Multifunctional slide trolley of rubber wheel rail APM system with cold slide and limit detection

A multi-functional, trolley technology, which is applied in the direction of railway vehicle testing, mechanical roughness/irregularity measurement, etc., can solve the problems of low labor efficiency, long detection cycle, and large influence of human factors, and achieve reasonable structural design and accurate detection , the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

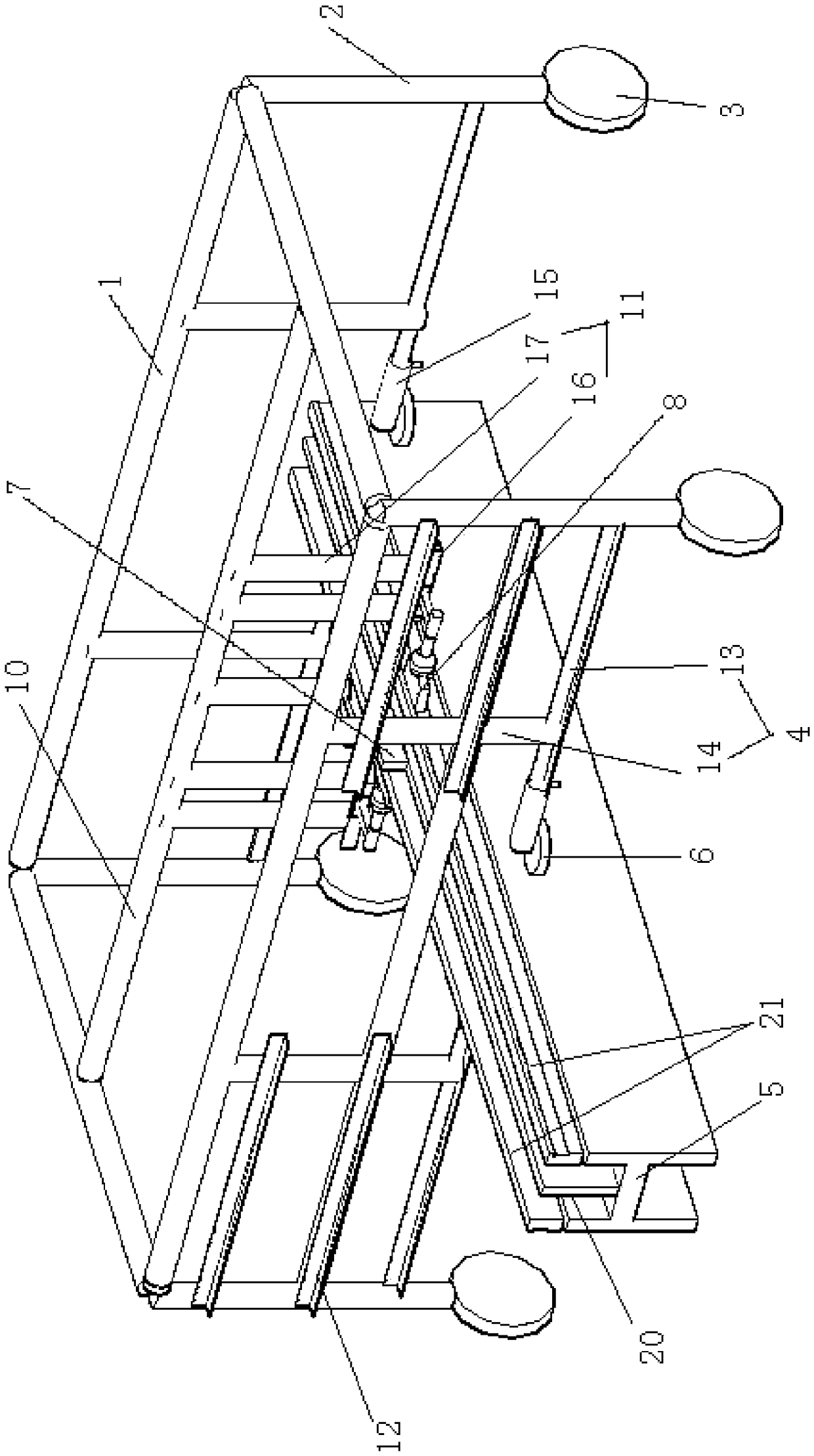

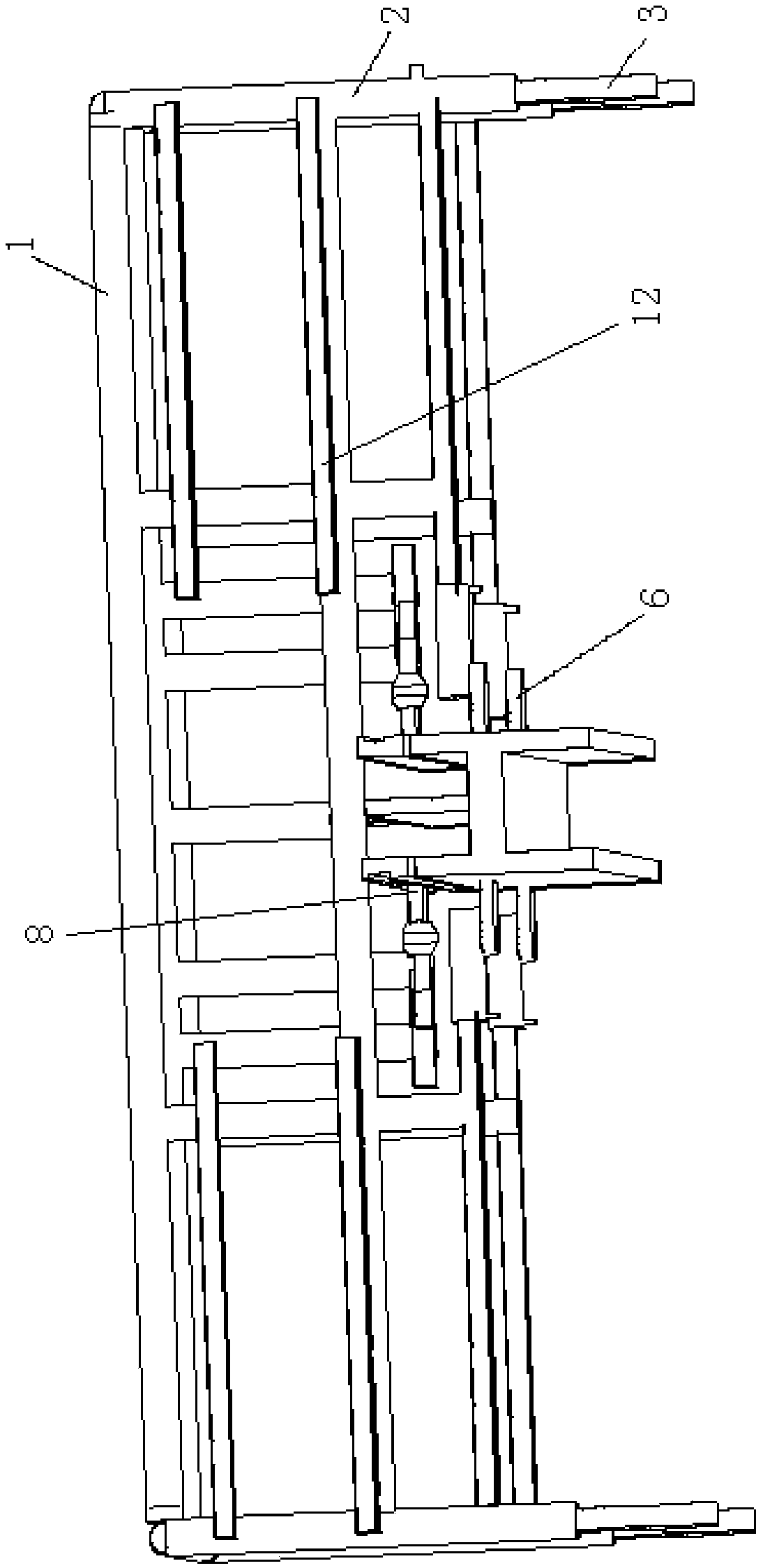

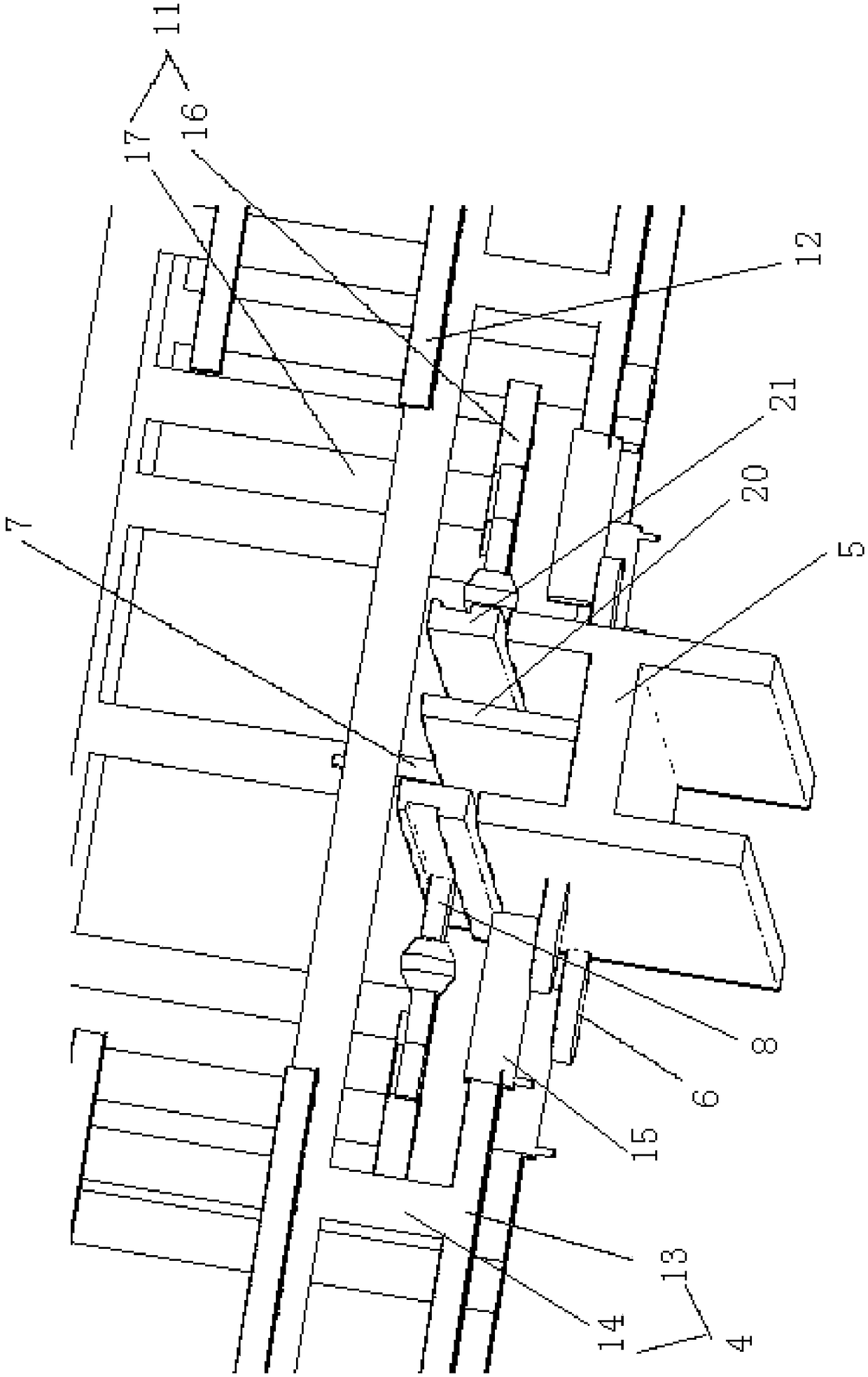

[0021] See attached picture.

[0022] A multi-functional sliding trolley with rubber tire track APM system integrating cold sliding and limit detection, including a sliding trolley frame, and outriggers 2 are distributed around the sliding trolley frame 1, and the bottom ends of the outriggers 2 are respectively equipped with walking wheels 3. There are two sets of guide wheels 6 that guide and roll along the two sides of the guide rail 5 through the guide wheel adjustable bracket 4 between the legs 2 at the front and rear ends. The grounding shoe 7 and the collector shoe 8 matched with the power supply rail 21, the grounding shoe 7 is fixed on the fixed beam 10 in the middle of the frame 1 of the sliding trolley through the adjustable bracket 9 of the grounding shoe, and the collector shoe 8 passes through the collector shoe The adjustable bracket 11 is fixed on the fixed beam 10 in the middle of the sliding trolley frame 1, and the sliding trolley frame is also provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com