Last-stage electric field rapping control and system of electric dust removal system

A technology of electrostatic precipitator and electric field, applied in the field of final electric field rapping control system, can solve the problems of serious secondary dust emission, achieve the effect of improving adsorption capacity, enhancing adsorption capacity, and reducing secondary dust emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

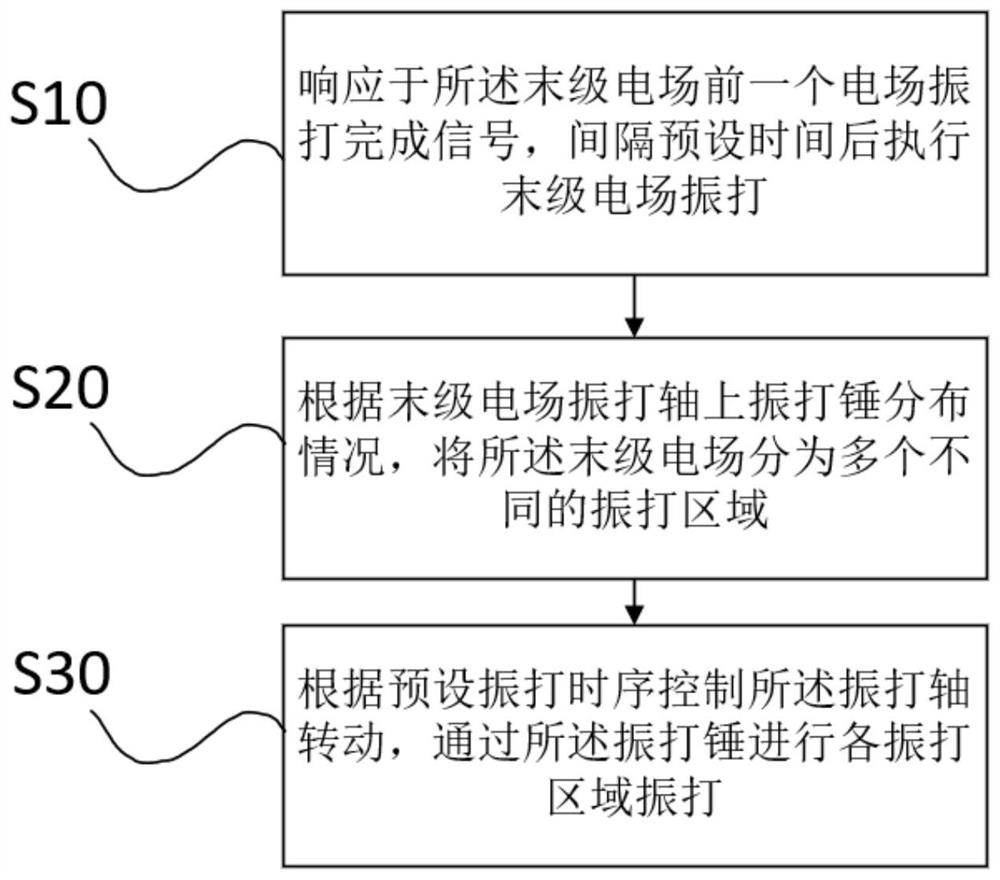

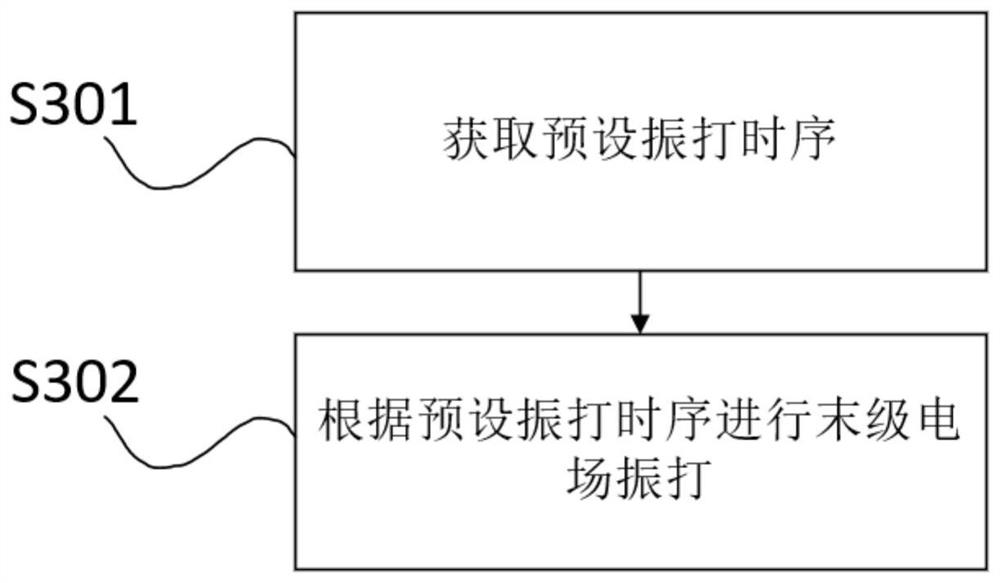

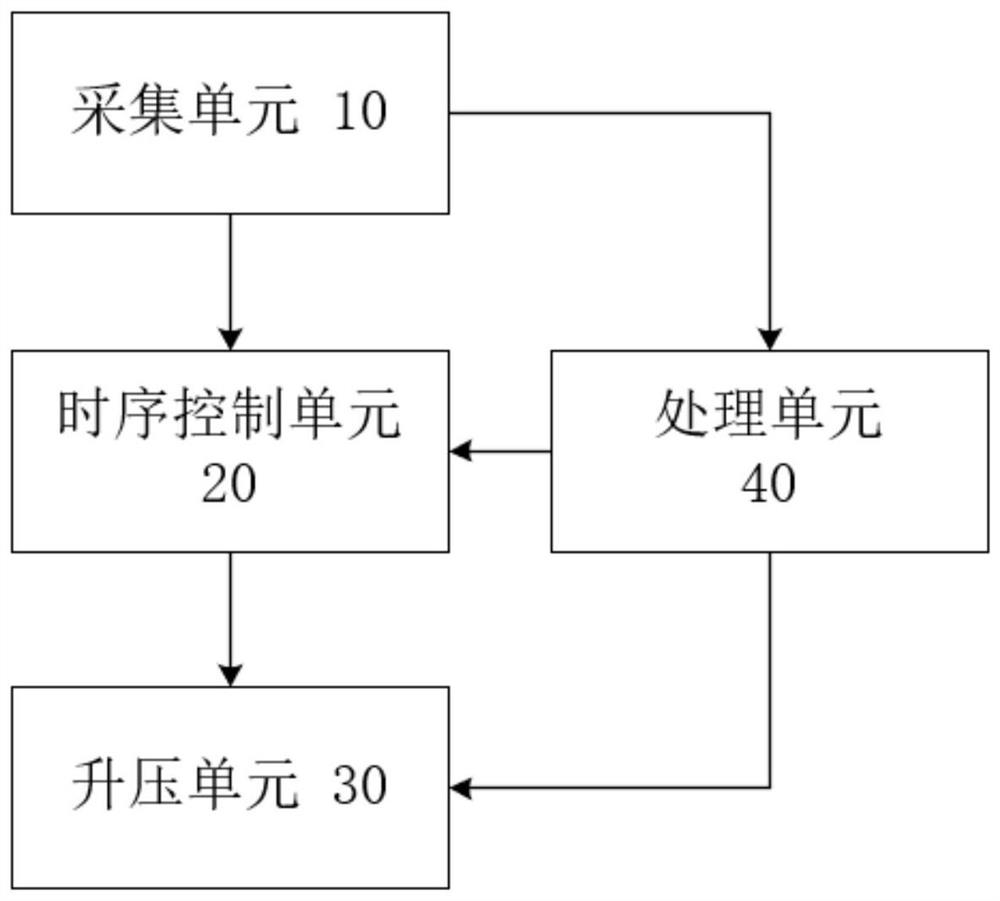

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0024] In the prior art, the electrostatic precipitator mainly charges the dust, and then absorbs the charged dust to the dust collecting plate through the anisotropic electric field of the dust collecting electric field. The hammer vibrates the dust collection plate, so that the dust accumulated on the dust collection plate is shaken off, and the centralized treatment of dust is realized. Along the flue gas flow direction, there are multiple electric fields in the electrostatic precipitator system to process dust step by step. In the traditional control method, each electric field is numbered from the inlet end to the outlet end of the electrostatic precipitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com