Stereoscopic-vision-based rapid workpiece sorting method and device

A technology of stereo vision and artifacts, which is applied in the field of mail sorting, can solve the problems that the real-time performance cannot meet our needs, reduce the speed of the conveyor belt, and increase the time consumption, etc., so as to reduce dependence, improve real-time performance, and increase the success rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in further detail below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

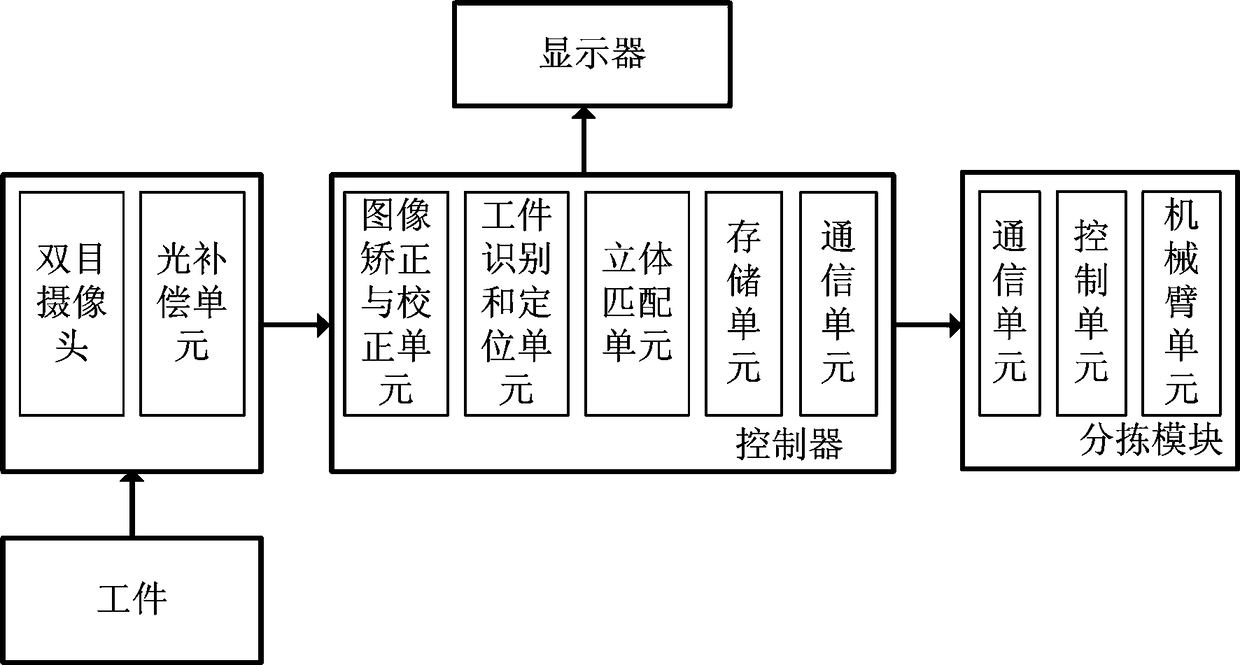

[0059] The invention relates to a rapid workpiece sorting method based on stereo vision, and the method includes the following steps.

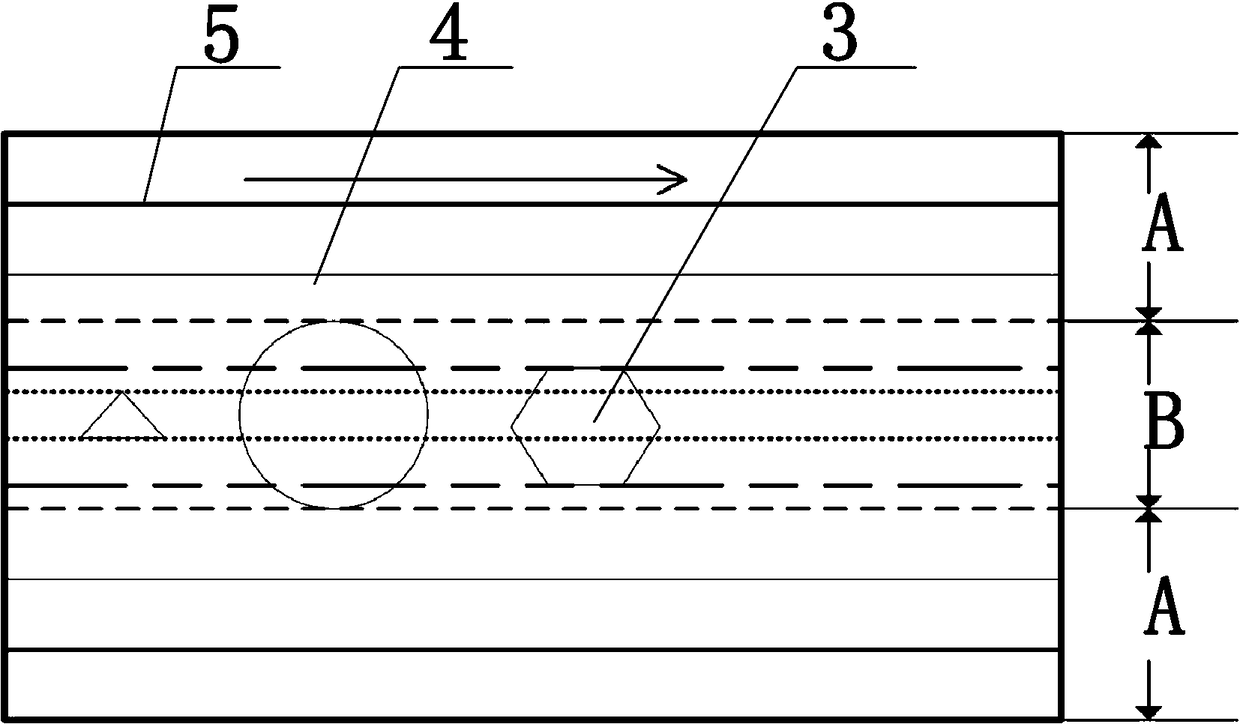

[0060] Step 1: Set the initial frame number count n=1, and set the stereo matching frame number interval M; 1≤n≤M+1;.

[0061] In the present invention, the binocular image collected by the binocular camera 1 is divided into ROIs every M frames, and then stereo matching is performed on the divided regions. n is used to record which frame the current frame belongs to in the M frames, and obtain each frame After the binocular image, the frame count value n=n+1 needs to be updated, until n is M+1, n is reset to 1.

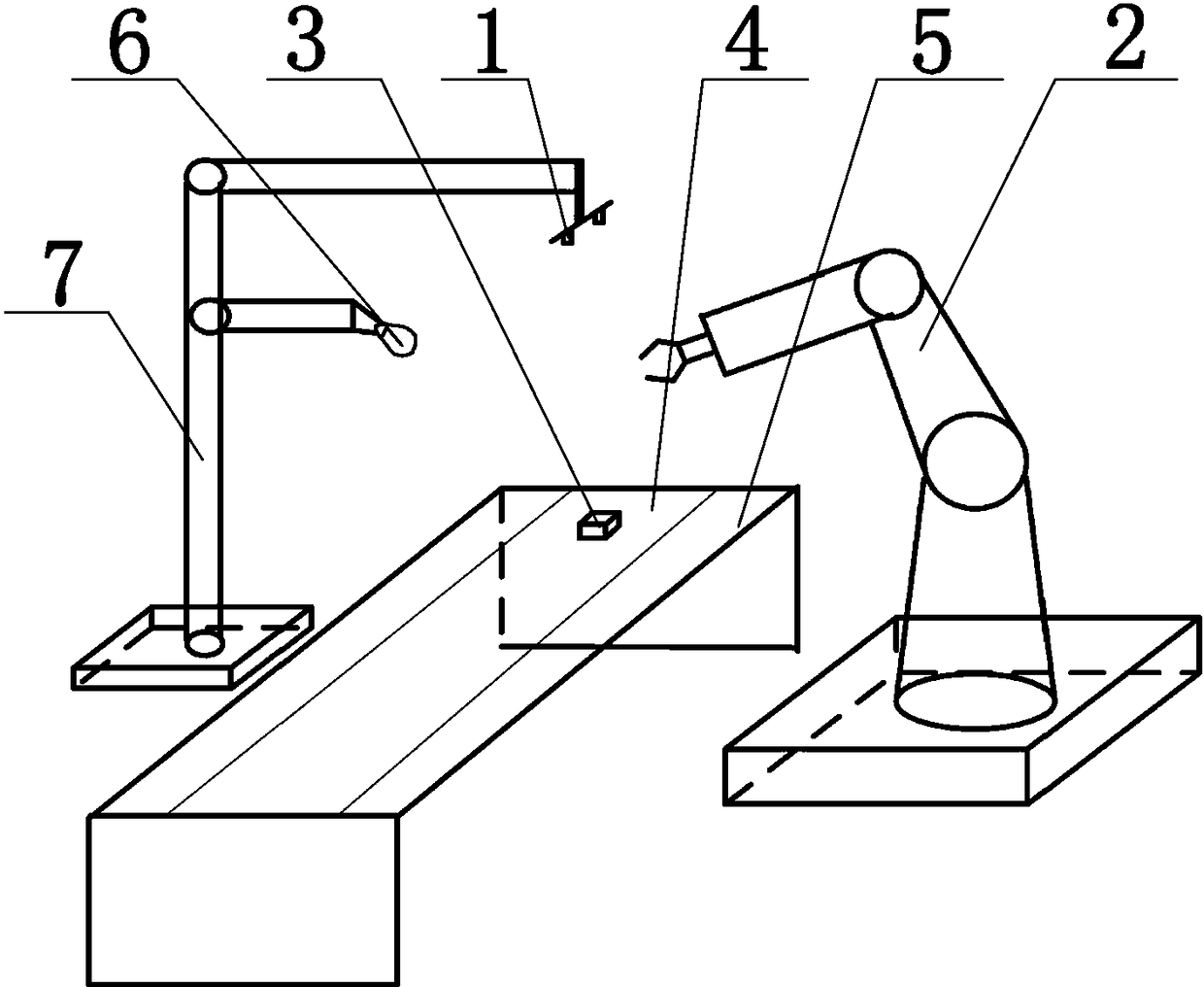

[0062] Step 2: start the sorting, the robotic arm 2 of the sorting module is initialized, and the binocular camera 1 collects the binocular image of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com