Automatic equipment of vertical tubular shoulder injection

An automatic equipment, vertical technology, applied in the direction of tubular goods, other household appliances, household appliances, etc., can solve the problems of low efficiency and difficult labor, and achieve the effect of high efficiency, reasonable structure, and suitable for large-scale promotion and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

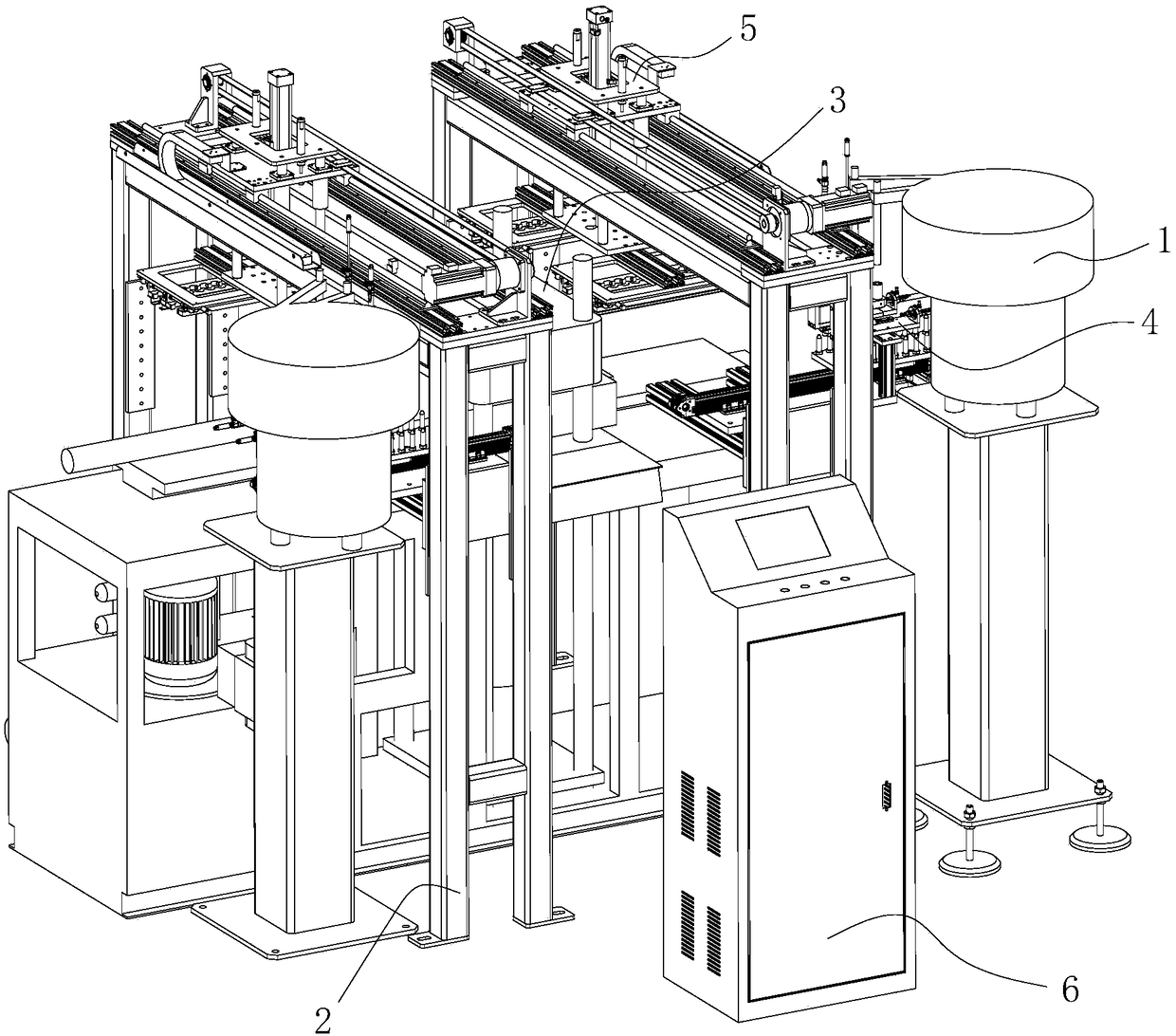

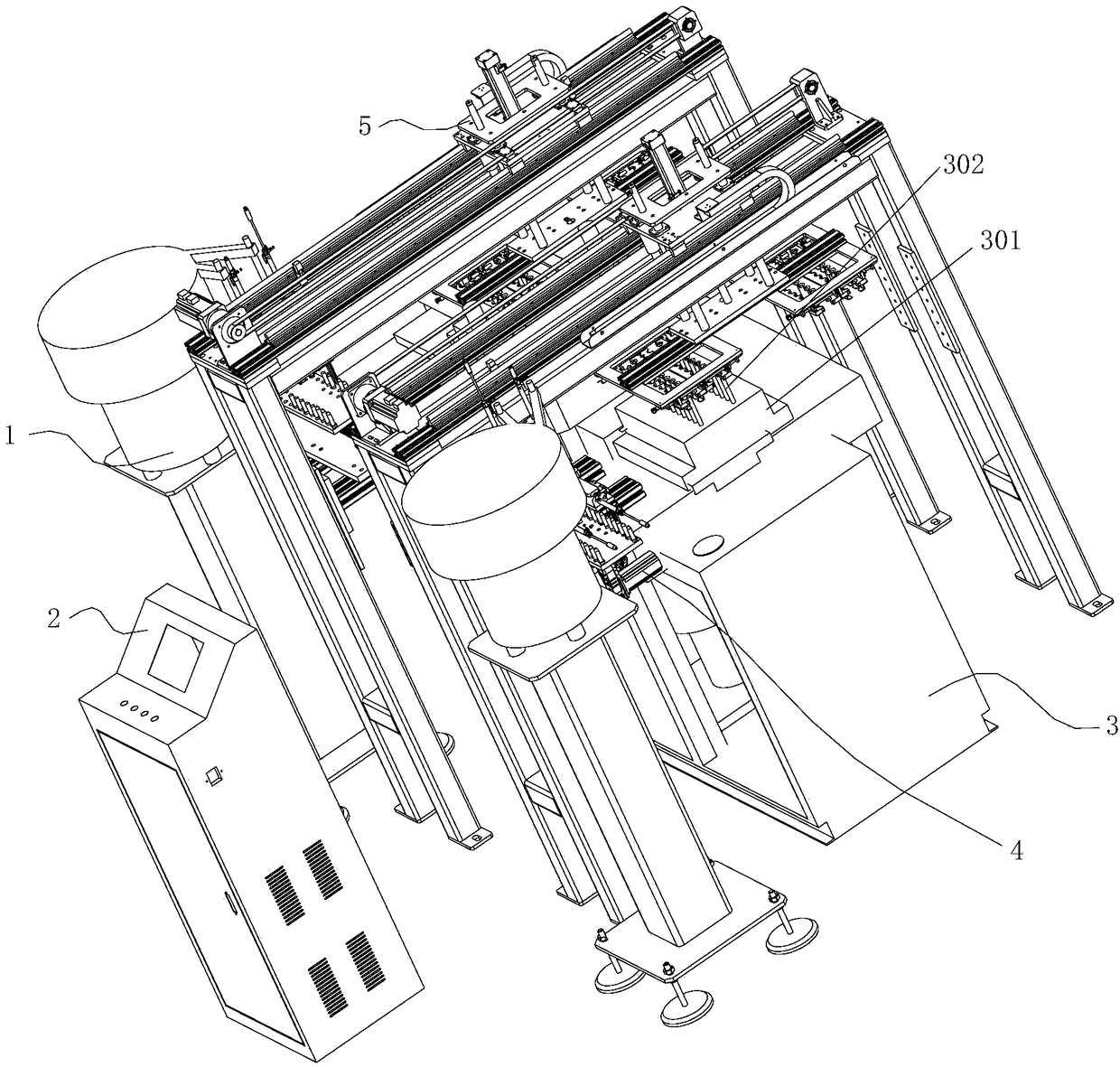

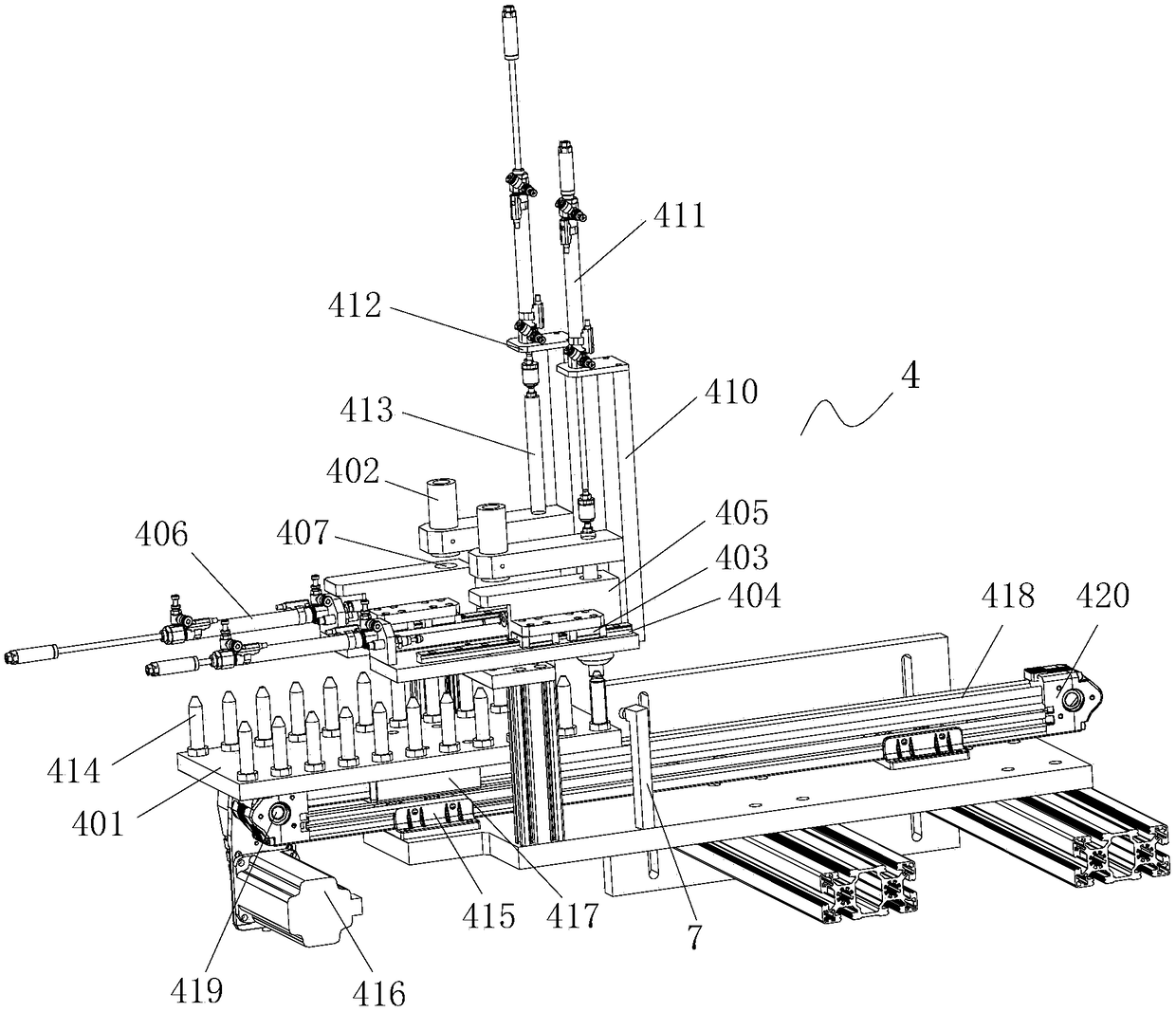

[0041] See figure 1 , figure 2 , Figure 15 with Figure 16 , the present invention is a vertical tubular shoulder injection automation equipment, which has a vertical injection molding machine 3; the mirror images of the two sides of the vertical injection molding machine 3 are provided with a feeding mechanism 1 and a charging mechanism fixedly installed on the frame 2 4 and the translation transfer mechanism 5, there is an electric cabinet 6 sitting on any side around the vertical injection molding machine 3; The discharge plate 401 of the material mechanism 4 is matched; the injection position of the vertical injection molding machine 3 on the frame 2 is fixedly connected with a pneumatic waste handle removal fixture 9 .

[0042] See Figure 13 The feeding mechanism 1 is a vibrating plate feeding mechanism, which includes a vibrating plate 111 installed on the vibrating plate shelf 110; the vibrating plate 111 includes a ring-shaped wall and a hopper connected to the ...

Embodiment 2

[0051] The present invention is a vertical tubular shoulder injection automation equipment, which has a vertical injection molding machine 3; the mirror images on both sides of the vertical injection molding machine 3 are equipped with a feeding mechanism 1 and a charging mechanism 4 fixedly installed on the frame 2 and the translation transport mechanism 5, there is an electric cabinet 6 sitting on any side around the vertical injection molding machine 3; The discharge plate 401 of the mechanism 4 is matched; the injection position of the vertical injection molding machine 3 on the frame 2 is fixedly connected with a pneumatic waste handle removal fixture 9 .

[0052] See Figure 9 to Figure 12 , the feeding mechanism 1 is a lifting feeding device, which includes a storage hopper 101, a feeding mechanism and an upright arrangement of conveying tracks 106; the storage hopper 101 is provided with a bottom surface that is inclined to be provided with a high front end and a low r...

Embodiment 3

[0064] See figure 1 , figure 2 , Figure 15 with Figure 16 , the present invention is a vertical tubular shoulder injection automation equipment, which has a vertical injection molding machine 3; the mirror images of the two sides of the vertical injection molding machine 3 are provided with a feeding mechanism 1 and a charging mechanism fixedly installed on the frame 2 4 and the translation transfer mechanism 5, there is an electric cabinet 6 sitting on any side around the vertical injection molding machine 3; The discharge plate 401 of the material mechanism 4 is matched; the injection position of the vertical injection molding machine 3 on the frame 2 is fixedly connected with a pneumatic waste handle removal fixture 9 .

[0065] Feeding mechanism 1 is a vibrating disk feeding mechanism, which includes a vibrating disk 111 installed on the vibrating disk shelf 110; the vibrating disk 111 includes an annular wall and a hopper connected to the driver; the bottom of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com