Logistics tray and preparation process

A preparation process and pallet technology, which is applied in the field of logistics pallets and its preparation process, can solve problems such as waste of land resources, unsolved problems, unfavorable environmental protection, etc., and achieve the effects of environmental protection, good economic and social benefits, and resource conservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

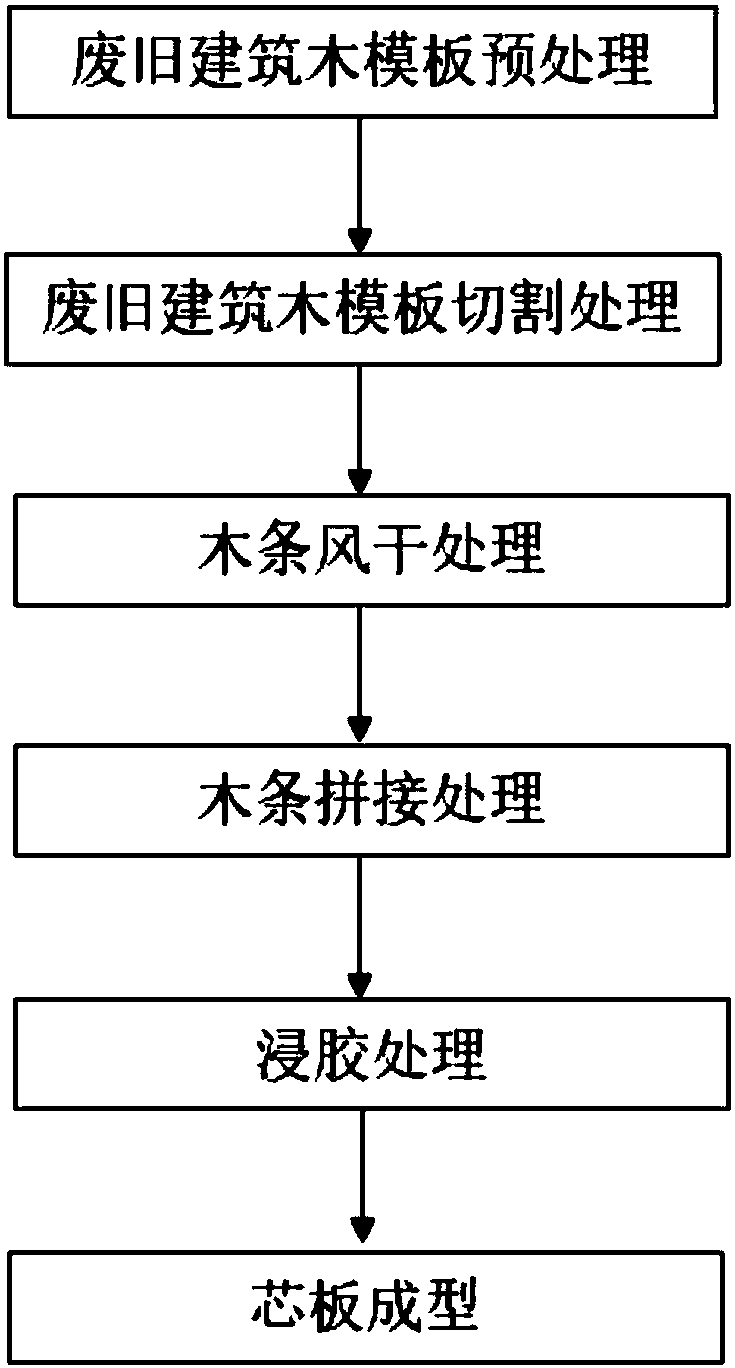

[0032] see figure 1 Shown, the specific embodiment that the present invention provides is as follows:

[0033] A logistics pallet in this embodiment is composed of a plurality of glass-steel composite boards assembled, and the glass-steel composite board includes a core board, and the core board includes a plurality of wooden strips of the same width cut from waste building wood formwork, The width direction of the core board is formed by a plurality of the wooden strips juxtaposed in parallel, and the length direction is formed by splicing a plurality of the wooden strips end to end; the core board also includes a cured resin, and the cured resin is coated on the A plurality of wooden strips are described. In this embodiment, a technical solution for producing logistics pallets by using waste building wooden formwork is proposed, which is beneficial to save limited timber resources, thereby realizing the reuse of waste and old building wooden formwork. In this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com