Immerged electrolysis ozone generator

A technology of ozone generator and cathode conduction, applied in the electrolysis process, electrolysis components, etc., can solve the problems of cumbersome installation and replacement, reduced service life of the generator, inconvenience for users, etc., and achieve easy installation and replacement operation, simple and practical structure , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0017] The specific embodiment: the specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

Embodiment

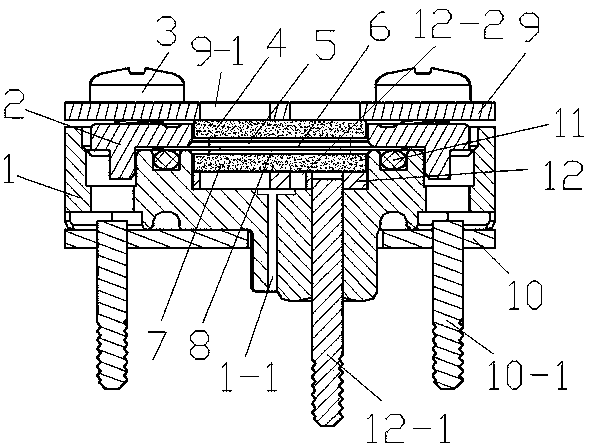

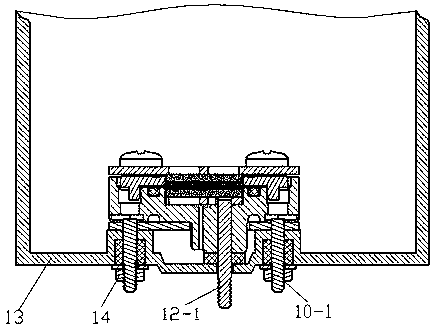

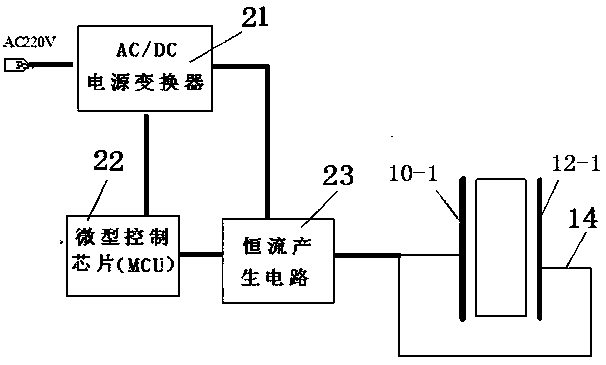

[0018] Embodiment: a kind of submerged electrolytic ozone generator (referring to figure 1 , figure 2 ), which includes a cathode structure and an anode structure, the cathode structure includes a lower reinforced titanium plate 10, the lower reinforced titanium plate 10 is connected with an anode conductive stud 10-1, the lower reinforced titanium plate 10 is provided with a cathode frame body 1, and the cathode frame The body 1 is processed with a cathode water guide and air guide hole 1-1, the cathode frame body 1 is embedded with a cathode conduction plate 12, the cathode conduction plate 12 is processed with a water guide and air guide hole 12-2, and the cathode conduction plate 12 is connected with a cathode conduction screw. Column 12-1, the cathode conductive plate 12 is provided with a cathode microporous titanium plate 7, the cathode microporous titanium plate 7 is provided with a cathode catalyst layer 8, the cathode catalyst layer 8 is provided with a proton excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com