Corn oil/methanol/n-butyl alcohol mixed fuel suitable for diesel engine

A technology of mixed fuel and corn oil, which is applied in the direction of fuel, biofuel, liquid carbon-containing fuel, etc., can solve the problems of unstable mutual solubility, engine deflagration, and high fuel consumption, so as to promote the process of oil and gas mixing, solve excessive dependence, and source of raw materials wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

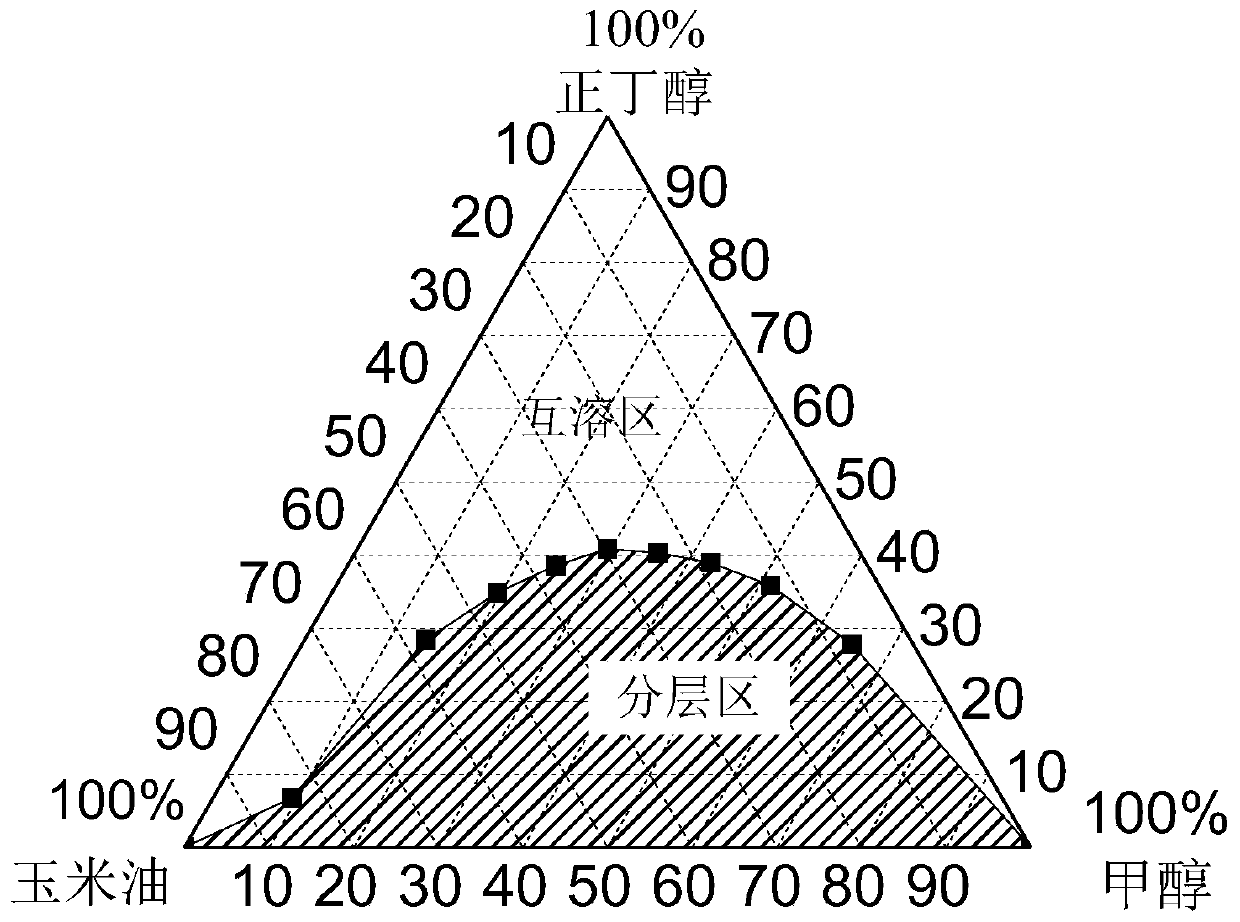

[0022] The preparation method of the above-mentioned fuel of the present invention comprises the following steps: measure each component according to the volume ratio, first add methanol into corn oil to form an incomplete miscible mixed solution, then add n-butanol into the mixed solution under stirring and mix evenly, That is to reconcile the mixed fuel. The mixing temperature is preferably between 30°C and 50°C.

[0023] By testing the kinematic viscosity of the novel mixed fuel containing methanol provided by the present invention is 2.43-4.31mm 2 / s. The diesel kinematic viscosity suitable for conventional diesel engines is 2.0-4.5mm 2 / s, so the novel mixed fuel containing methanol provided by the present invention can be applied in diesel engines.

[0024] The novel mixed fuel provided by the invention has good mutual solubility of corn oil / methanol / n-butanol, and the obtained mixed fuel has no stratification during long-term storage.

[0025] At 40°C, when the blen...

Embodiment 1

[0029] Methanol 20L, corn oil 12.5L, n-butanol 17.5L.

[0030] The corn oil is commercially available national first-grade transgenic corn oil. The mass percent concentration of methanol is 99.5%. The mass percent concentration of n-butanol is 99.0%.

[0031] Configuration method: first add methanol to corn oil to form an incomplete miscible mixture, then add n-butanol to the mixture under stirring and mix evenly to obtain a blended fuel. The mixing temperature was 40°C.

[0032] Tested: kinematic viscosity is 4.31mm 2 / s, to meet the requirements of diesel engines.

Embodiment 2

[0034] Methanol 30L, corn oil 7.5L, n-butanol 12.5L.

[0035] The corn oil is commercially available national first-grade transgenic corn oil. The mass percent concentration of methanol is 99.9%. The mass percent concentration of n-butanol is 99.5%.

[0036] The configuration method is the same as in embodiment 1

[0037] Tested: kinematic viscosity is 2.43mm 2 / s, to meet the requirements of diesel engines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com