A kind of ettringite anti-radiation concrete

An ettringite and concrete technology, which is applied in the field of concrete, can solve the problems of affecting the safety effect of nuclear waste solidification, unfavorable resource sustainable utilization, poor construction performance, etc., and achieves convenient implementation, improved radiation protection performance, and good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

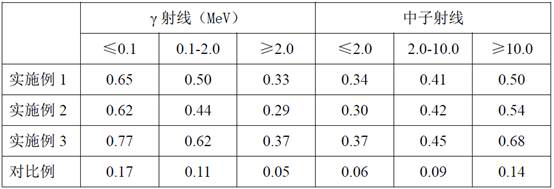

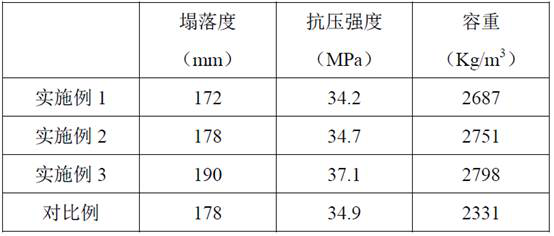

Examples

Embodiment 1

[0019] A kind of ettringite anti-radiation concrete comprises following raw materials and preparation steps in weight fraction:

[0020] (1) Primary hydration: Grind tricalcium aluminate until the specific surface area is 400m 2 / kg; weigh 20 parts of tricalcium aluminate, 20 parts of water, 7 parts of calcium oxide and 7 parts of gypsum, mix evenly, and cure at 30°C for 20 hours at a time;

[0021] (2) Secondary hydration: After the first curing, dry and grind at 60°C, then add 20 parts of tricalcium aluminate, 20 parts of water, 7 parts of calcium oxide and 7 parts of gypsum, mix again, and dry at 30°C for the second time Conservation for 5 days;

[0022] (3) Preparation of fine aggregate: After drying at 40°C, ettringite crystals are obtained; through a 2.36mm sieve, the material under the sieve is ready for use, and the material on the sieve is ettringite fine aggregate;

[0023] (4) Coarse aggregate preparation: Mix and stir 10 parts by weight of high-iron aluminophosph...

Embodiment 2

[0025] A kind of ettringite anti-radiation concrete comprises following raw materials and preparation steps in weight fraction:

[0026] (1) Primary hydration: Grind tricalcium aluminate until the specific surface area is 500m 2 / kg; Weigh 50 parts of tricalcium aluminate, 30 parts of water, 15 parts of calcium oxide and 15 parts of gypsum, mix them evenly, and cure at 55°C for 12 hours;

[0027] (2) Secondary hydration: After the first curing, dry and grind at 40°C, then add 50 parts of tricalcium aluminate, 30 parts of water, 15 parts of calcium oxide and 15 parts of gypsum, mix again, and dry at 55°C for the second time Conservation for 5 days;

[0028] (3) Preparation of fine aggregate: After drying at 60°C, ettringite crystals are obtained; through a 2.36mm sieve, the material under the sieve is ready for use, and the material on the sieve is ettringite fine aggregate;

[0029] (4) Coarse aggregate preparation: Mix and stir 25 parts by weight of high-iron aluminophospha...

Embodiment 3

[0031] A kind of ettringite anti-radiation concrete comprises following raw materials and preparation steps in weight fraction:

[0032] (1) Primary hydration: Grind tricalcium aluminate until the specific surface area is 450m 2 / kg; Weigh 40 parts of tricalcium aluminate, 25 parts of water, 12 parts of calcium oxide and 10 parts of gypsum, mix them evenly, and cure at 40°C for 15 hours at a time;

[0033] (2) Secondary hydration: After the first curing, dry and grind at 50°C, then add 40 parts of tricalcium aluminate, 25 parts of water, 12 parts of calcium oxide and 10 parts of gypsum, mix again, and dry at 45°C for the second time 4 days of maintenance;

[0034] (3) Preparation of fine aggregate: After drying at 50°C, ettringite crystals are obtained; through a 2.36mm sieve, the material under the sieve is set aside, and the material on the sieve is ettringite fine aggregate;

[0035] (4) Coarse aggregate preparation: Mix and stir 20 parts by weight of high-iron aluminopho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com