Novel powder/colloid formula weighing device

A powder and colloid technology, applied in the field of precision instruments, can solve the problems of inability to take out, irreparable mistakes, etc., to achieve the effect of accurate proportioning, preventing clogging and maintaining dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

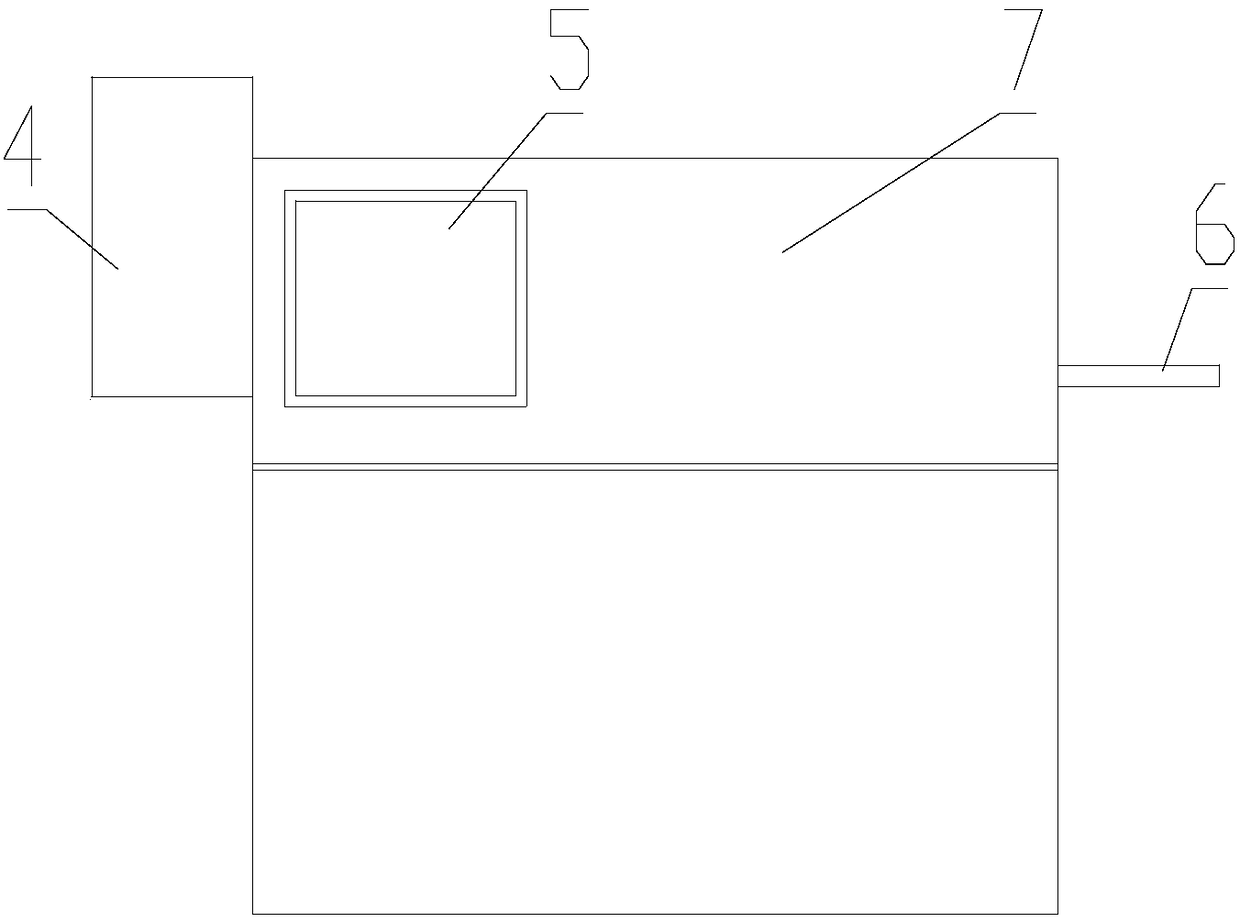

[0020] A new type of powder / colloid formula weighing equipment, which includes an automatic cup loading component, a main working line, a chassis, a plastic cup collection area, and a controller. The main working line is installed inside the chassis, and the automatic cup loading component is installed at the entrance of the chassis The plastic cup collection area is installed at the outlet of the chassis. The controller is an industrial computer, the industrial computer is installed on the chassis, the display is installed on the front side of the chassis, the display is connected with the industrial computer, and the display displays the operating parameters of the industrial computer and equipment.

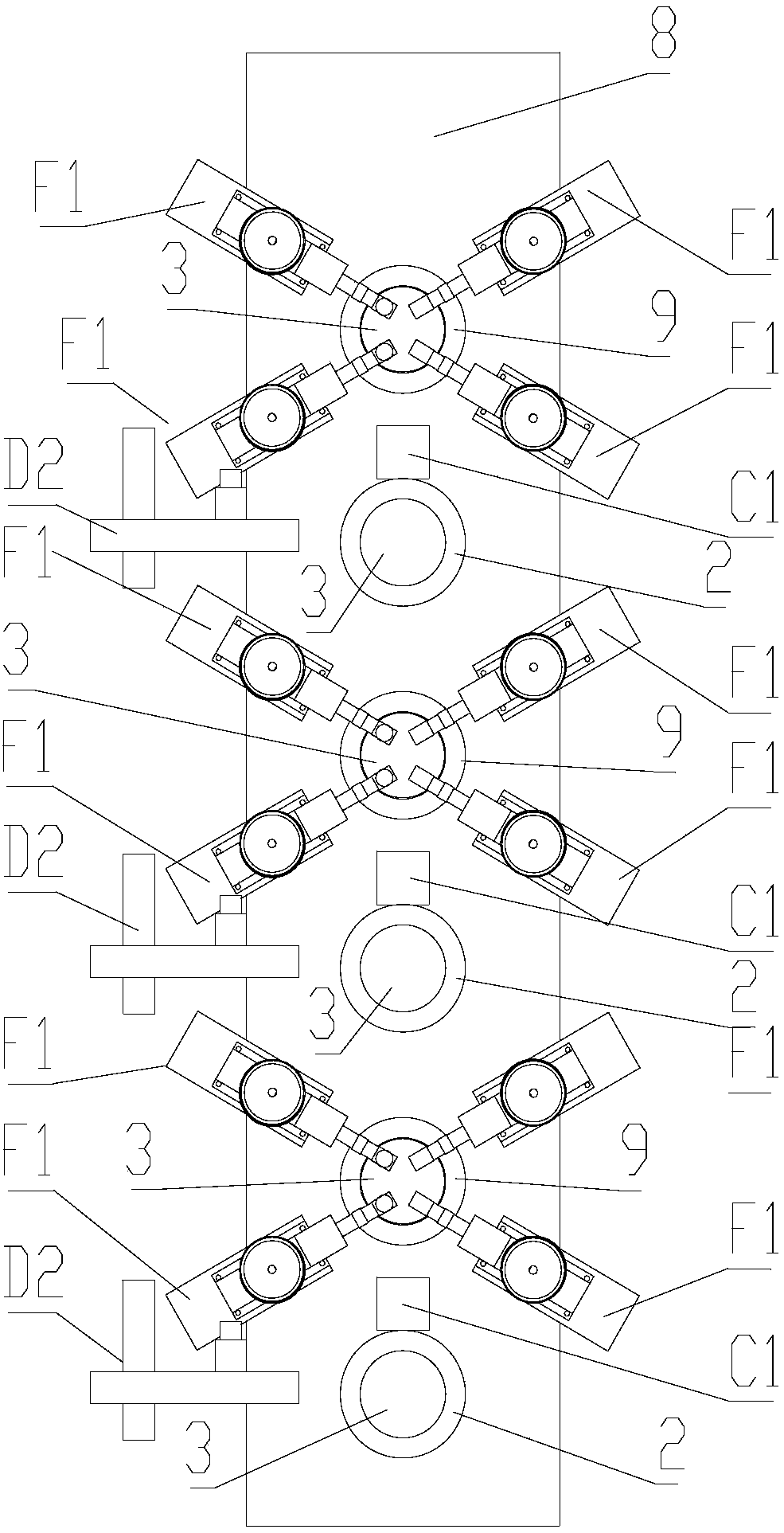

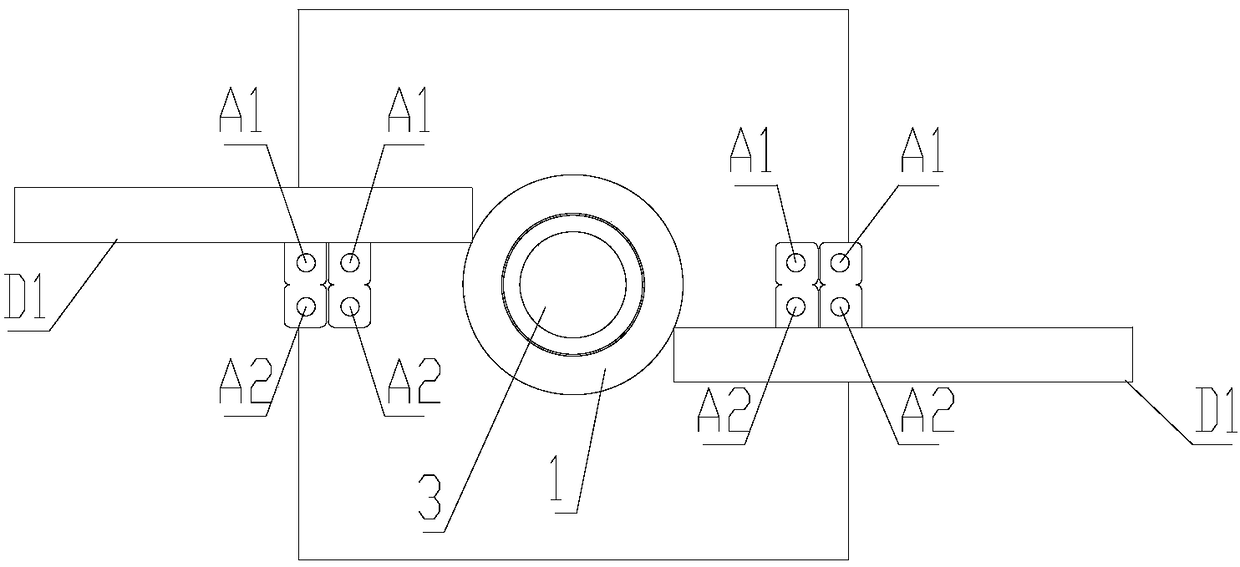

[0021] The main working line includes the base of the working line, the powder making station, the glue making station, and the powder taking station. The num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com