Dynamic balancing system and centrifugal machine with dynamic balancing system

A technology of dynamic matching and counterweight blocks, applied in the field of centrifuges, can solve the problems of low trimming efficiency, short moving distance of counterweight blocks, and large influence of the rotating arm, so as to reduce the moving distance by half, save upper surface space, and reduce hydraulic pressure. System simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing:

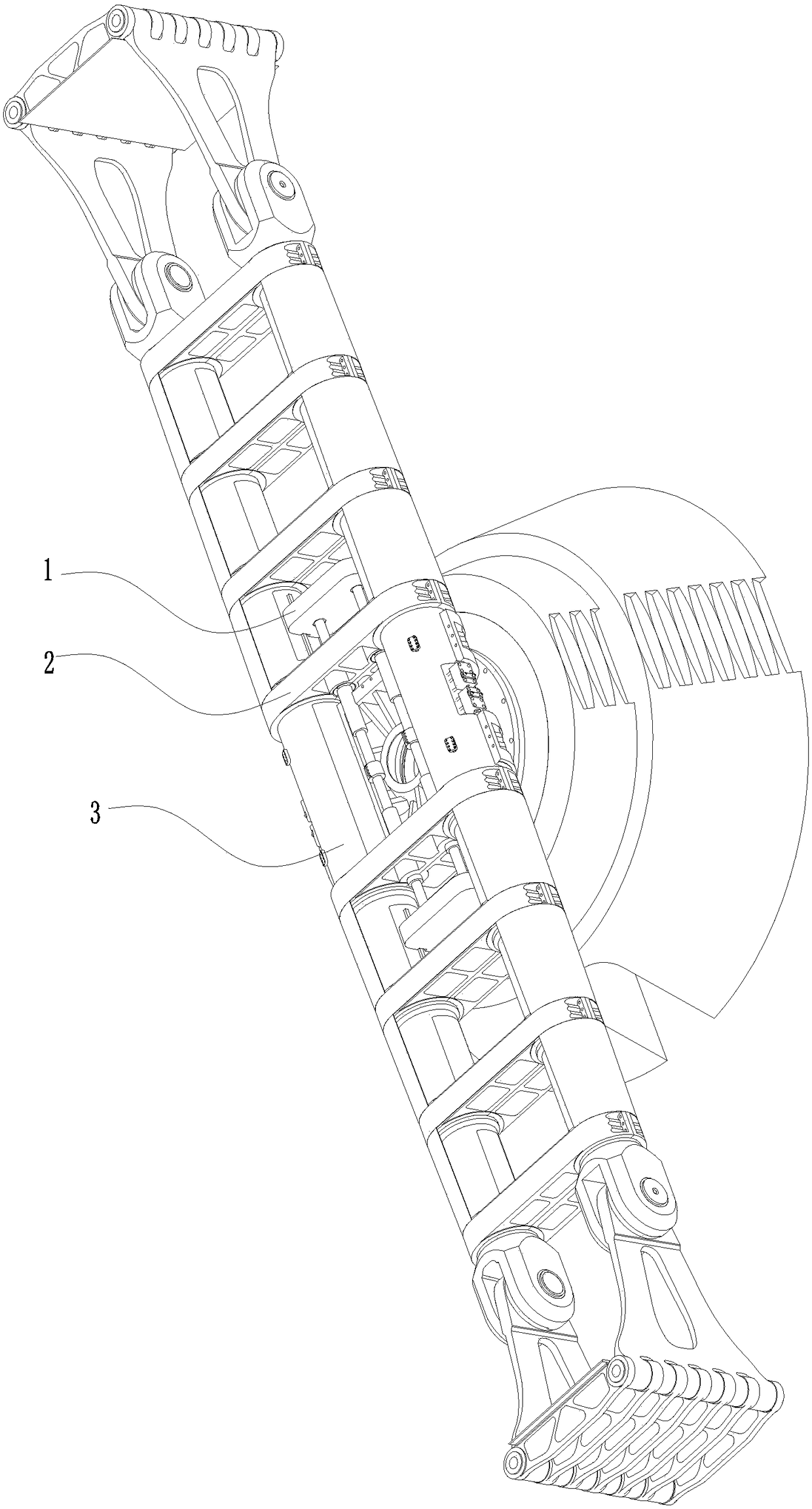

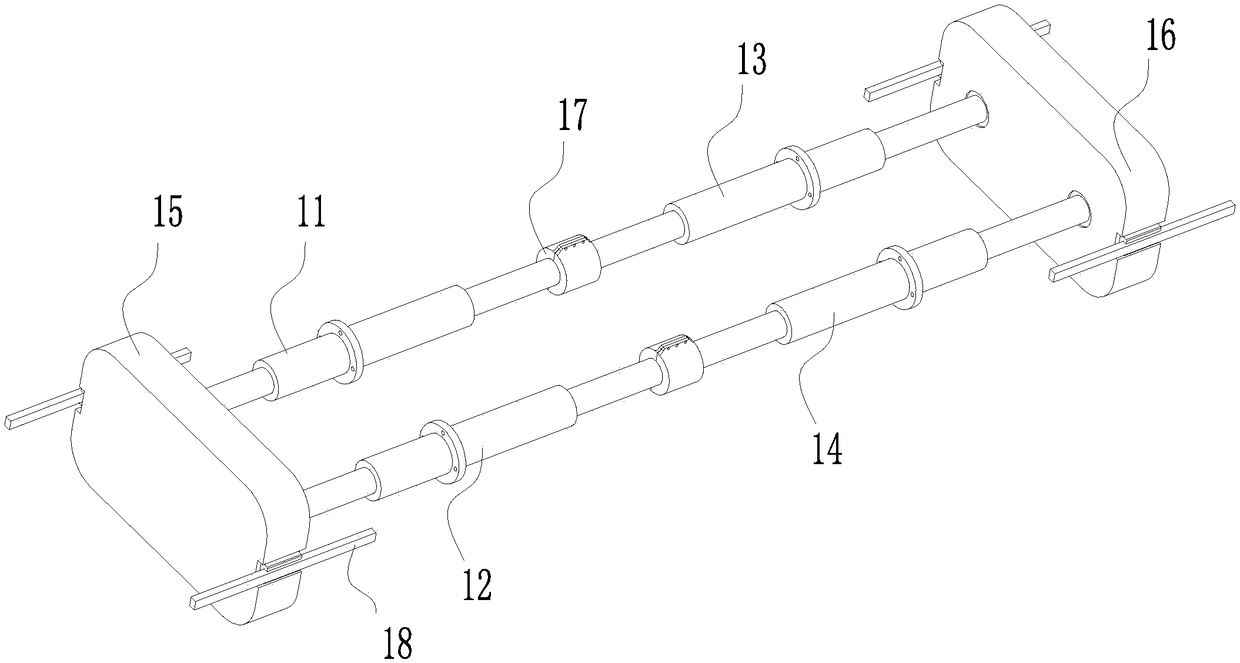

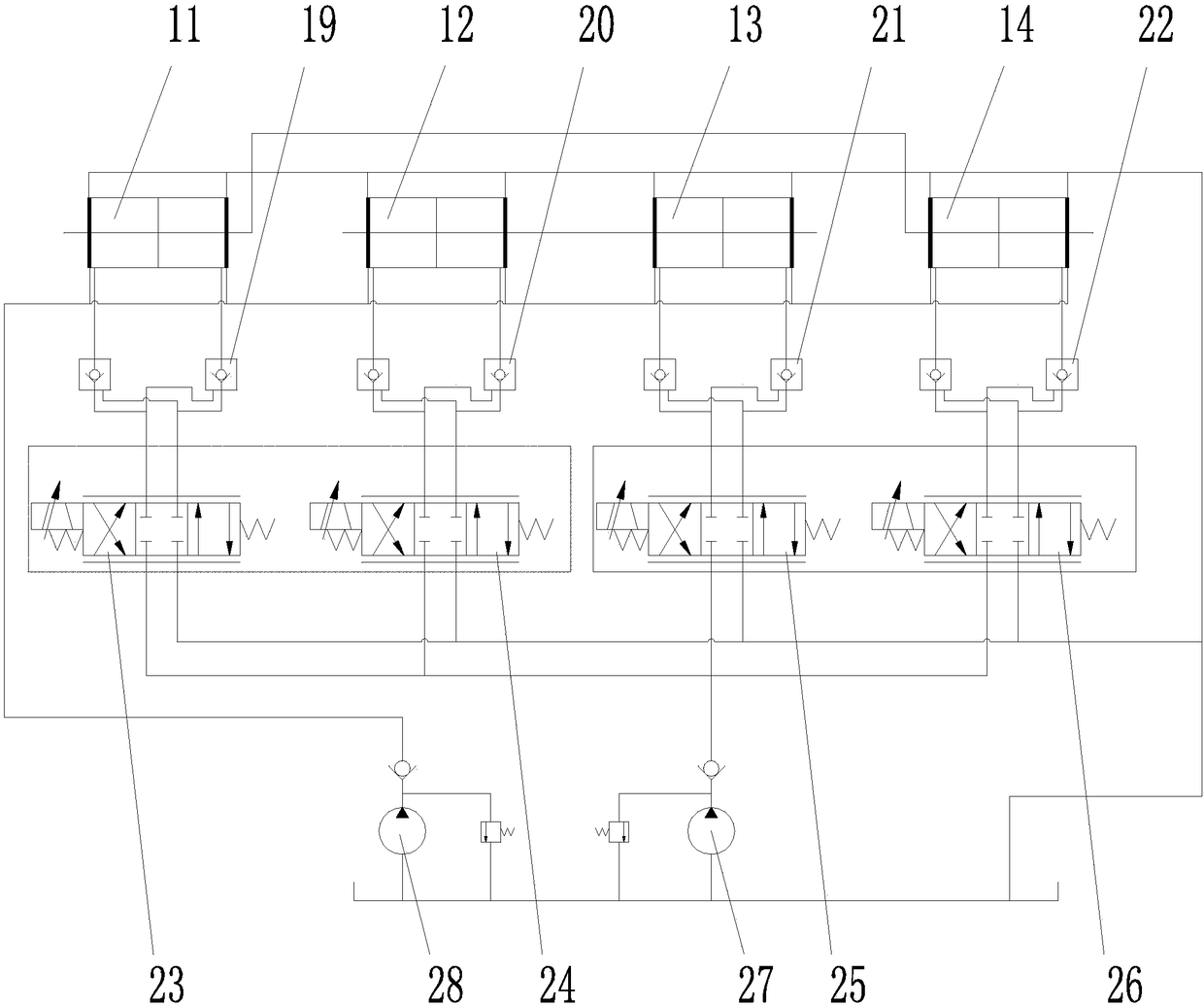

[0042] Such as figure 2 As shown, the dynamic trim system 1 includes:

[0043] The same first counterweight 15 and second counterweight 16, the first counterweight 15 and the second counterweight 16 are respectively placed on both sides of the rotation axis of the rotating device, and the first counterweight 15 and the second counterweight 16 are distributed symmetrically with the rotation axis of the rotating device, and the first counterweight 15 and the second counterweight 16 are rigidly connected;

[0044] The hydraulic cylinder assembly that synchronously pushes the first counterweight 15 and the second counterweight 16 in the same direction through the action of force. A counterweight 15 is connected with a second counterweight 16 .

[0045] During the balance, two mass blocks are moved, and the unbalanced force can be balanced twice that of moving a single mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com