No-accessory constant-strength repair welding method based on pumpback type friction stir welding

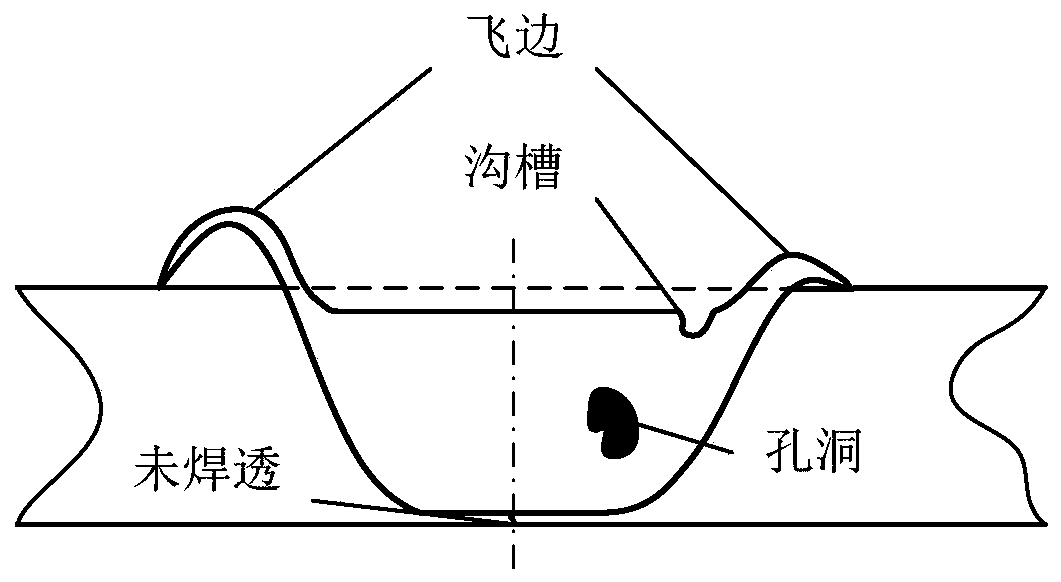

A friction stir welding, no auxiliary material technology, used in welding equipment, non-electric welding equipment, metal processing equipment and other directions, can solve the problems of randomness in the location and size of defects, weakened resistance to damage of welds, and rising repair welding costs. , to achieve the effect of controllable length, smooth and beautiful surface, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

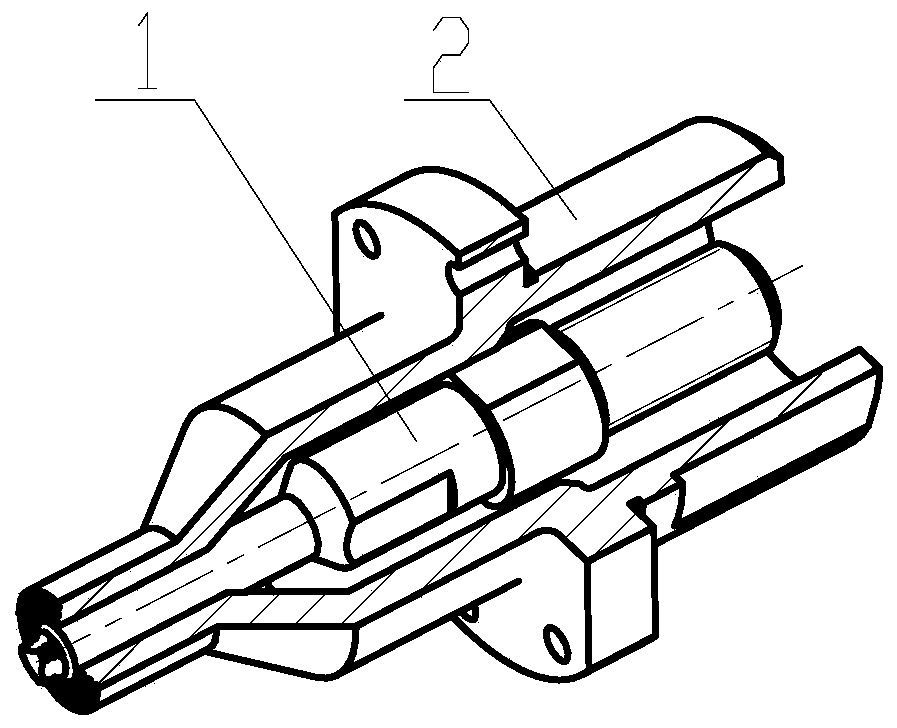

[0033]According to the material properties and geometric characteristics of the welding, select the appropriate stirring head and welding process parameters. Assuming that the width of the missing material area is 2p, repair welding is carried out in two steps. In the first step, take the center of the missing material area as the symmetry line ( image 3 ), offset the welding trajectory to one side with a distance of p, so that the central symmetry line after the offset is located on the receding side of the welding trajectory ( image 3 ), for welding. After the stirring head moves out of the existing area and completes the repair welding, continue to move forward, and at the same time withdraw the stirring needle into the shoulder at a certain speed, and finally obtain a weld without "keyhole"; the second step is to move the welding track to the symmetrical The other side of the line is offset, and the offset distance is also p, so that the center symmetric line after off...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com