A Closed Chain Slider Crank Combination Flower Transplanting Mechanism

A slider and crank technology, applied in the field of agricultural machinery, can solve the problems of unrealistic economic affordability of equipment introduction, difficult realization of double crank conditions, too many rod length constraints, etc., to achieve compact structure, wide optimization range, mechanism flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the specific embodiments of the drawings.

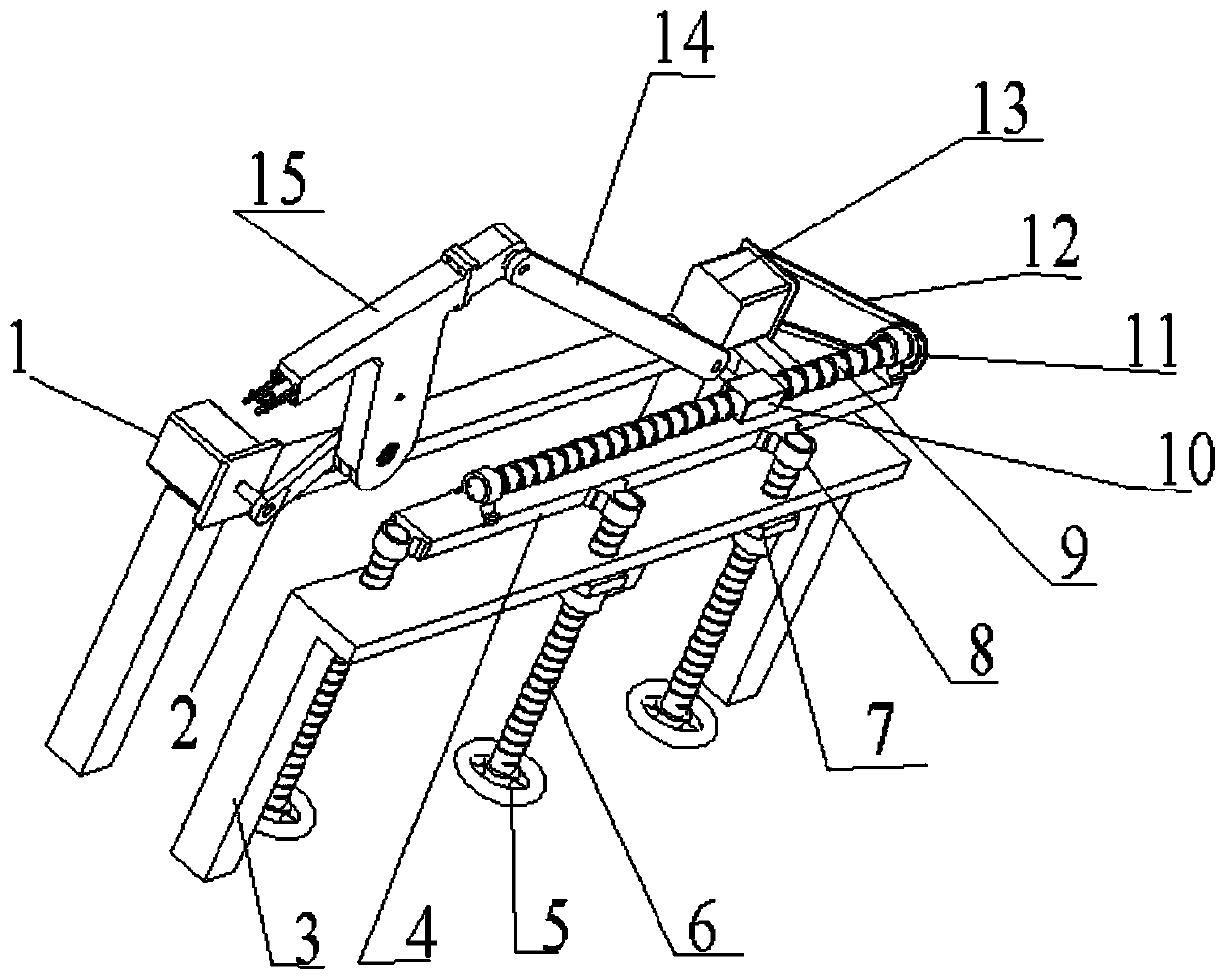

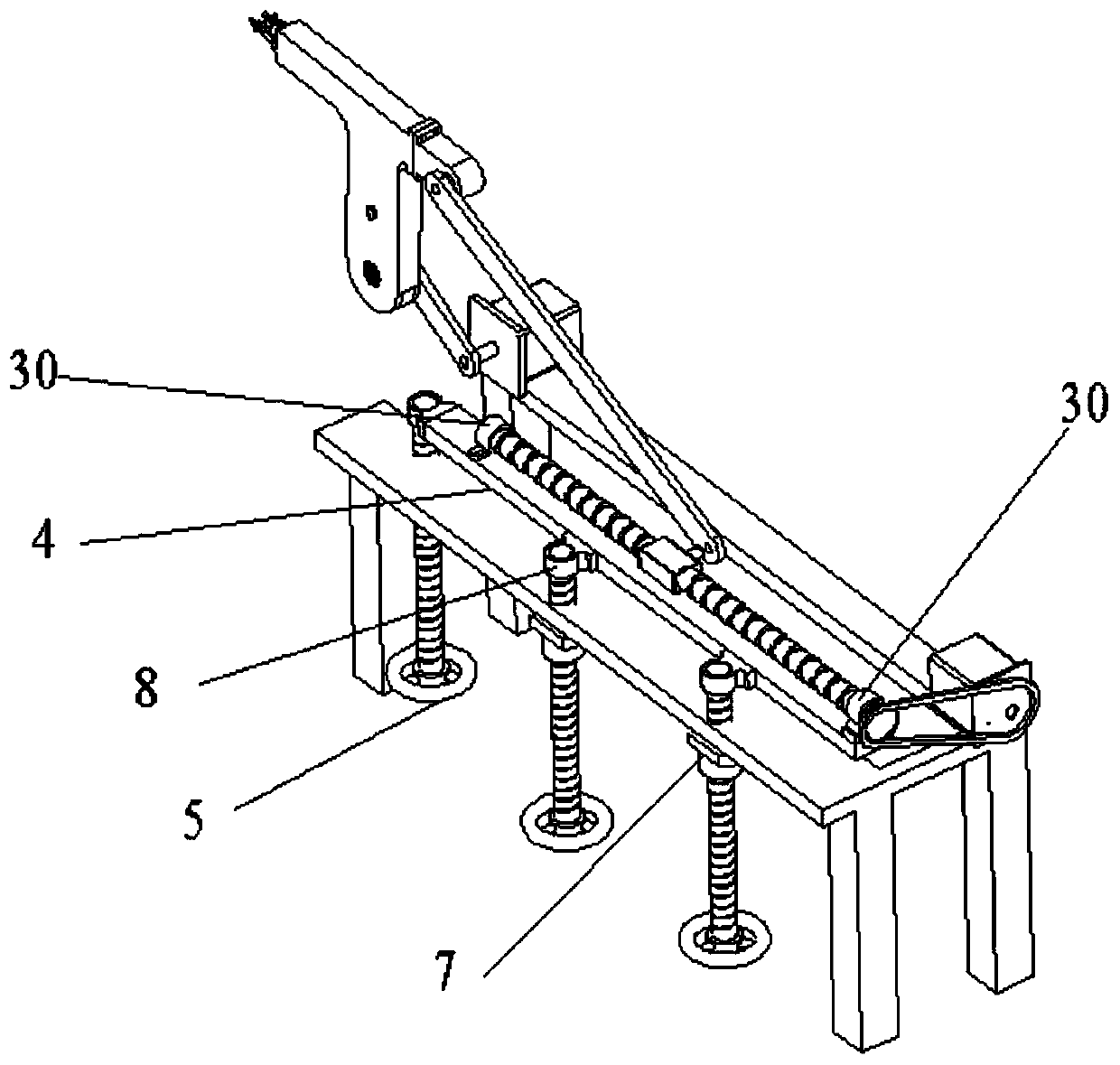

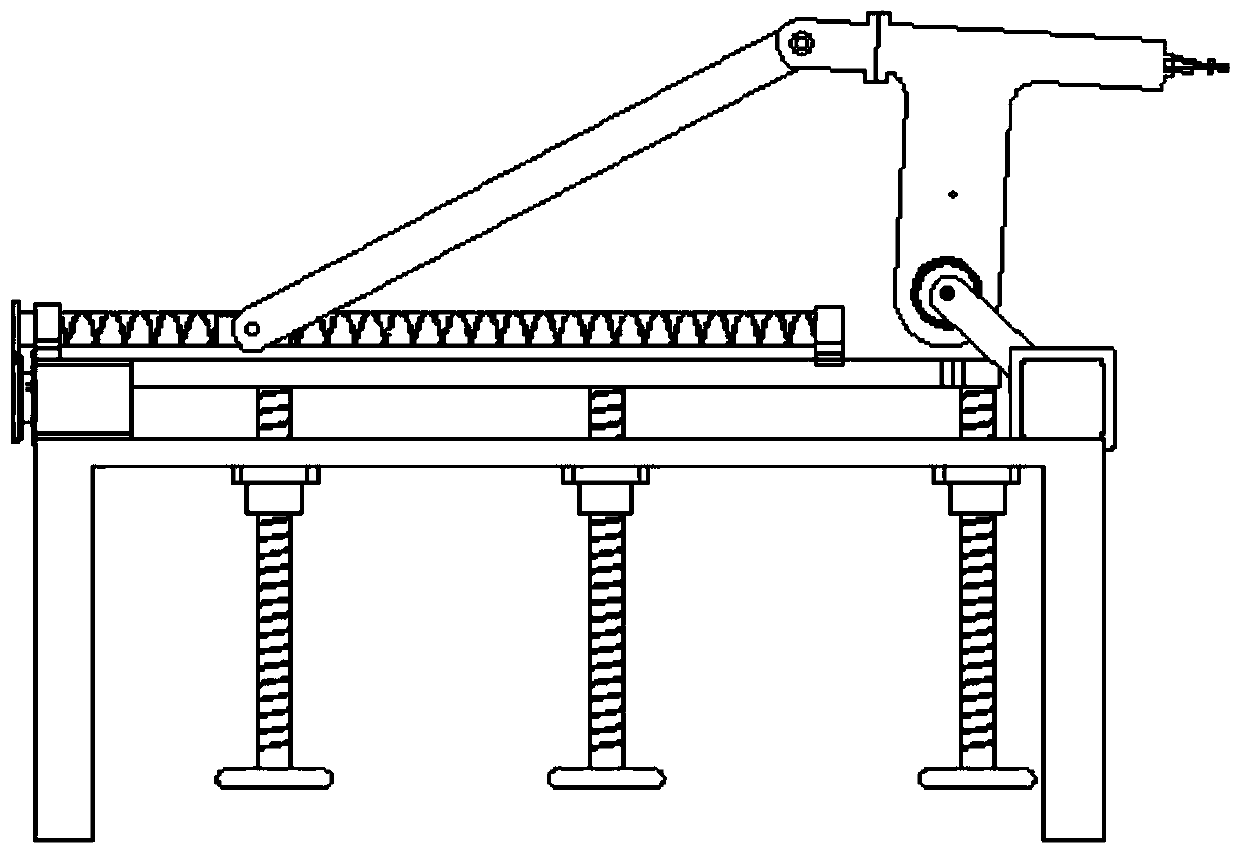

[0027] Such as figure 1 , figure 2 , image 3 , Figure 6-1 with Figure 6-2 As shown, a closed-chain slider crank combined flower transplanting mechanism includes a constant-speed motor 1, a crank 2, a movable support plate 4, a lead screw 6, a double screw shaft 9, a slider 10, a servo motor 13, and a connecting rod 14. And the seedling arm 15; the three through holes of the frame 3 are fixed with screw shaft sleeves 7; the three screw shaft sleeves 7 and the three screw rods 6 respectively constitute a spiral pair; the top of each screw 6 passes through A through hole corresponding to the frame 3, a runner 5 is fixed at the bottom end; three first bearing seats 8 are fixed on the movable support plate 4, and the top end of each screw 6 is supported on a corresponding first bearing seat through a bearing; Both ends of the double screw shaft 9 are support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com