Gas-liquid flow dividing sterile drug liquid packaging

A liquid medicine, gas-liquid technology, applied in the field of pharmaceutical packaging, can solve the problem of not being able to effectively isolate the liquid medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

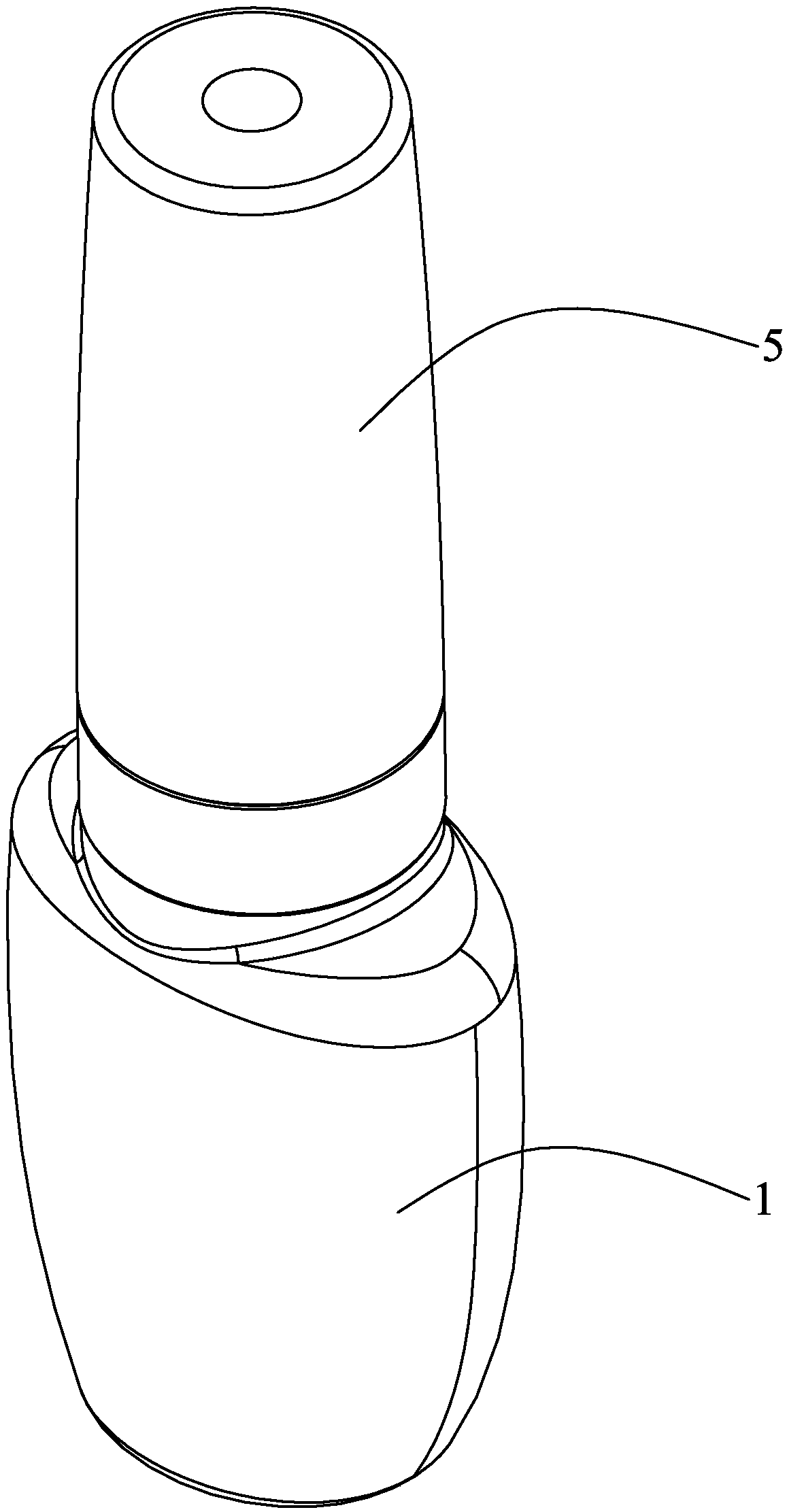

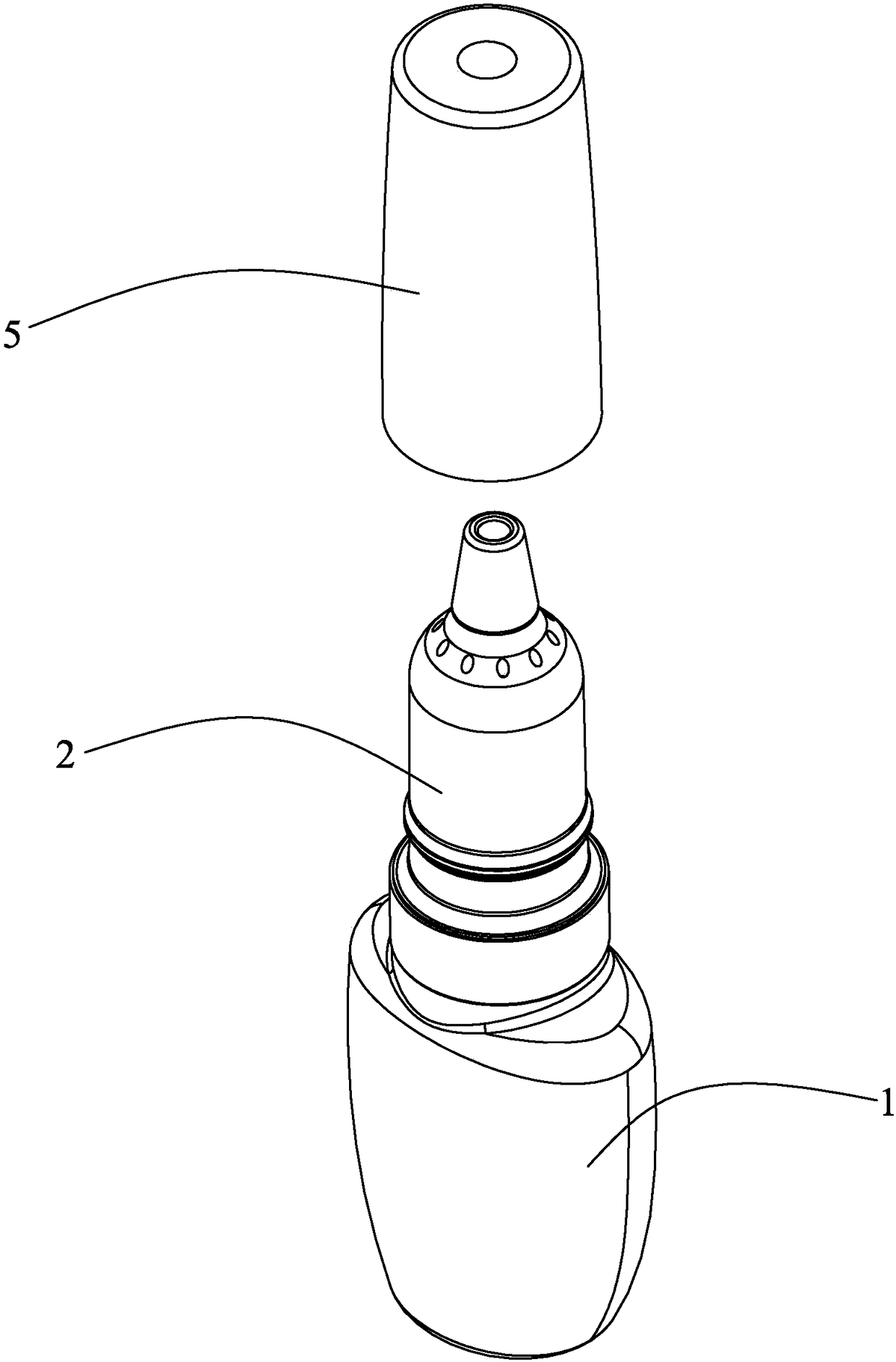

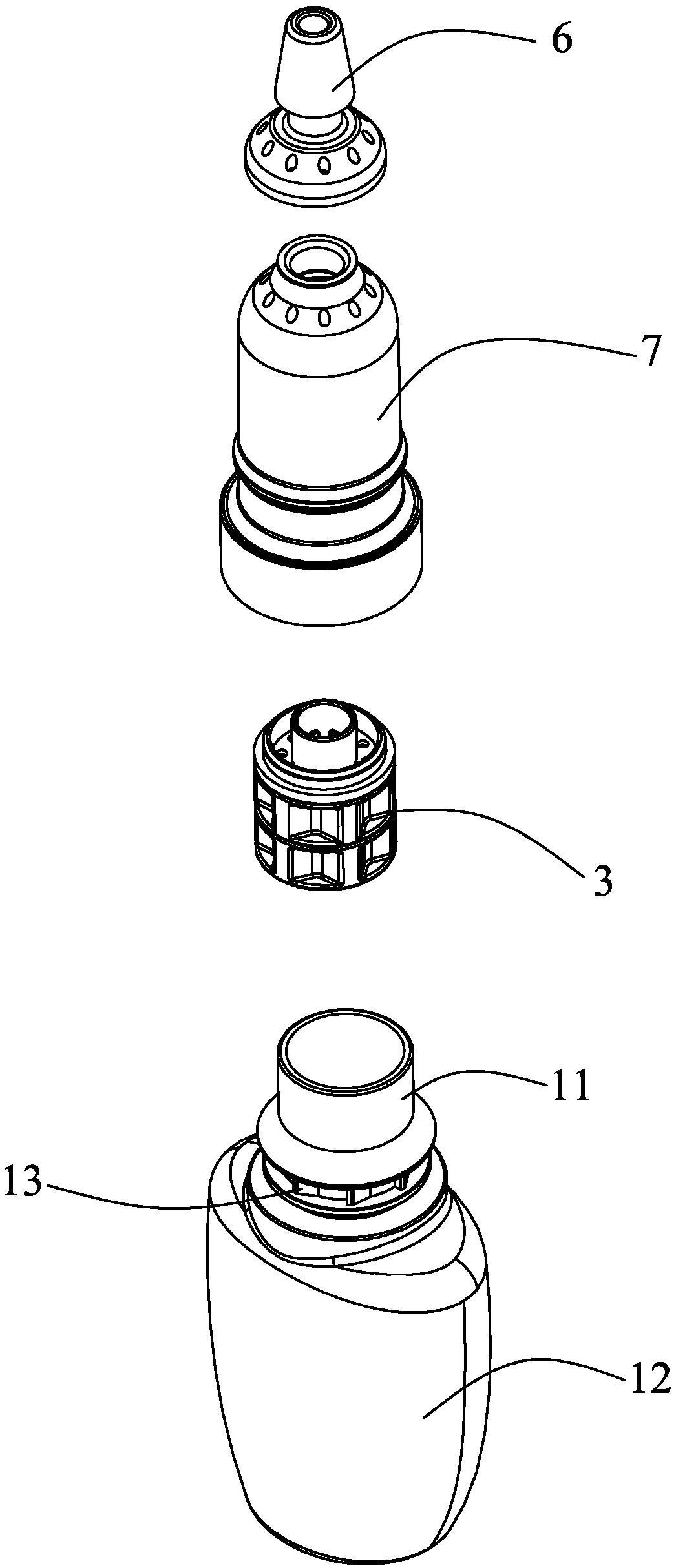

[0024] Such as Figure 1 to Figure 5 As shown, it is a gas-liquid diversion aseptic medicinal liquid packaging 100 according to the present invention, which includes: a self-resetting bottle body 1, a combined bottle stopper system 2 installed above the self-resetting bottle body 1, and a cover set on the combined type Cork protection cap 5 on the cork system 2.

[0025] The self-resetting bottle body 1 is used to load sterile medicinal liquid, and the combined cork system 2 includes a buckle bottle stopper housing 21 fixedly installed on the mouth 11 of the self-resetting bottle body 1 and a snap-on bottle stopper housing 1 filter device 3 and liquid medicine passage check valve 4.

[0026] The filtering device 3 is in the shape of a disc, and the filtering device 3 is provided with a liquid medicine channel 34 and an air filtering channel 35 , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com