Method for improving propylene recovery of fcc recovery unit

A technology for feeding propylene and hydrocarbons, which is applied in separation methods, chemical instruments and methods, absorption purification/separation, etc., and can solve problems such as uneconomical and difficult high recovery of propylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

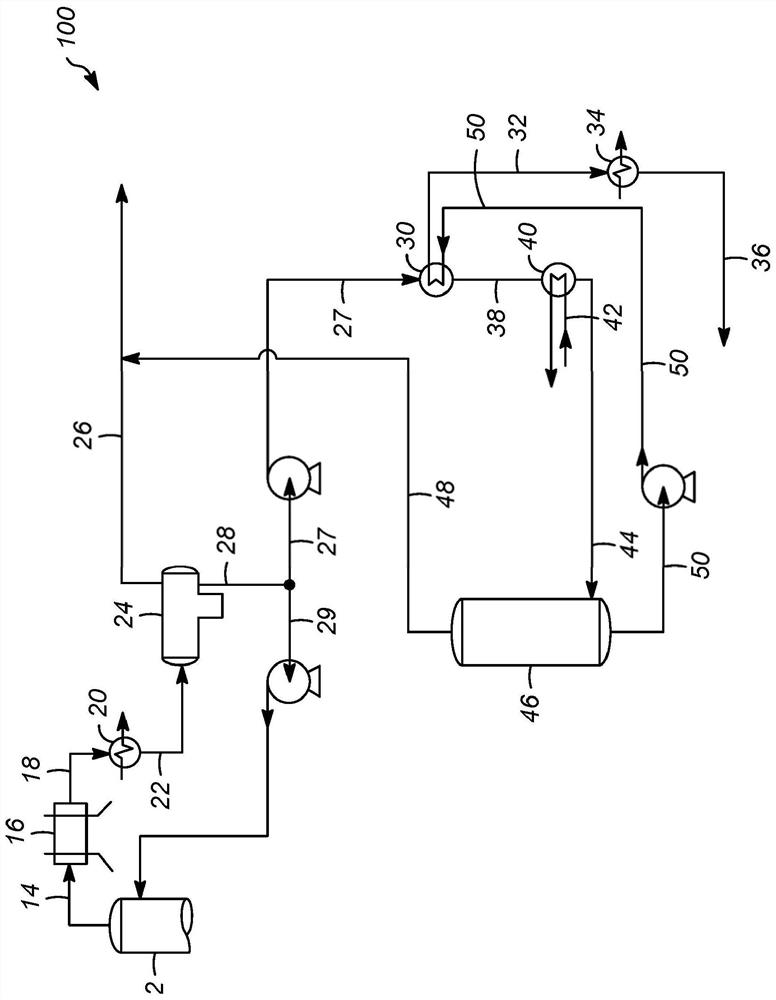

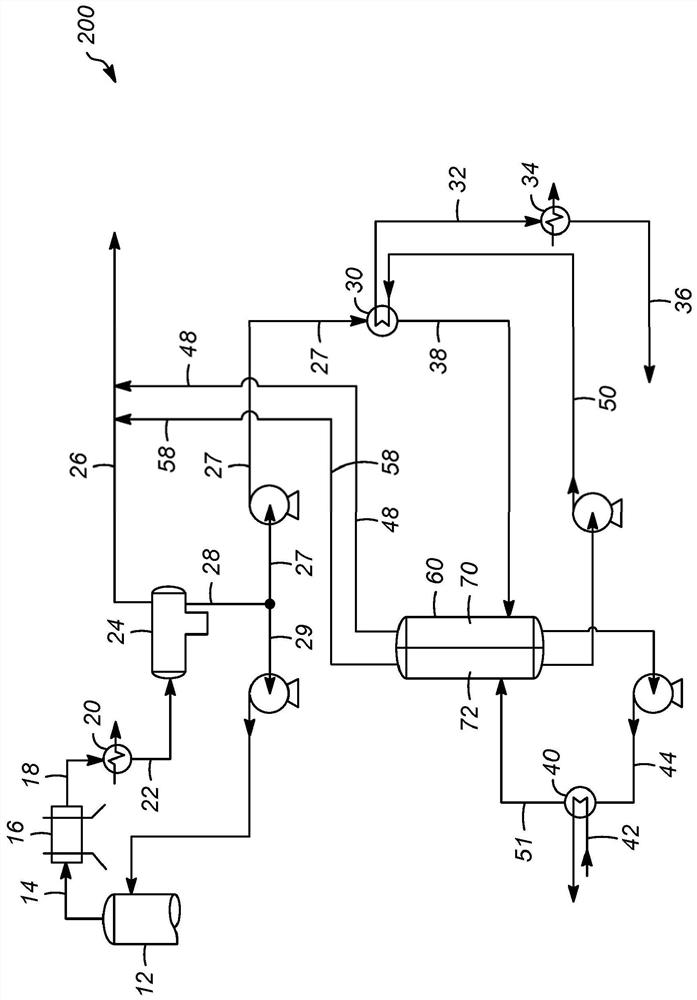

[0037] The FCC unit is designed according to the prior art process flow. A propylene recovery of 98.93 mole % can be achieved. Any additional propylene recovery using conventional methods is impossible and uneconomical. By adding this new invention to the design of the unit, higher recovery rates can be achieved, resulting in higher yields and a payback period of several months based on the cost of the new equipment. A comparison of the base case vs. the case of adding new equipment is shown in Table 1.

[0038] Table 1

[0039]

[0040] As shown in Table 1 above, higher propylene recoveries can be achieved with the new invention and the payback period for new equipment investment is expected to be several months. Also, perform the above analysis for the worst case scenario of using LP steam to heat unstabilized gasoline. Unstabilized gasoline can be heated in most cases with waste heat process streams available from gas recovery or FCC main fractionation sections. Thi...

Embodiment 2

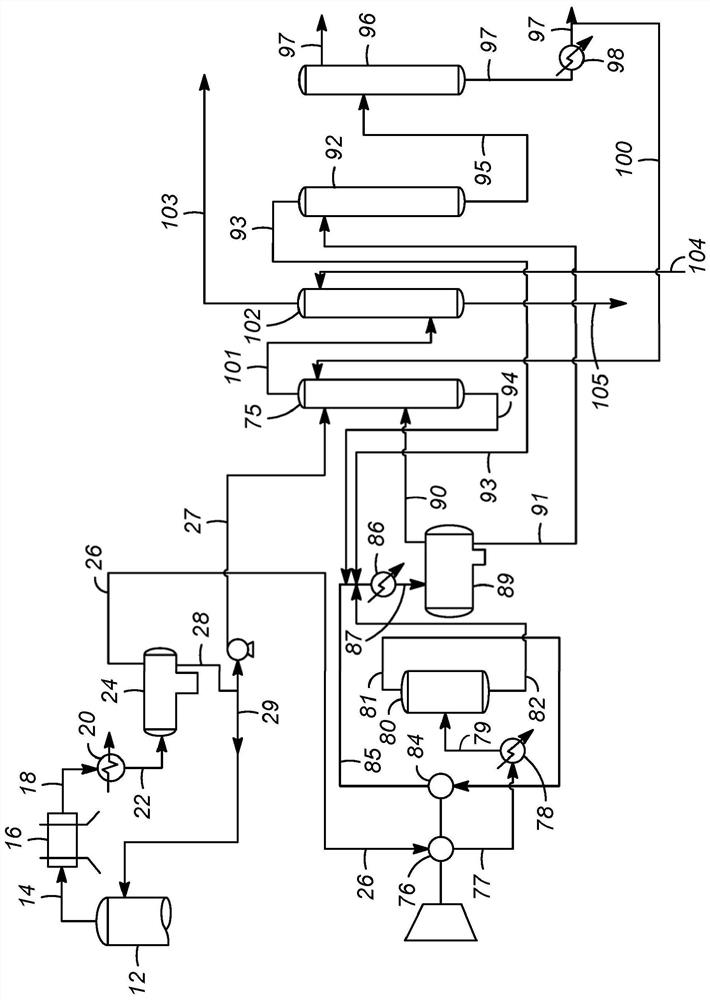

[0044] For existing installations and if the load on the wet gas compressor needs to be reduced due to capacity limitations, it can be done as figure 2 Use a split shell design for the flash tank as shown in . The benefit is to reduce the vapor entering the wet gas compressor while maintaining the same recovery in the gas concentration unit. The amount of propylene removed from the unstabilized gasoline was the same as with a single flash tank but the amount of vapor entering the wet gas compressor was lower as shown in Table 2 below.

[0045] Table 2

[0046] Unsteady gasoline flow, kg / h: 257,508

[0047]

[0048] As shown in the table above, when using split shell or dividing wall tanks, the flow rate to the wet gas compressor is reduced when removing nearly the same amount of propylene from unstabilized gasoline. Also, the overall flow to the wet gas compressor is at a slightly lower temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com