage concentration is 99.9%. The mass percent concentration of THF is 99.5%.

[0039] The configuration method is the same as in embodiment 1

[0040] After testing, the kinematic viscosity of the mixed fuel is 4.26mm 2 / s, meeting the traditional diesel viscosity standard 2.0-4.5mm 2 / s request.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com