Explosion-proof valve for engine

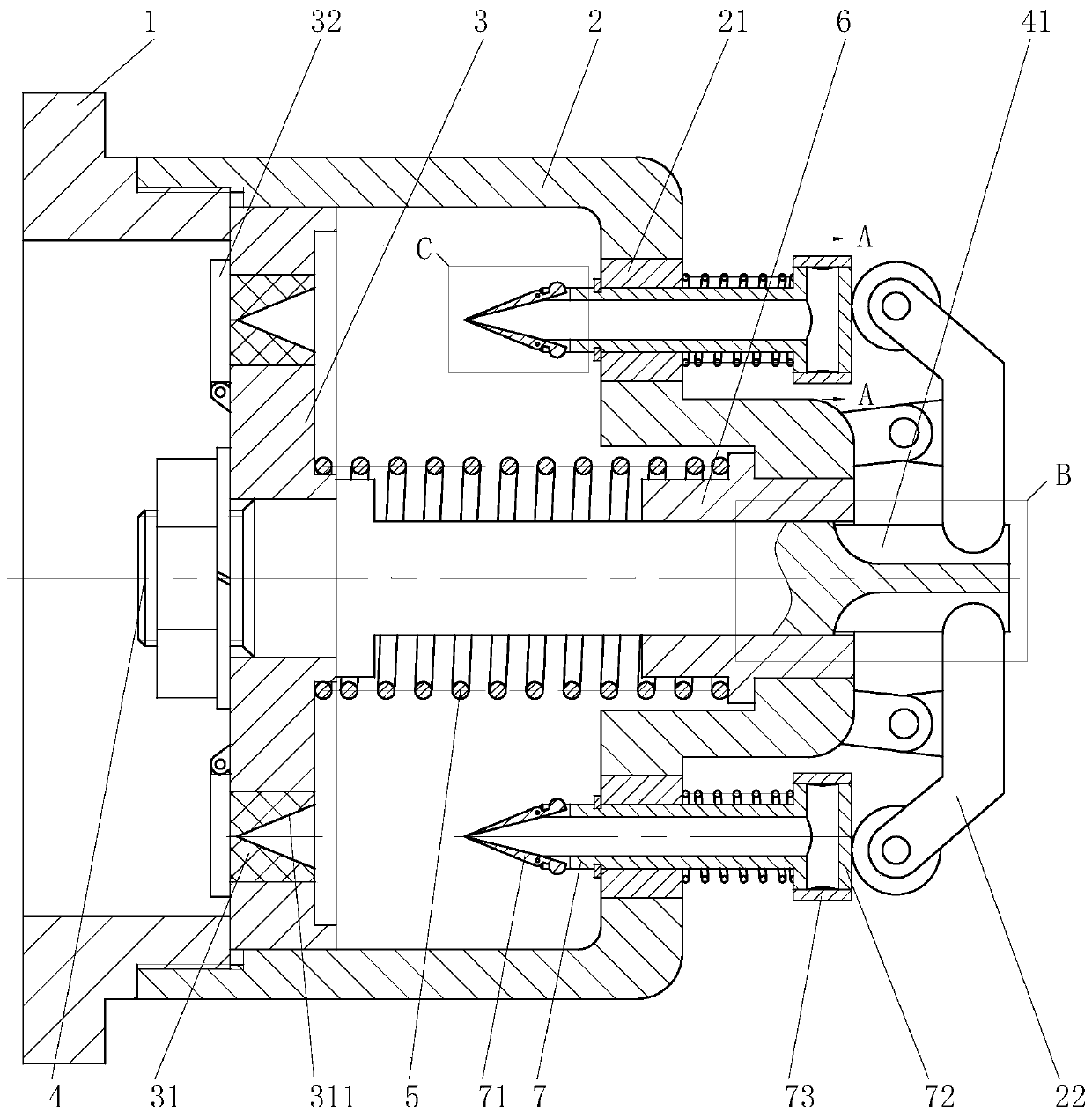

An explosion-proof valve and engine technology, applied to engine components, machines/engines, valve devices, etc., can solve the problems of insufficient gas discharge, valve core wear, etc., to shorten the time and increase the reaction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

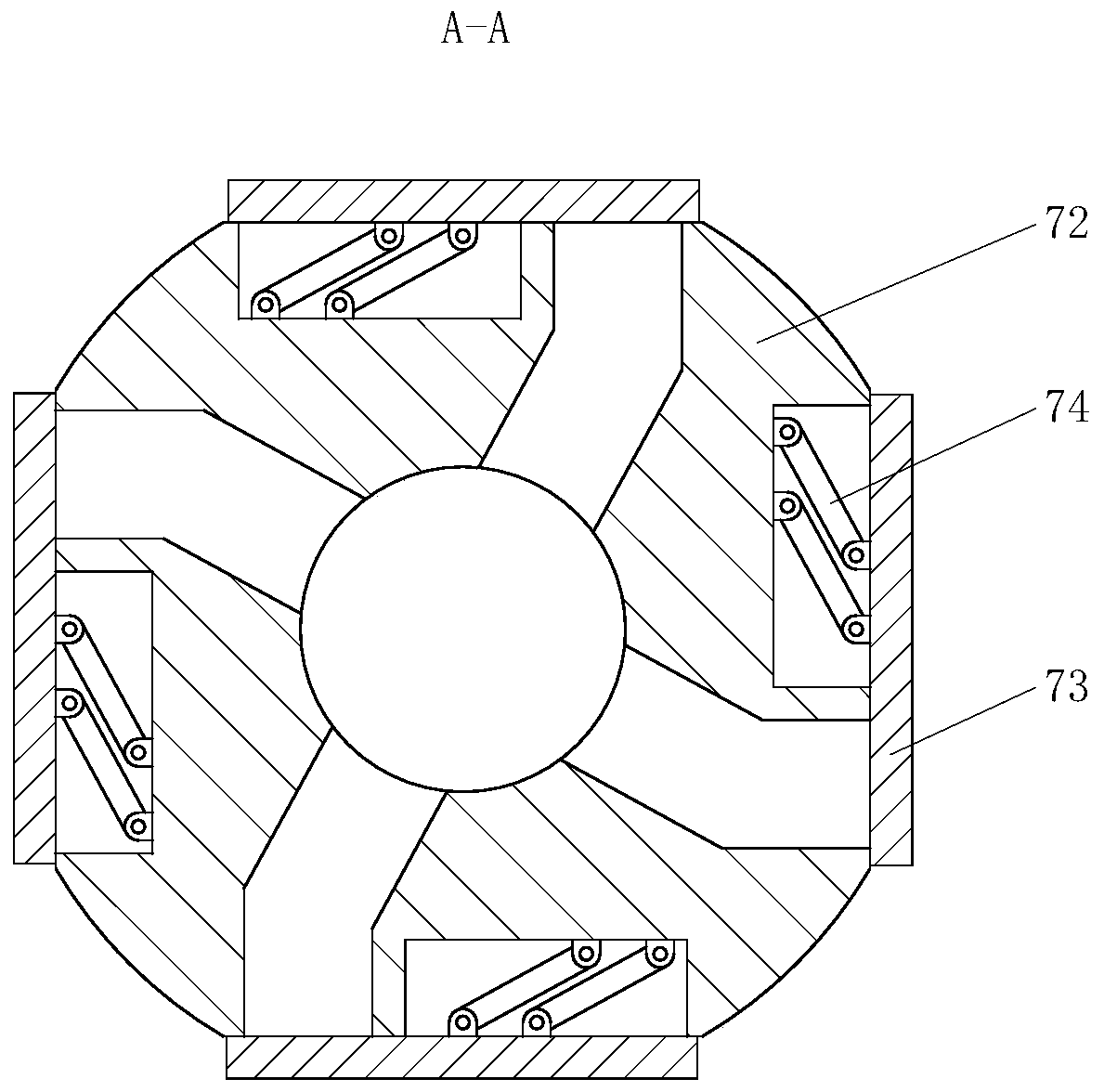

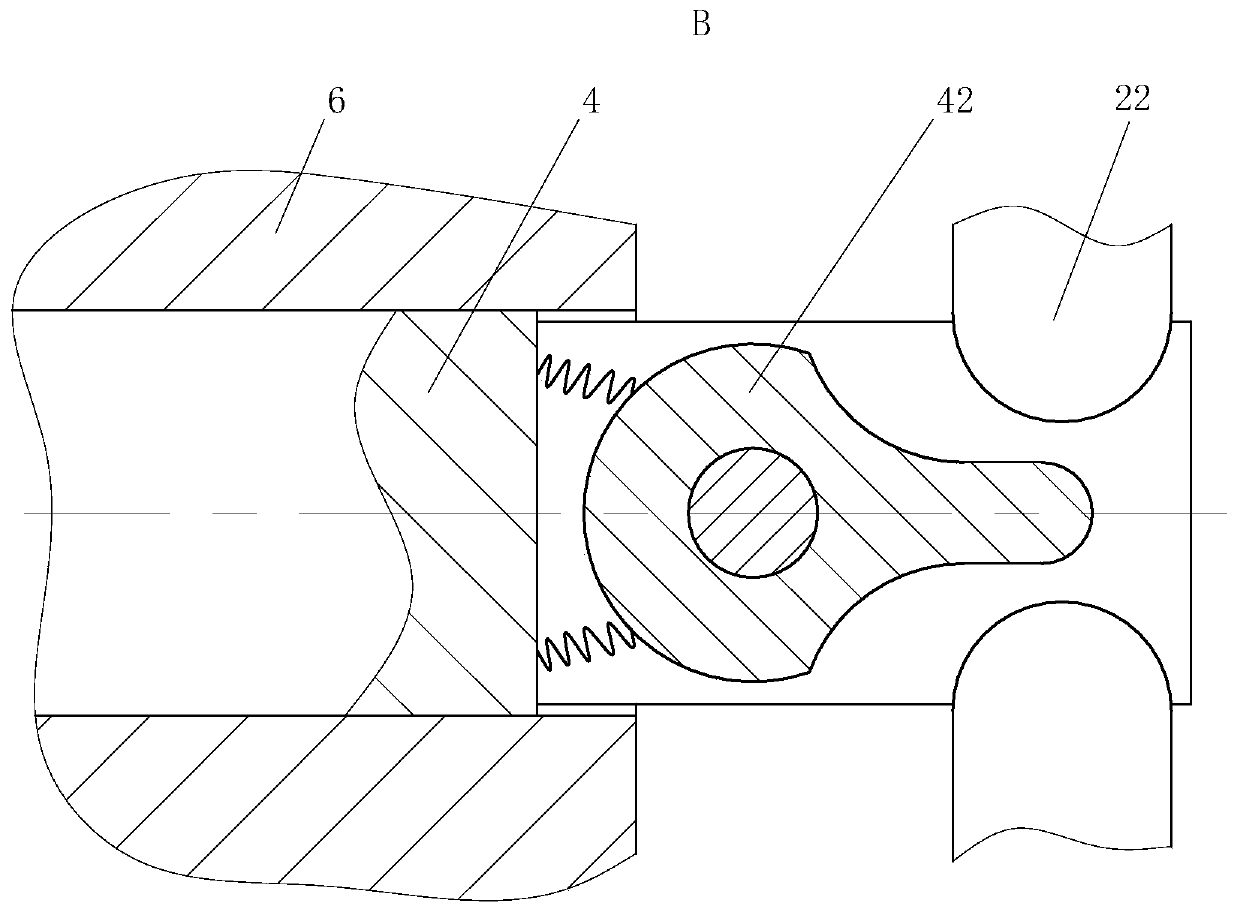

[0025] As an embodiment of the present invention, the chute 41 is a rectangular slot, and a swing block 42 is installed in the chute 41 through a rotating shaft; Two sets of springs are arranged symmetrically between the arc surface and the chute 41, and the swing block 42 is driven by the main shaft 4 to move, so that the arc surface of the swing block 42 squeezes the swing rod 22; when working, the high-pressure gas pushes the valve core 3 to move, and the valve core 3 Drive the main shaft 4 to move, the main shaft 4 drives the swing block 42 to move, the two arc surfaces at one end of the swing block 42 squeeze the other end of the swing rod 22, when the pressure of the swing rod 22 on the two arc surfaces is different, the swing Block 42 automatically adjusts the swing angle around the rotating shaft to ensure that the eccentric moment on the two arc surfaces will not act on the main shaft 4 .

[0026] As an embodiment of the present invention, a dust shield 73 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com