A sleeve-type insulated wire quick stripper

An insulated wire and sleeve-type technology, which is applied in the field of wire strippers, can solve the problems of increasing labor intensity of operators, high development costs, scratching wire cores, etc., achieve high economic benefits and promotion value, and save time and safety for stripping , Reduce the effect of peeling strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

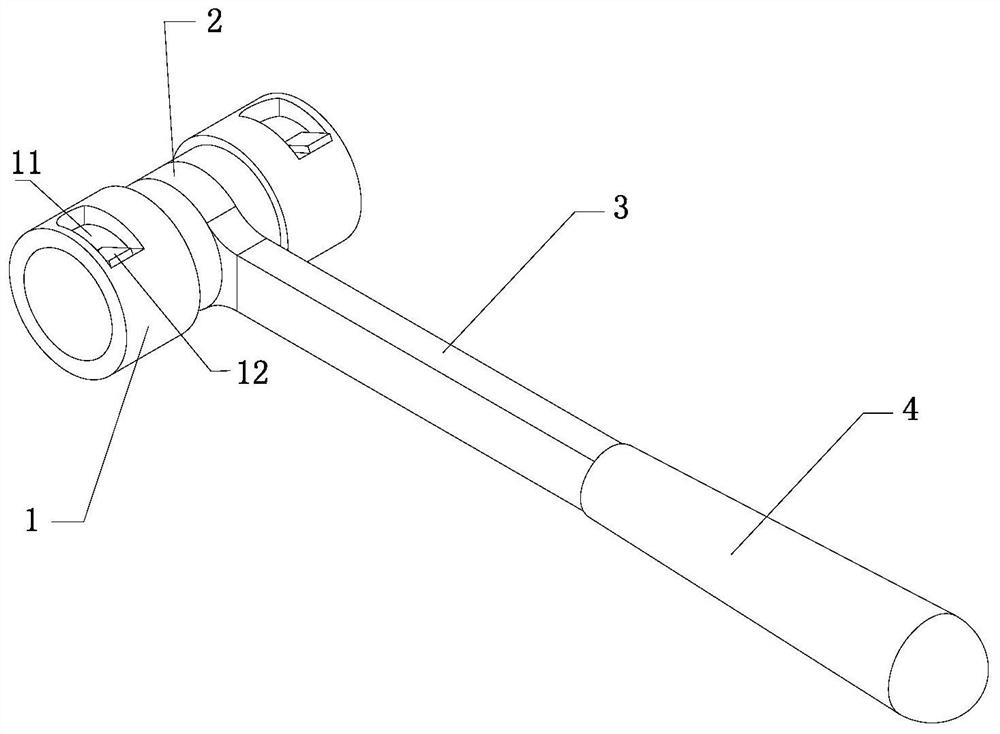

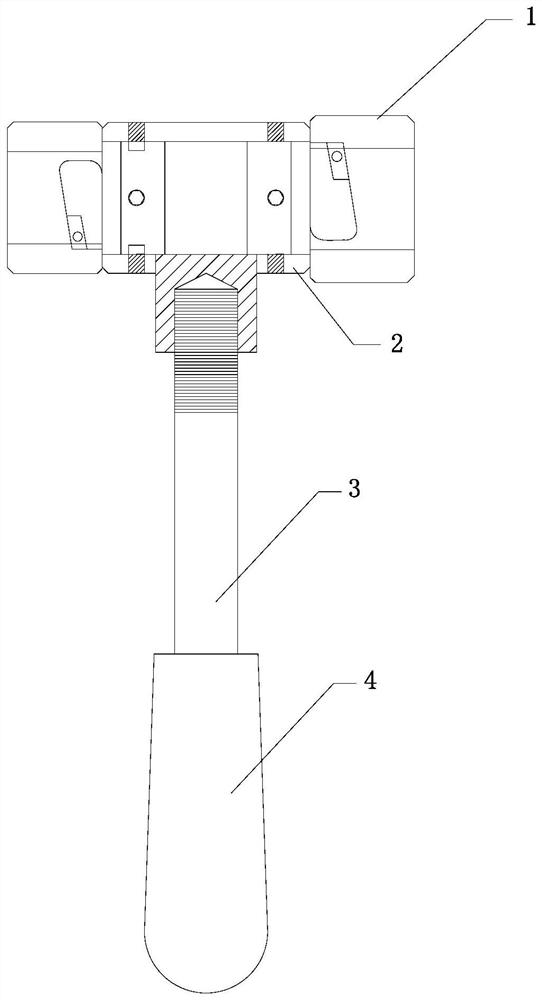

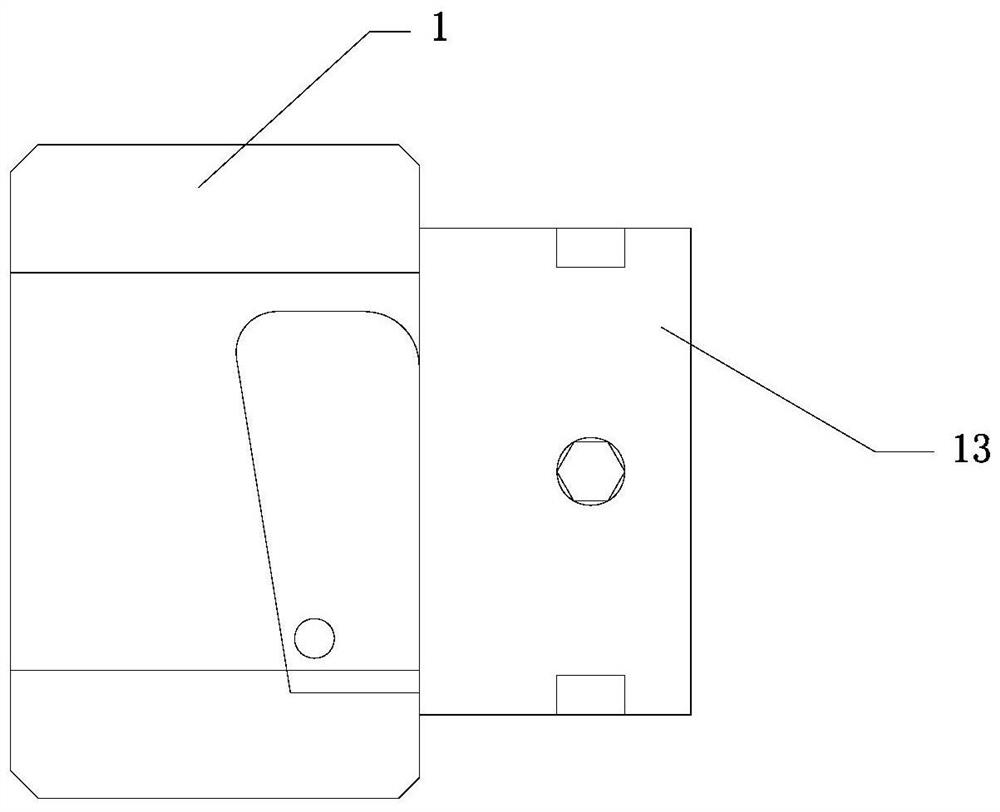

[0023] refer to Figure 1-4 , a sleeve-type insulated wire quick stripper, comprising: two sleeve-type stripping heads 1, a connecting female sleeve 2, an extension rod 3, and a handle 4;

[0024] The two sleeve-type stripping heads 1 are respectively arranged on the two ends of the connecting female sleeve 2 along the length direction, and form a detachable connection with the connecting female sleeve 2; There is a cavity along the length direction of the cavity, and one end of the two cavities away from each other is an open end; the side wall of the cavity has an opening 11 communicating with the cavity and the outside world, and the opening 11 is along the circumferential end of the side wall Connect a sloped inner wall 12; the sloped inner wall 12 extends circumferentially along the side wall and is inclined toward the inside of the cavity; a thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com