Composite protective structure against blast impact

A composite protective structure, explosion impact technology, applied in earthquake resistance, building components, protective buildings/shelter, etc., can solve the problems of secondary damage protection structure, difficult to repair quickly, easy to crack, etc., to eliminate explosion shock collapse. phenomenon, the effect of improving the structural ductility and improving the resistance level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

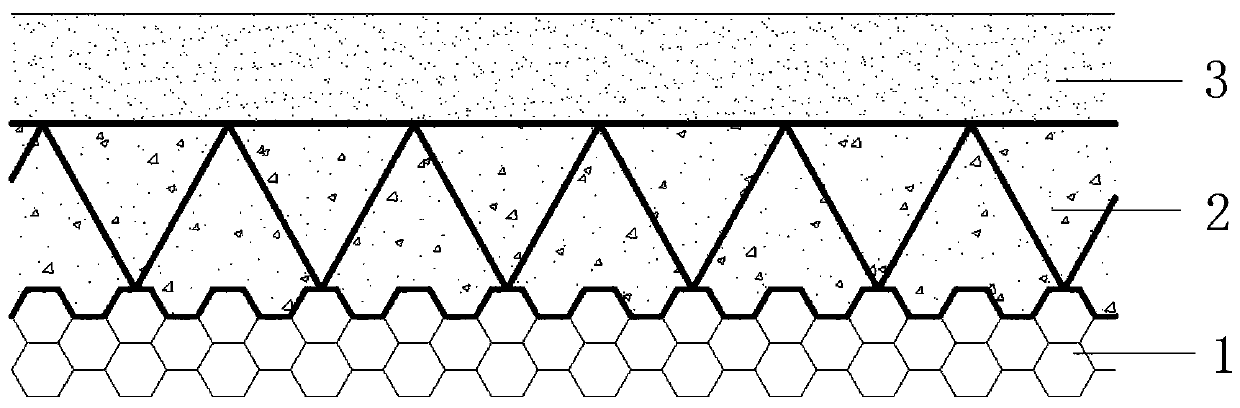

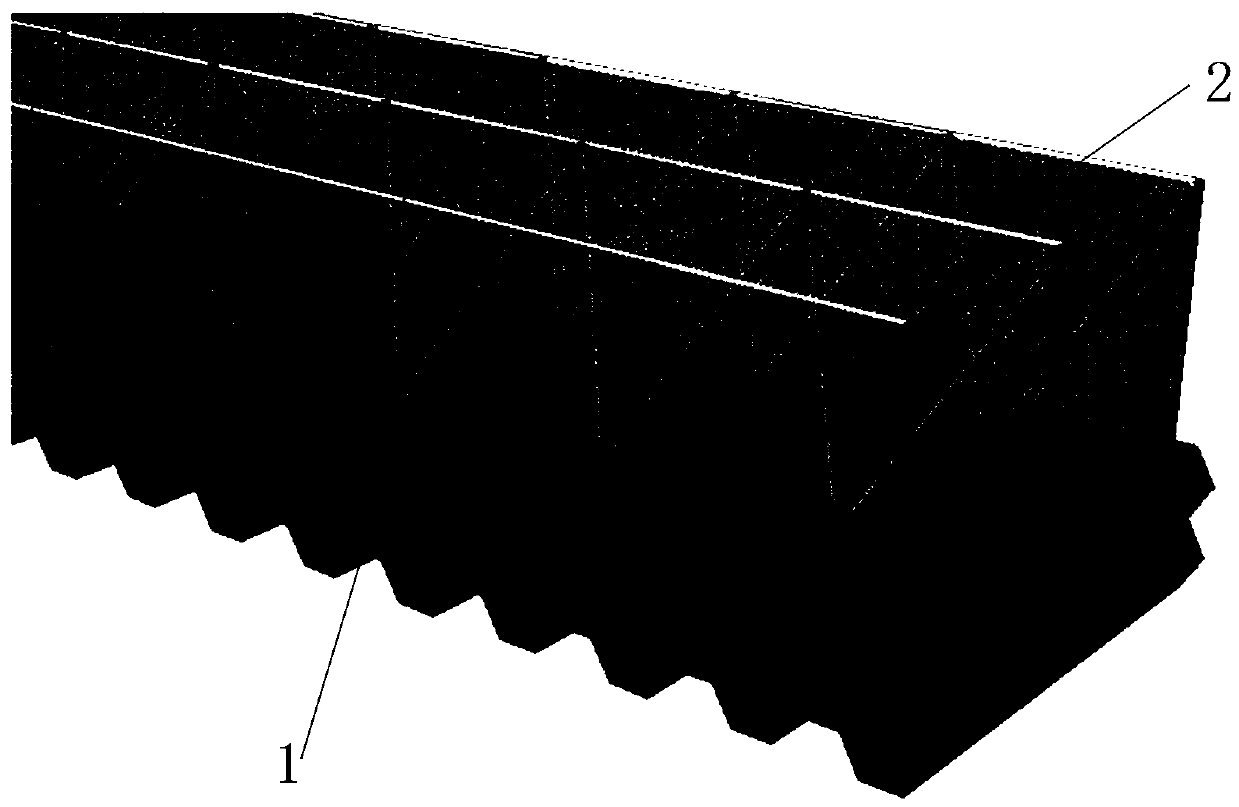

[0029] A novel point truss honeycomb concrete composite protective structure comprises an energy absorption layer 3 , a truss-type compressive layer 2 and a honeycomb-type tensile layer 1 .

[0030] The honeycomb tensile layer 1 includes a honeycomb structure, and the honeycomb structure is filled with concrete to form the bottom formwork of the structure.

[0031] The truss-type compression layer 2 includes a truss structure; the truss structure is welded on the honeycomb structure to form an integral formwork structure; concrete is poured above the honeycomb structure to a height of 15cm above the top rod of the truss structure.

[0032] An energy-absorbing layer 3 is laid on the structural surface layer of the truss-type compression layer 2 .

[0033] In specific implementation, the energy absorbing layer is made of foamed aluminum material with a thickness of 20mm.

[0034] The truss-type compressive layer is a lattice truss structure, the truss height is 120mm, the steel...

Embodiment 2

[0037] A novel point truss honeycomb concrete composite protective structure comprises an energy absorption layer 3 , a truss-type compressive layer 2 and a honeycomb-type tensile layer 1 .

[0038] The honeycomb tensile layer 1 includes a honeycomb structure, and the honeycomb structure is filled with concrete to form the bottom formwork of the structure.

[0039] The truss-type compression layer 2 includes a truss structure; the truss structure is welded on the honeycomb structure to form an integral formwork structure; concrete is poured above the honeycomb structure to a height of 15cm above the top rod of the truss structure.

[0040] An energy-absorbing layer 3 is laid on the structural surface layer of the truss-type compression layer 2 .

[0041] In the specific implementation, the energy-absorbing layer is made of foamed concrete material with a thickness of 10 mm.

[0042] The truss-type compressive layer is a lattice truss structure, the truss height is 150mm, the ...

Embodiment 3

[0045] A novel point truss honeycomb concrete composite protective structure comprises an energy absorption layer 3 , a truss-type compressive layer 2 and a honeycomb-type tensile layer 1 .

[0046] The honeycomb tensile layer 1 includes a honeycomb structure, and the honeycomb structure is filled with concrete to form the bottom formwork of the structure.

[0047] The truss-type compression layer 2 includes a truss structure; the truss structure is welded on the honeycomb structure to form an integral formwork structure; concrete is poured above the honeycomb structure to a height of 15cm above the top rod of the truss structure.

[0048] An energy-absorbing layer 3 is laid on the structural surface layer of the truss-type compression layer 2 .

[0049] During the specific implementation, the energy-absorbing layer is made of foamed concrete material with a thickness of 50mm.

[0050] The truss-type compressive layer is a point truss structure, the height of the point truss ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com