Vertical steaming and stir-frying cauldron

A technology for steaming and frying, which is applied in the production of fat, fat oil/fat, etc., can solve the problems of full storage of the steaming and frying chamber, tripping and shutdown, and large friction factor of oil, so as to achieve controllable material distribution and simple structure design. , good effect of steaming and frying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

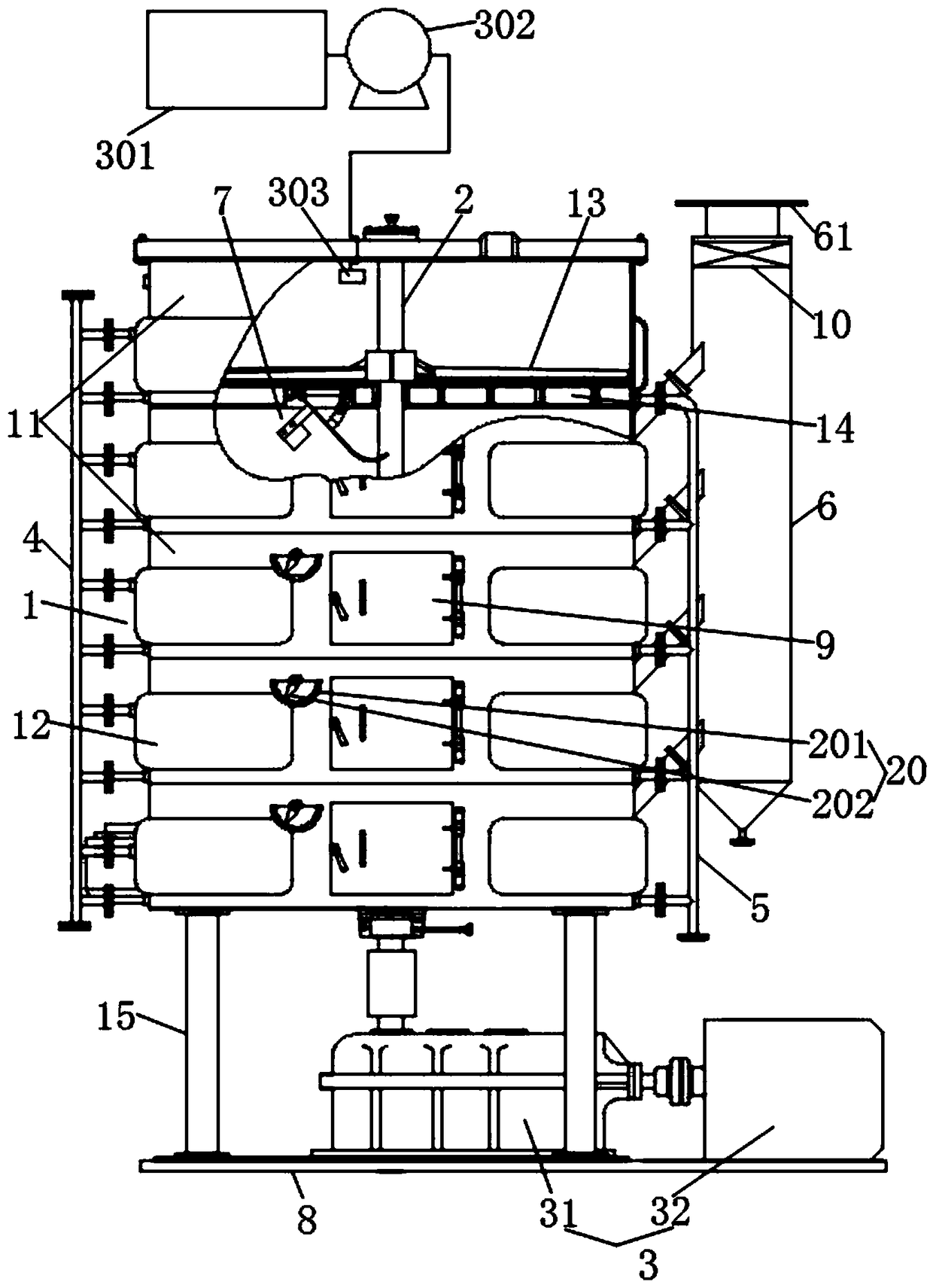

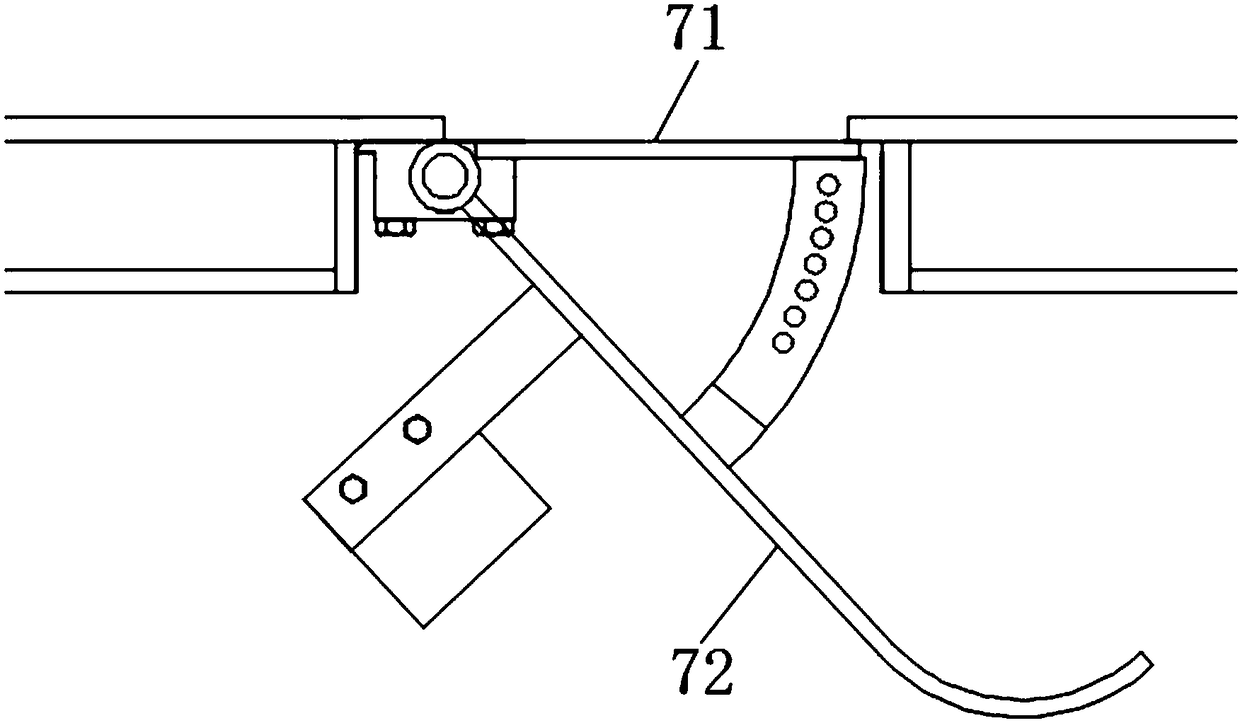

[0038] Example: such as figure 1 As shown, the vertical steaming and frying pan of the present embodiment includes a cylinder body 1, a rotating shaft 2, a driving mechanism 3, a steam main pipe 4, a exhaust steam main pipe 5 and an exhaust pipe 6;

[0039] The above-mentioned cylinder 1 is coaxially provided with multi-layer mutually independent cylindrical steaming and frying chambers 11 from top to bottom, and the upper end of the above-mentioned cylinder 1 is provided with a feeding port communicated with the above-mentioned steaming and frying chambers 11 on the uppermost floor, and the lower end is provided with There is a discharge port communicated with the above-mentioned steaming and frying chamber 11 on the lowermost floor;

[0040] The outer wall of the above-mentioned cylinder 1 is provided with a steam outer chamber 12 corresponding to the position of each of the above-mentioned steaming and frying chambers 11;

[0041] Each of the above-mentioned steam outer ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com