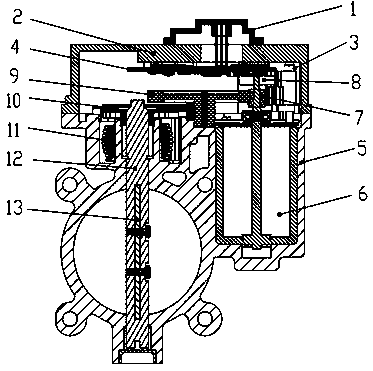

Intelligent butterfly valve driven by brushless motor

A brushless motor and intelligent technology, applied in the field of auto parts, can solve problems such as limiting the service life of brushed DC motors, reducing output efficiency, and product incompatibility, etc., to simplify the difficulty of structural design, increase reliability, and simplify control difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

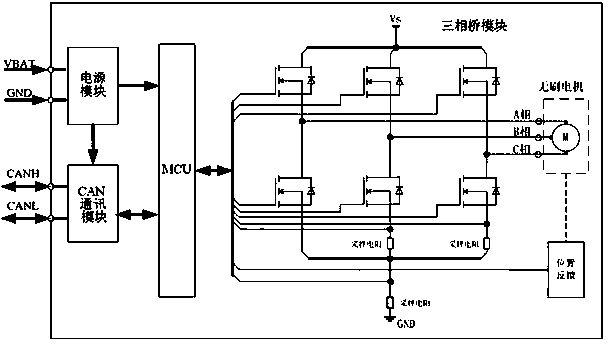

[0017] Brushless motor is a typical mechatronic product, which cancels the brush structure and uses semiconductor switching devices to realize electronic commutation, that is, replaces traditional contact commutators and brushes with electronic switching devices. Commutation sparks, low mechanical noise and other advantages. Therefore, the present invention uses a brushless motor to drive the butterfly valve, so as to become an intelligent electric actuator that can be driven only through the CAN bus, thereby improving the service life of the butterfly valve.

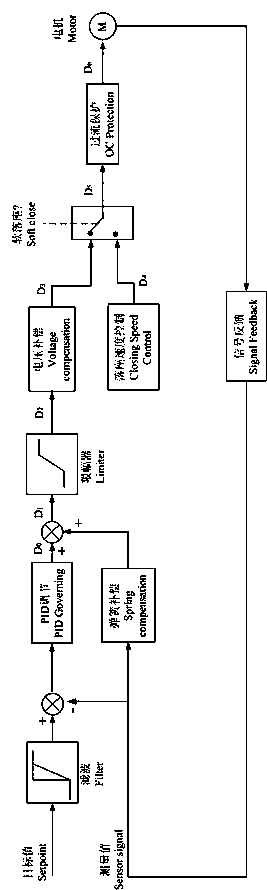

[0018] The core of brushless motor control is to know the current position of the rotor in real time, and to commutate at the correct time. Usually, the control method of brushless motor is to place three Hall switches at intervals of 120° inside the motor to detect the rotor. position, and then control the commutation time to realize the control of the brushless motor. Such a control method requires 8 pins (3 motor dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com