Rotation translation push-out type circuit board hot press

A technology of rotation and translation, circuit board, applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems of worker fatigue, worker personal injury, inaccurate vertical displacement positioning of circuit board hot press, etc. Convenience and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

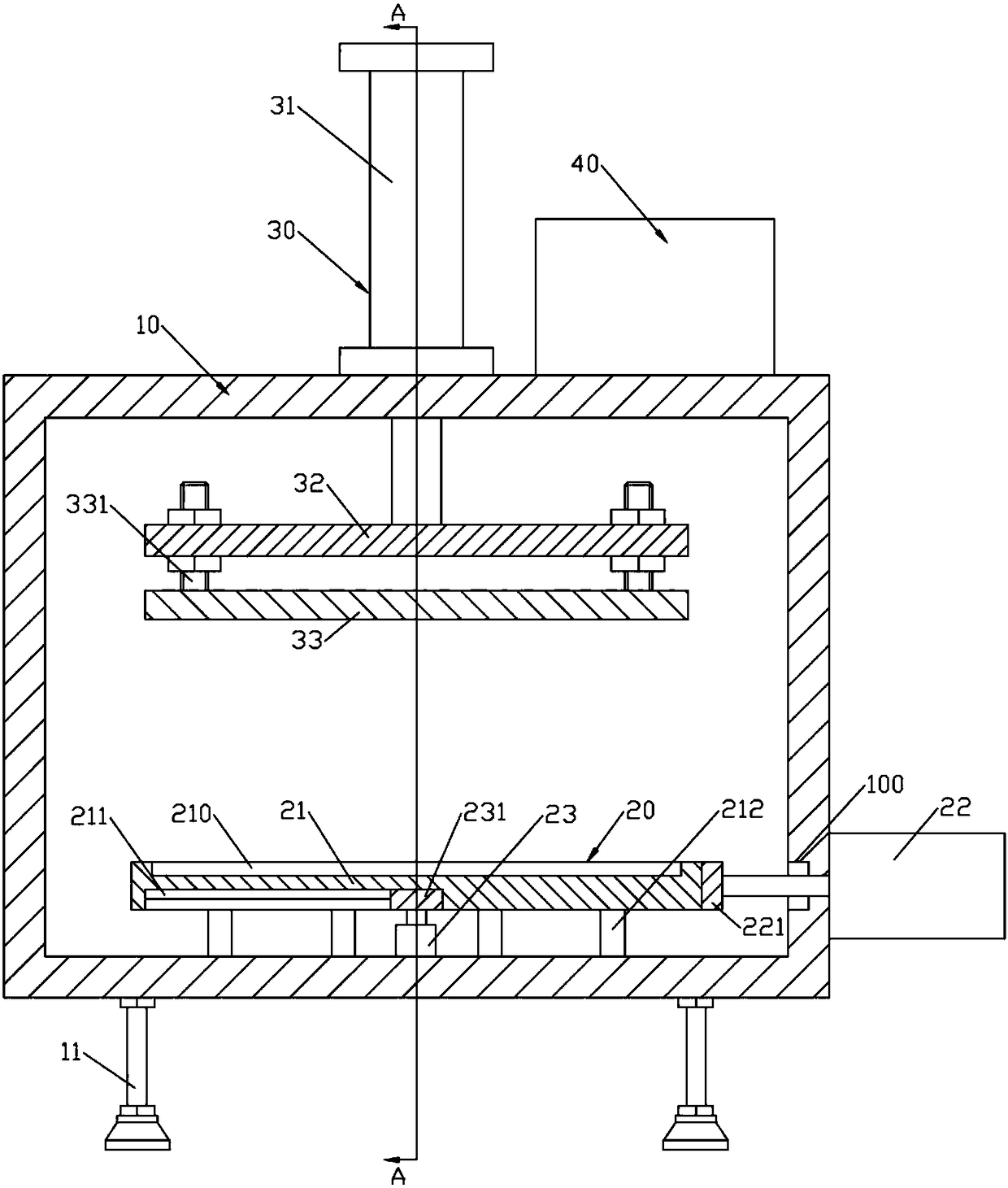

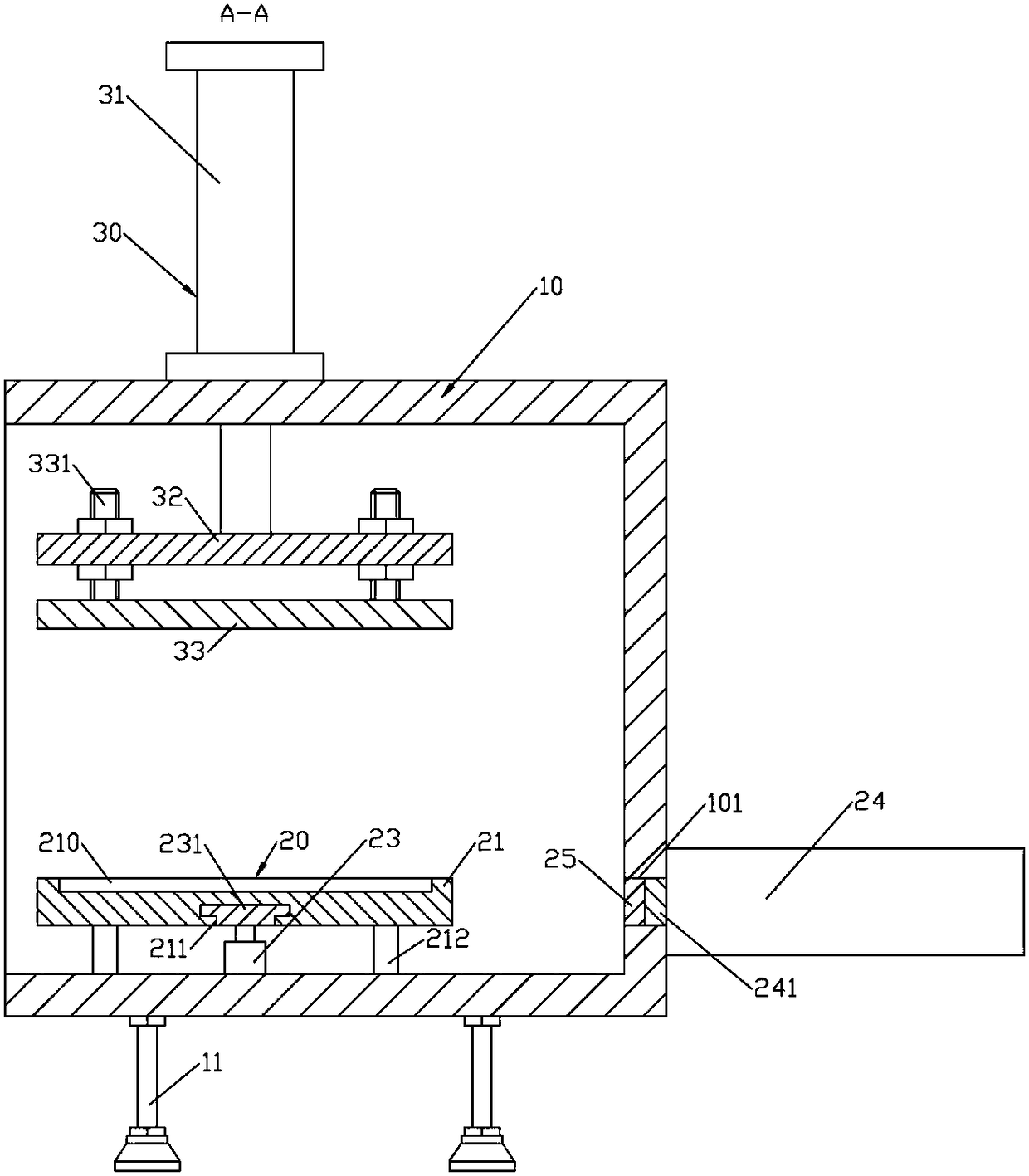

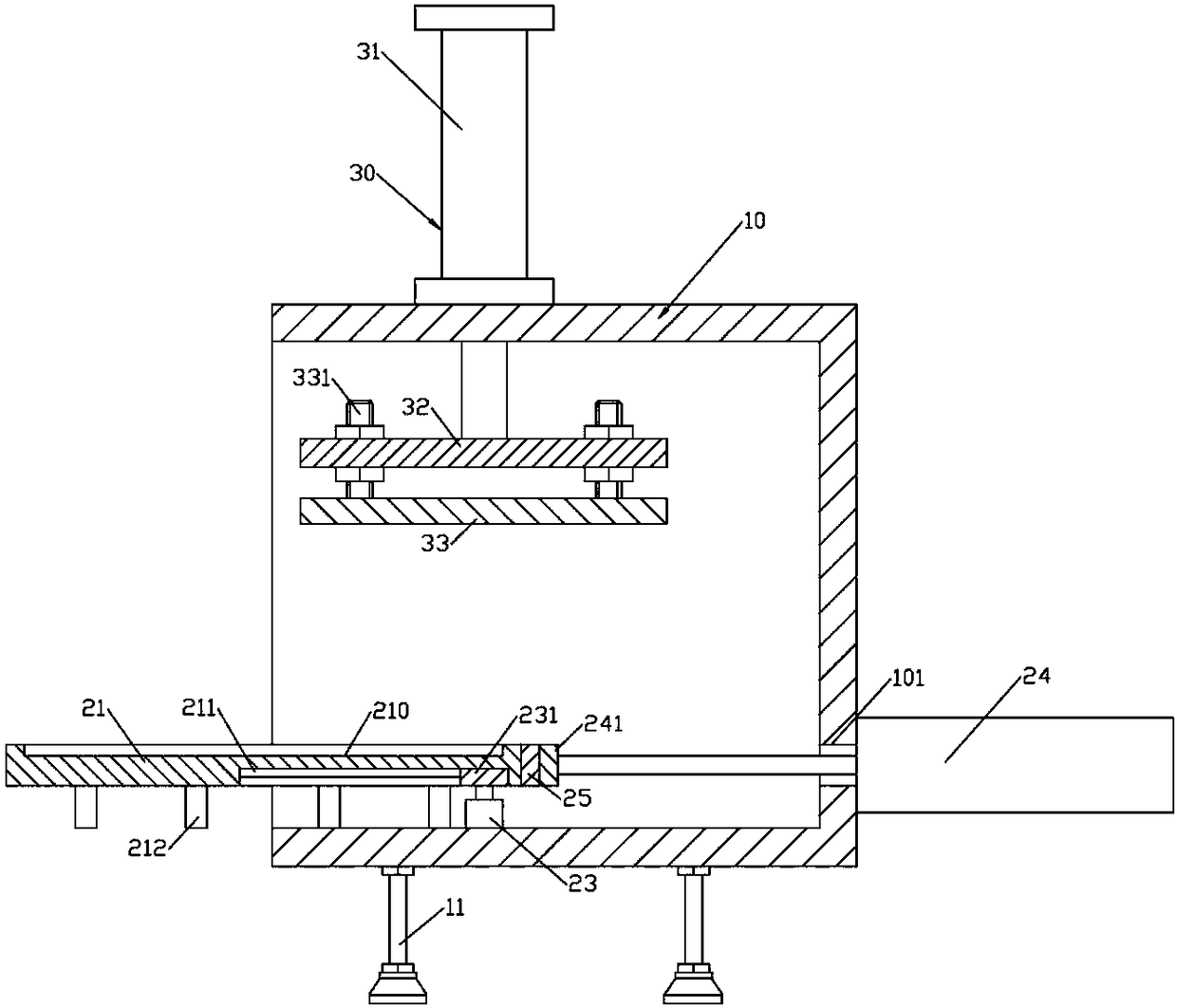

[0017] Such as Figure 1 ~ Figure 3 As shown, a circuit board heat press machine of a rotary translation ejection type includes a support 10, an input and output support device 20, a heat press device 30 and a central controller 40; the support 10 is a rectangular frame with an unsealed front end; the support 10 The lower end surface of the lower end surface is provided with several supporting feet 11; The feeding and discharging support device 20 is arranged on the bottom of the support 10; The feeding and discharging support device 20 includes a rectangular material support plate 21 and a rotary drive motor 23; The middle front part of the inner lower side wall; the output shaft of the rotary drive motor 23 is fixed with a sliding block 231; The width in the left-right direction is greater than the width in the front-to-back direction; the right side wall of the support 10 moves left and right to set a limiting plate 221; the limiting plate 221 is facing the material support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com