Two-stage compression piston type air compressor crankcase rear end heavy hammer air valve air return path structure

A two-stage compression and air compressor technology, which is applied to liquid variable-capacity machinery, mechanical equipment, and variable-capacity pump components, etc. problems, to achieve the effect of eliminating the fracture and damage of the crankshaft, reducing the starting torque and reducing the power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

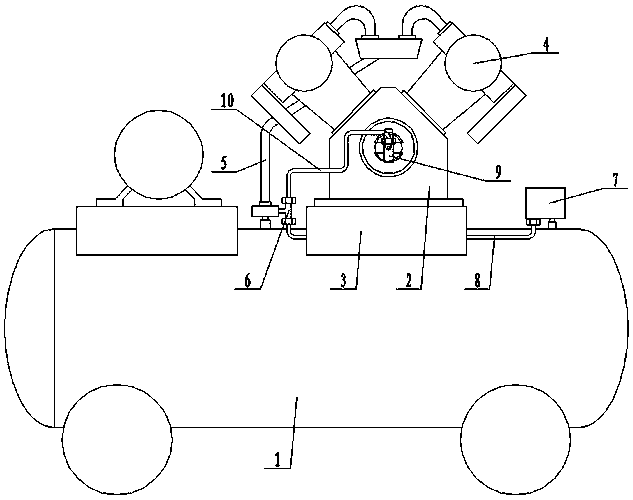

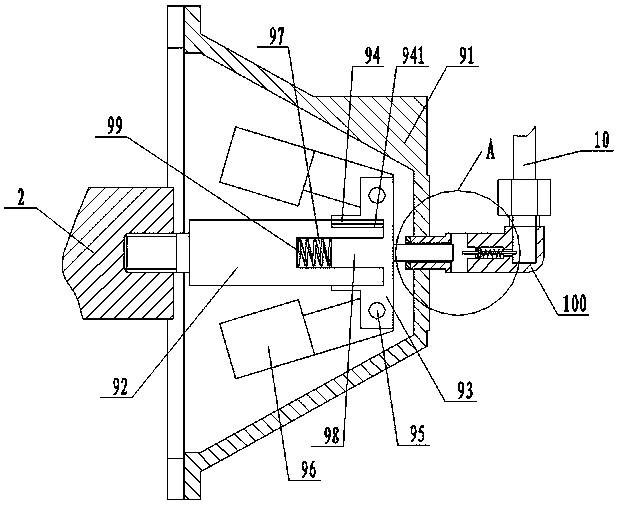

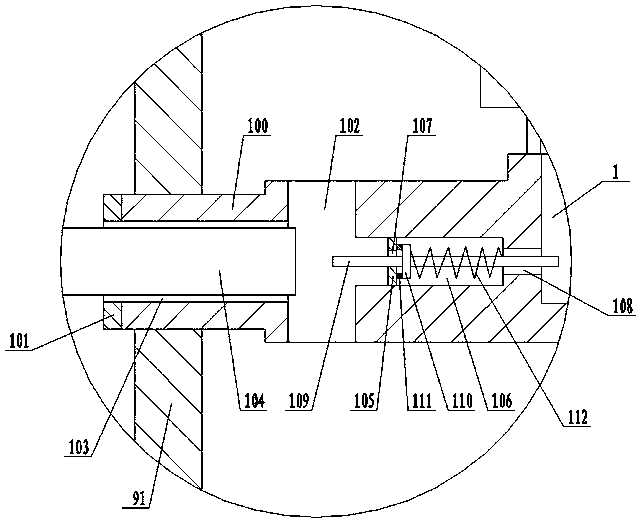

[0011] Such as figure 1 , figure 2 , image 3 As shown, the structure of the air return path of the heavy hammer valve at the rear end of the crankcase of the two-stage compression piston air compressor includes: the main body of the air compressor 1, and the crankcase 2 is installed on the main body 1 of the air compressor through the mounting seat 3. Both sides of the upper end of the crankcase 2 are provided with a cylinder 4, the cylinder 4 is connected with the air compressor main body 1 through an exhaust pipe 5, and a tee joint 6 communicating with it is provided on the exhaust pipe 5, An air pressure switch 7 is arranged on the main body 1 of the air compressor, and the air pressure switch 7 is connected to the three-way joint 6 through the main pipe 8 of the exhaust pipe, and a heavy hammer air valve is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com