Full-automatic cement setting time determination device

A technology for cement coagulation and time determination, which is applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to measure, difficult to compare intuitively, and low degree of intelligence, and achieves reduced work intensity, accurate measurement results, and operation methods. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

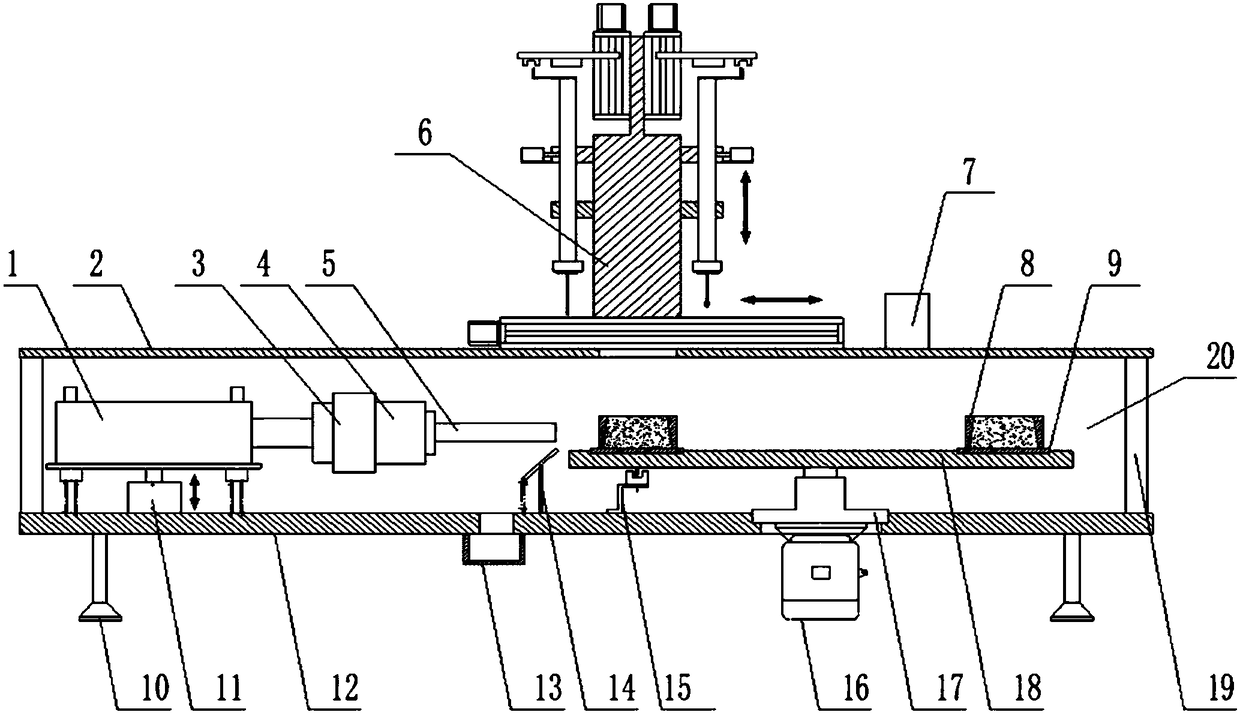

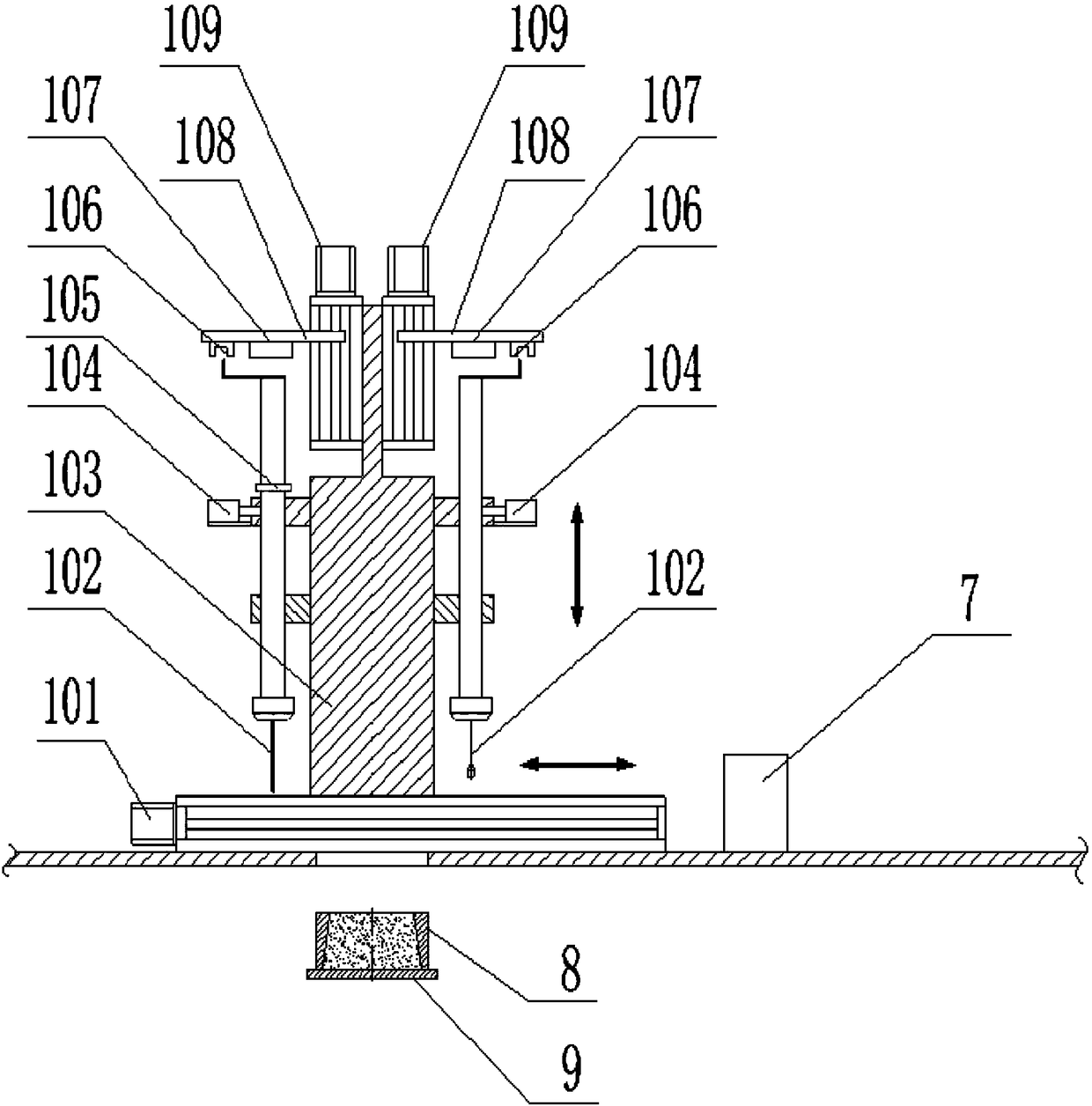

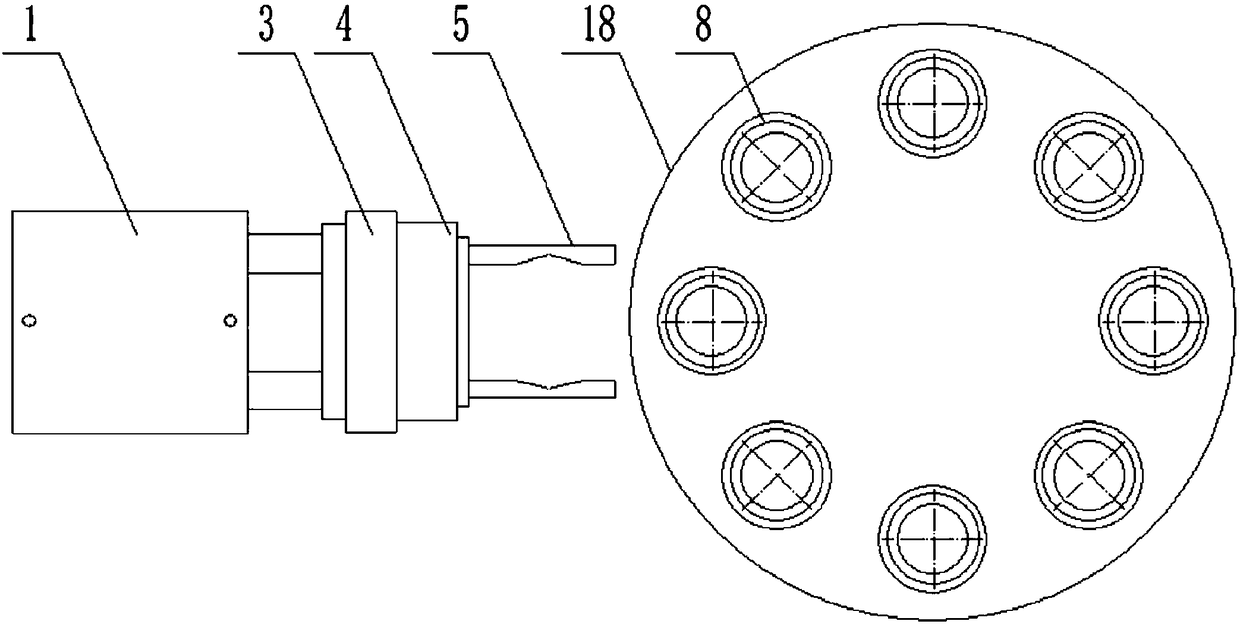

[0025] Such as figure 1 , figure 2 , image 3 As shown, the present invention discloses a fully automatic cement setting time measuring device, comprising a curing box, an overturning mechanism, a turntable lofting mechanism, a detection mechanism 6, a control module (not shown in the figure), and the overturning mechanism, the turntable lofting mechanism They are all arranged in the curing box; the turning mechanism includes a telescopic module 1, a rotating module 3, a clamping module 4, and a clip 5 connected in sequence; the turntable lofting mechanism includes a motor 16 connected to the output end of the motor 16 Turntable 18, mold trial 8, mold trial backing plate 9, said rotating disk 18 is provided with a plurality of sample placement grooves along the circumferential direction, trial mold 8 is placed in said sample placem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com