A method for controlling the power of an electric wall-hung boiler

A power control and electric wall technology, applied in lighting and heating equipment, fluid heaters, etc., can solve the problems of shortening the service life of electric hanging furnaces, having no power control method, and increasing the burden on the power grid, so as to achieve a perfect power control scheme and control The effect of intelligent system and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

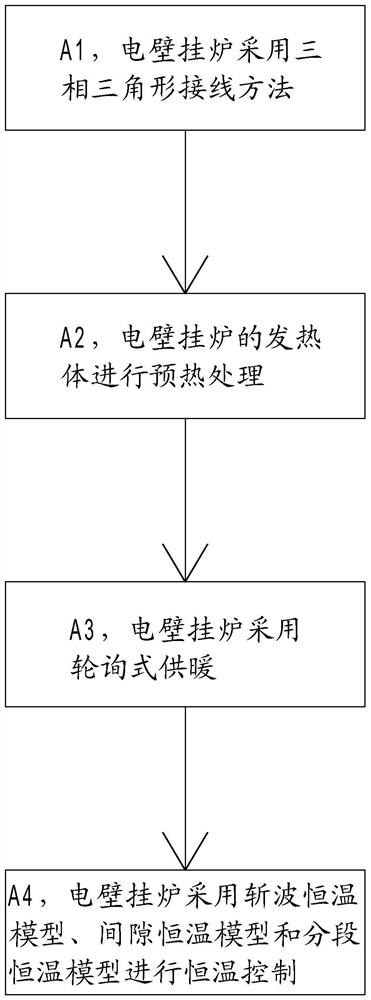

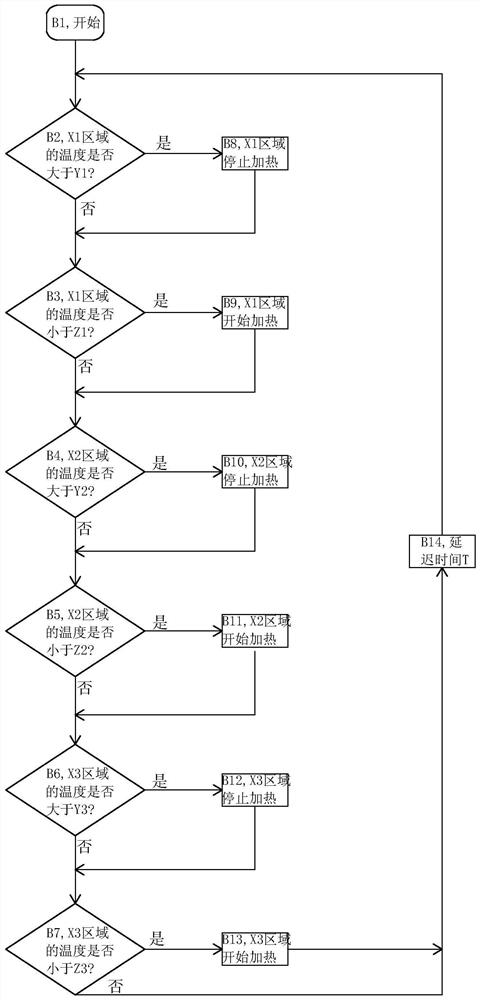

[0037] figure 1 is a flowchart of the present invention, figure 2 is the flow chart of polling heating, such as figure 1 and figure 2 As shown, a power control method for an electric wall-hung boiler includes the following steps:

[0038] A1, the electric wall-hung boiler adopts the three-phase delta connection method;

[0039] A2, the heating element of the electric wall-hung boiler is preheated;

[0040] A3, the electric wall-hung boiler adopts polling heating, and heats through the heating element during heating;

[0041] A4, the electric wall-hung boiler adopts the chopping constant temperature model, the gap constant temperature model and the segmental constant temperature model for constant temperature control.

[0042] The electric wall-hung boiler of the present invention adopts a three-phase triangle connection method, and the power lines of the same cross-sectional area. Compared with the traditional electric wall-hung boiler, the power control scheme of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com