Climbing inspection robot used for high voltage transmission line power tower

A technology of high-voltage transmission lines and inspection robots, which is applied in the field of electric power, can solve problems that affect work efficiency, danger, and consume the physical strength of maintenance personnel, and achieve the effects of ensuring stable operation, reducing risk factors, and avoiding the probability of safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

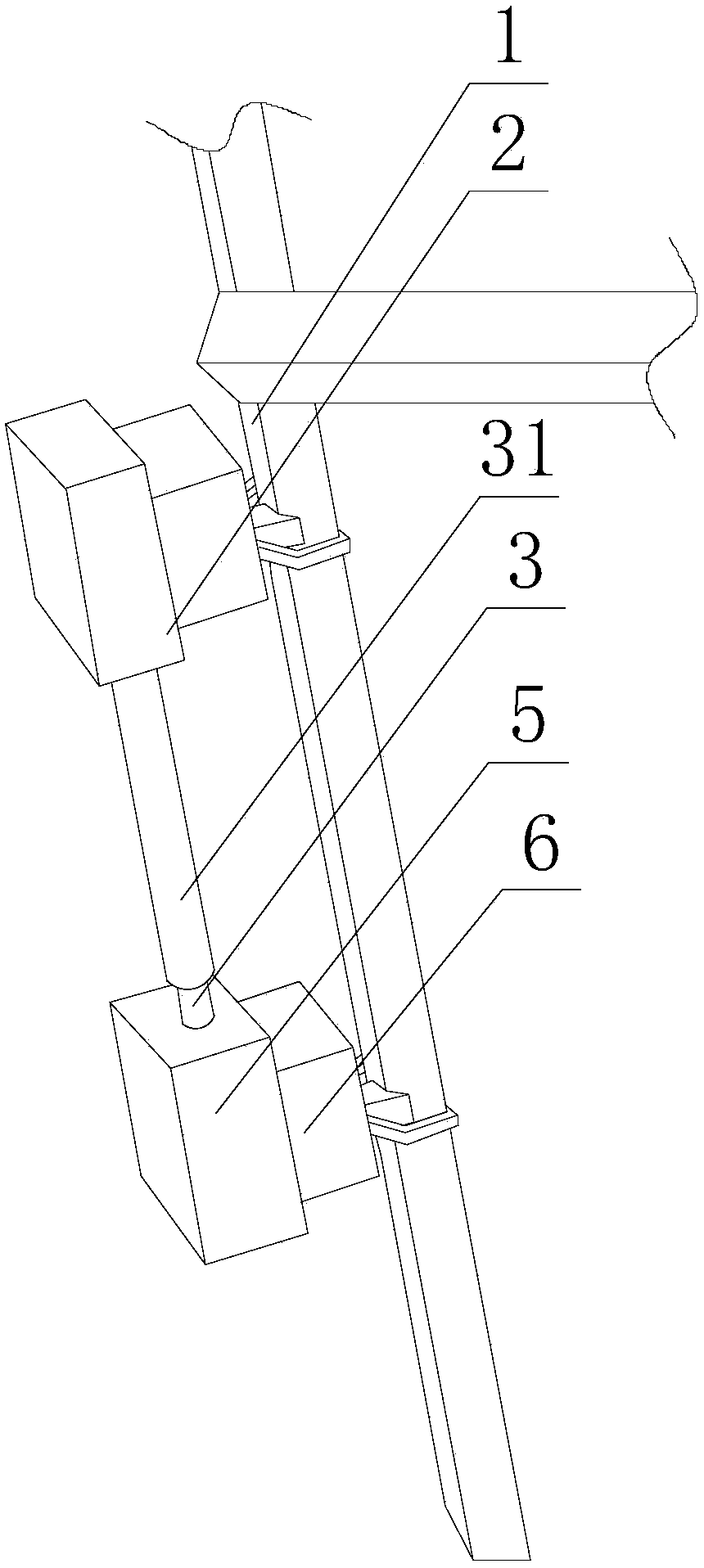

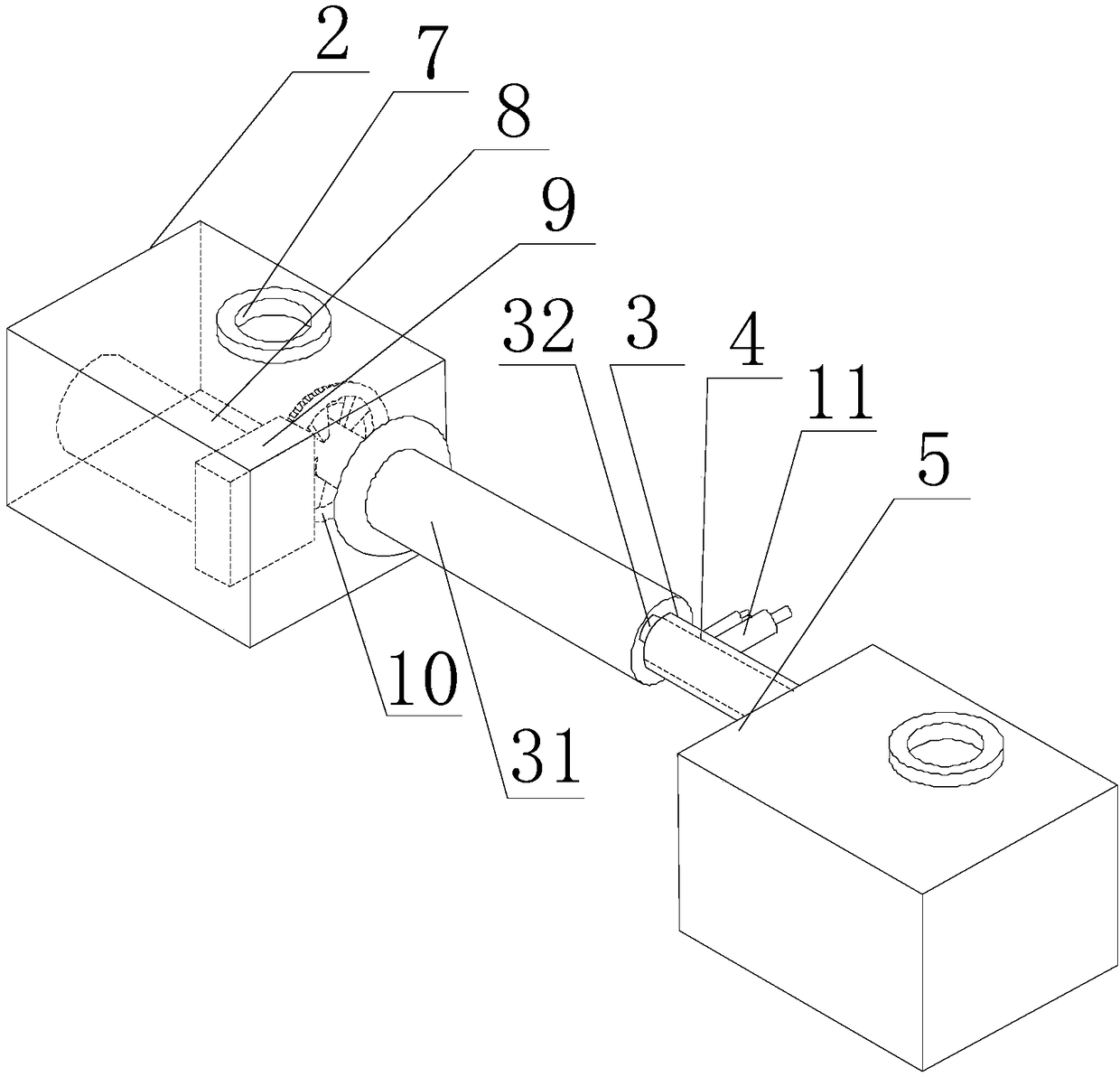

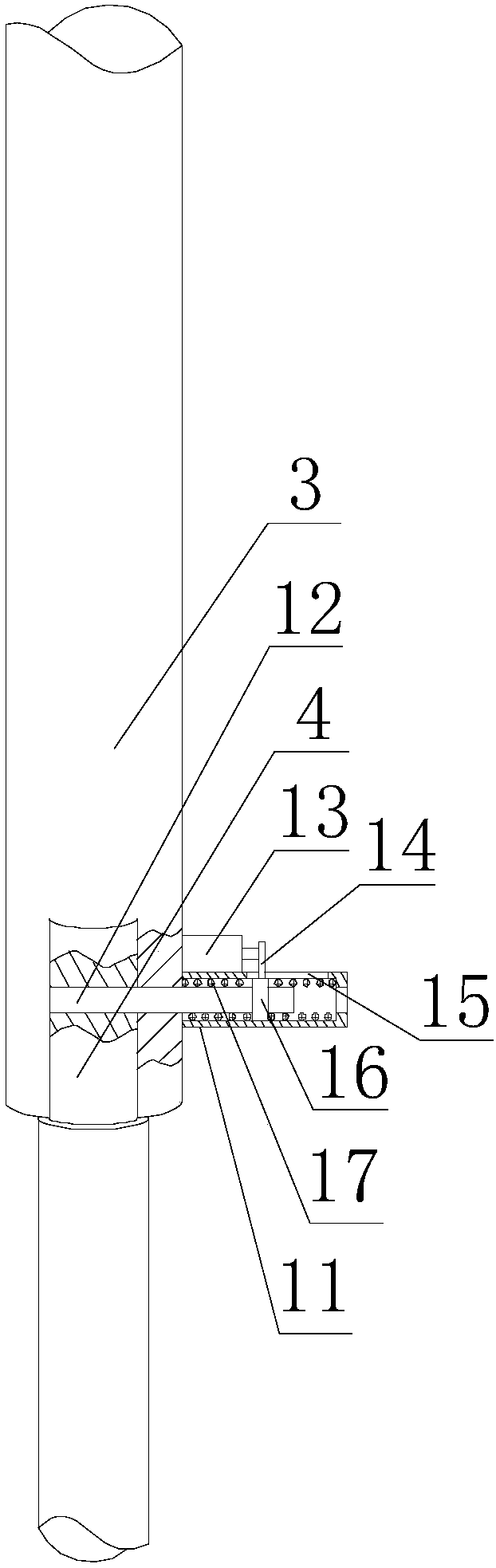

[0026] Such as Figure 1~6 As shown, the present embodiment includes an upper box body 2 and a lower box body 5. A guide cylinder 31 is provided on the upper box body 2, and a connecting cylinder 3 is provided on the lower box body 5. In the axial direction, a protrusion 32 is provided on the outer peripheral wall fan, and a groove matching the protrusion 32 is formed on the inner peripheral wall of the guide cylinder 31 along the axial direction. The screw rod 4 threaded on the inner circumference wall of the barrel 3 is also provided with a main motor 8 in the upper box body 2, and a main gear is installed on the output end of the main motor 8, and the screw rod 4 is installed on one end inside the upper box body 2. There are auxiliary gears 10 matched with the main gear; connecting holes 7 are provided on the side walls of the upper box body 2 and the lower box body 5 on the same side, and each connecting hole 7 is provided with Locking mechanism 6; the locking mechanism 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com