Weft insertion device of special-shaped fabric loom and special-shaped fabric loom

A technology of weft insertion device and weft insertion mechanism, which is applied to looms, textiles, papermaking, textiles, etc., can solve the problems of inability to weave three-dimensional special-shaped fabrics, solve the problem of uneven yarn density, reduce labor costs, and increase efficiency. effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

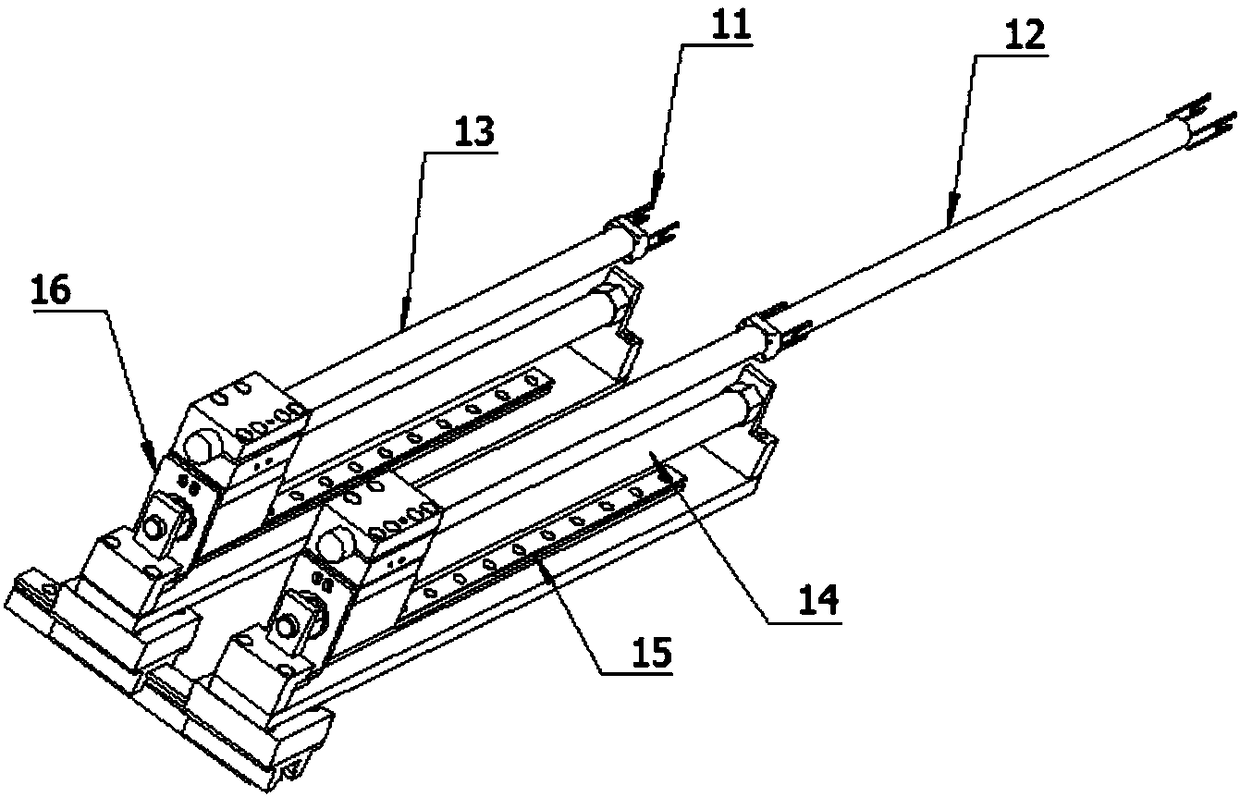

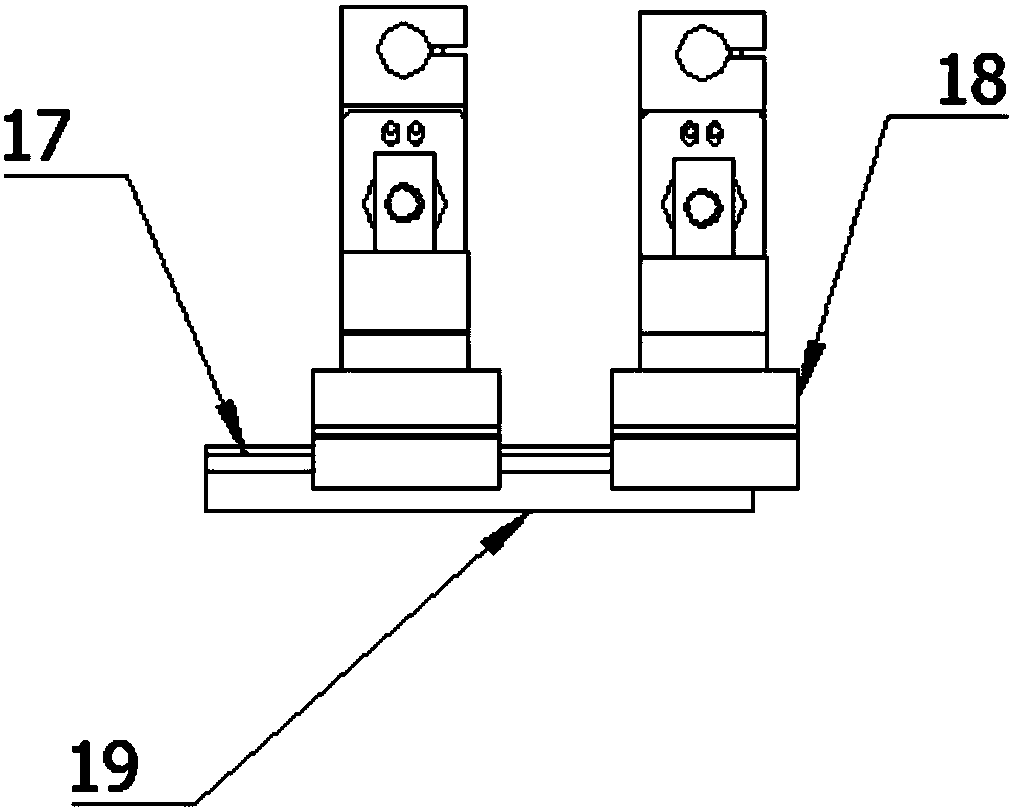

[0041] Such as Figure 1-Figure 8 As shown, the weft insertion device of the special-shaped fabric loom includes a weft insertion mechanism 6, a side line mechanism 32, and a weft tensioning mechanism 4. The number of weft insertion mechanisms 6 is two, and each weft insertion mechanism 6 includes two weft insertion rods— - the first weft insertion rod 12 and the second weft insertion rod 13, the length of the first weft insertion rod 12 is greater than the second weft insertion rod 13, and the two weft insertion mechanisms 6 are respectively located on both sides of the woven fabric and along the woven fabric The center of the fabric is symmetrical in the length direction of the woven fabric.

[0042]By arranging two weft insertion rods at each weft insertion mechanism 6—the first weft insertion rod 12 and the second weft insertion rod 13, when weaving a fabric with a smaller length in the weft line 33 direction, a pair of first weft insertion rods 12 Carry out reciprocating...

Embodiment 2

[0060] Such as figure 1 As shown, this embodiment provides a special-shaped fabric loom, which is provided with any one of the weft insertion devices for the above-mentioned special-shaped fabric loom.

[0061] The special-shaped fabric loom has all the technical effects of the weft insertion device of the above-mentioned special-shaped fabric loom.

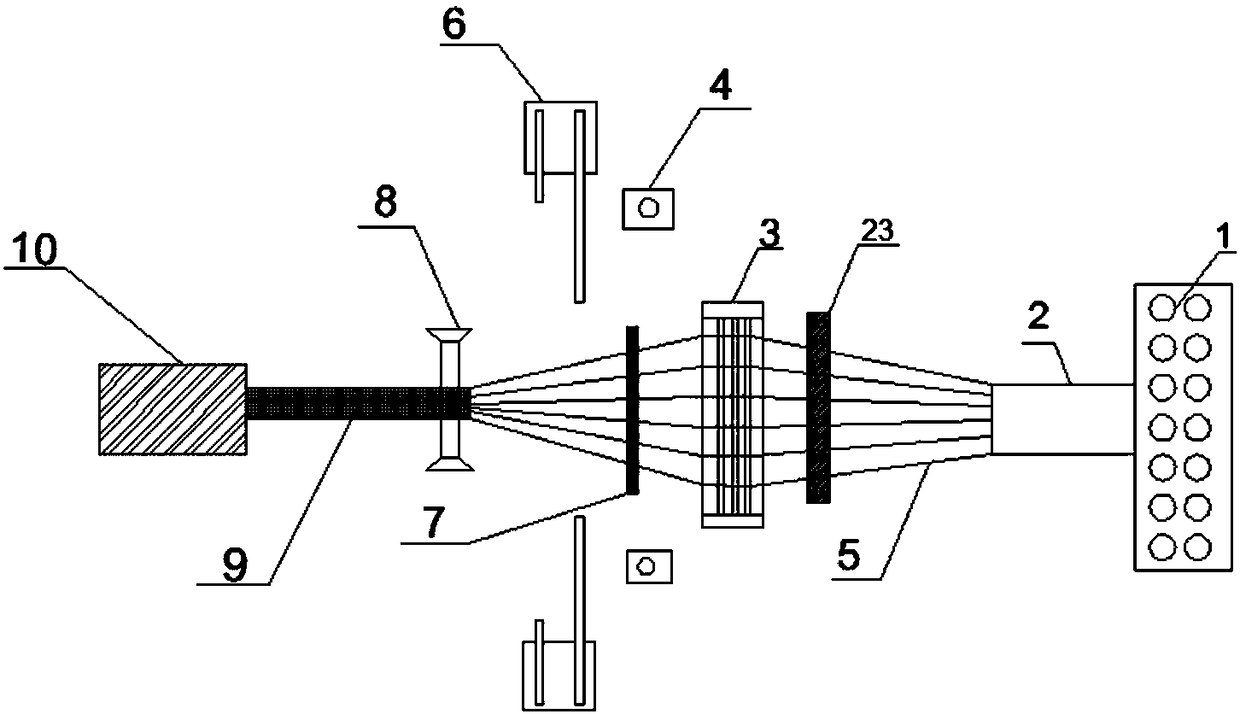

[0062] Specifically, this special-shaped fabric loom also includes a shed opening device 3, a weft beating device 7, a warp let-off device, a fabric clamping device 8 and a crimping device 10, taking the upstream to downstream of fabric production as the direction of description, wherein The warp thread 5 is tensioned and arranged between the warp let-off creel 1 and the heald lifting shed device 3, the heald lifting shedding device 3 is set between the beating device 7 and the warp thread tensioning device 2, and the weft beating device 7 is arranged on the heald lifting shedding device 3 And between the weft insertion mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com